Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA temperature alarm monitoring system can be very useful as a heat monitoring system because it allows you to see and manage the heat levels at all of your remote sites.

"Too much heat" is the most common problem when dealing with computer systems and in maintaining the "cold chain" in food supply chains. But "too cold" is also a very real problem in some climates, as you can have frozen pipes or equipment that won't start.

Temperature monitoring equipment will help you avoid heat buildup at your telecom locations, like huts and other network nodes, by continuously monitoring the site. Temp monitoring systems are also important at less industrial "IT" locations like server rooms and data centers. A central temperature monitoring system will enable you to keep track of critical temperatures at all of your sites that contain important computer gear.

The first consideration you have in evaluating temperature monitoring systems is what type of sensor to use to track room temperature. An analog sensor is superior to digital sensors because it tracks temperature in real-time across a continuous range. Digital temperature monitoring systems, by contrast, will only tell you if the temperature is above or below a predetermined value. There's no way to know how much the temperature has risen (or fallen) beyond the temperature you specify.

Analog sensors are recommended in most cases when you're setting up an environmental monitoring system. Analog sensors offer the ability to check the precise temperature at any time. The only real value of a digital sensor is the ability to send alerts when a specific threshold is crossed. If cost is a big factor in your decision, however, a digital temperature sensor is 100% more useful than nothing at all.

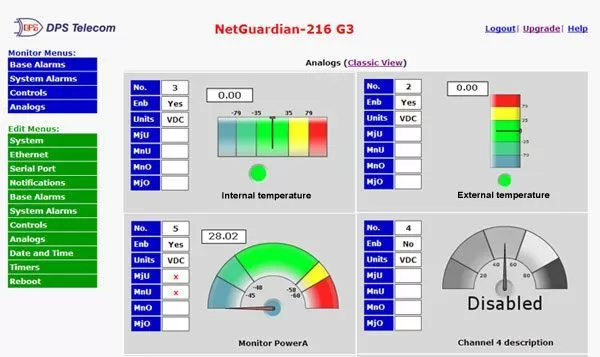

Here, the NetGuardian 216's web interface provides a highly visual system for simple temperature monitoring remotely.

Related Temperature Control Monitoring System Equipment:

- Remote Temperature Sensors, Humidity Sensors, and other sensors

- Vaisala - Network Temperature and Humidity Sensor

- NetGuardian 832A (Large RTU to support multiple temperature sensors and other equipment alarms)

- TempDefender IT (Compact alarm remote designed for server rooms and data centers)

To get the threshold temp alert capability, you need to select the right alarm remote to link your sensors from your remote site to your central office. Network-based temperature monitoring bridges the gap between your sensors, which communicate with analog or discrete contact closures, and your central office.

Actually, a remote terminal unit (RTU) can send temperature monitoring system email alerts to other locations if your company doesn't have a 24x7 network operations center. Whenever your NOC is offline, advanced RTUs will send you temperature alerts through email or text messages.

If your NOC center is open, your RTU can send a protocol-based alert directly to your central master station (commonly an SNMP manager). Your monitoring team is then able to assess the urgency of the temperature threat quickly. From there, you'll know when to deploy the right personnel or take the appropriate remote action.

There are sensors that can be powered directly from your RTU. Some RTUs have a small stereo jack port that supports an external sensor. To the untrained eye, your RTU may have a 7-10 foot wire plugged into it. On the far end of that wire, however, is actually a tiny analog temperature sensor that is entirely powered by the RTU.

You can also use direct single-wire - "D-Wire" - temperature sensors that use one wire to transmit both communication and deliver sensor power. What's more, these sensors are daisy-chainable, allowing you to create one long temperature monitoring circuit. A single RTU input port remotely monitors multiple sensors in this way, allowing you to monitor temperature at several locations within a site.

Another option when using industry-standard external temperature sensors (0-5V or 4-20mA) is to select an RTU that has a built-in 12V power supply. This is the voltage that most external sensors require. Choosing this type of RTU is convenient because you eliminate the need to separately wire and power your sensor.

Running a giant external power transformer brick is a silly proposition when powering a little sensor. Most of the time, your power brick will be much larger than the sensor it powers. You can do much better when building your temperature monitoring system.

You should also consider wireless temperature sensors, which are useful when:

As you can see, RTUs can vary in quality quite a bit depending on the choices you make while researching and purchasing equipment. The sensor-power capabilities of your RTU are important, but there are many other considerations you need to make to select the perfect RTU.

You need to choose a remote temperature monitoring system that has the sensor capacity you need. If you just need to monitor one heat sensor, there's little sense in purchasing a remote with dozens of sensor inputs.

Of course, buying a remote with the exact capacity, or less capacity than you need is even worse. We always recommend buying an RTU with slightly more capacity than what's needed at the time. You never know when you'll want to monitor something else at your site.

We really should spend some time looking at a specific temperature monitoring system offering from a contemporary manufacturer.

Let's begin by reviewing an RTU that's built to handle server rooms, data closets and even telecom environments - the TempDefender IT. It's a small RTU that includes the "D-Wire" sensor interface described above.

While it supports up to 16 sensors total, it's also a good value with just a few sensors because of its daisy chain capability. If you only need a few sensors, you only need to purchase a few sensors. The RTU remains a good value with just a small number of sensors.

If you'd like your temperature monitoring system to call you when alarms occur, there's another small remote you should consider: the NetGuardian LT. This RTU will call your phone (either cellular or landline) whenever a temperature situation demands your attention. If you have just a few areas to monitor, this is a one-box approach to a temperature monitoring system. As you'd expect, the NetGuardian LT is also one of the most cost-effective remotes.

If you have a lot of sites that require temperature monitoring, you'll be much better served to select a larger RTU like the NetGuardian 832A. With 32 digital inputs and 8 analog inputs, it has the capability to monitor most large sites.

To help you better understand how temperature monitoring systems work, let's take a look at a project from DPS Telecom's recent history.

One day recently, Evan called in looking for a small RTU. He had 1-4 sites that needed to be covered by environment monitoring. Evan needed about 8 discrete alarms points, 3 control relays, and 1 serial port for COM port redirect. He also wanted 1-4 generic analog inputs (for collecting sensor data from temperature sensors and other sensors).

A big issue for Evan was windshield time, the hours that technicians spend traveling to and from remote sites. For Evan's company, some sites were up to two hours away from the central office. This was a problem because it led to huge fuel consumption and extra working hours for techs.

Evan had a couple of sites that were solar powered with backup generators. The generators would run whenever the solar panels did not create enough electricity. The generators eventually started having problems when they had to switch on and off a couple of times a day.

If the generator did not start, they would have the inverter cut out. This would prevent the batteries from draining to the point of damage. This would cause the site to go down.

We received this email from Evan, describing more of his need a temperature monitoring system:

"This is a remote communications site with a microwave link and Ethernet connection to our own intranet. Likely power the unit off 110 VAC, though we might prefer to put in a DC-DC converter off the +48 VDC bank unless your unit will run off as high as +60 VDC. Site is solar powered with 4 Outback charge controllers, 4,000 Ah of batteries, 15 KVA of Outback inverters and a 30 KVA generator.

We would want to monitor:

Control via relays:

Nice to have:

Sincerely, Evan"

Related Topics:

Generator monitoring system project