Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMany remote monitoring solutions include a cellular remote. This enables your techs to maintain a constant connection to their gear and facilities in real-time.

Constant awareness of your site status is your key to success. If you can't see what's happening out there, you'll be driving out to sites way more than you need to. This waste of time and fuel is called windshield time. Worse yet, you might even have a small problem (HVAC failure) that grows into a massive failure (equipment damage & thermal shutdown).

Temperature Monitoring is one of the first things you should monitor. It's not hard to track, and simple temperature measurement can detect a variety of problems. These include HVAC failure, insufficient HVAC for thermal load, fire, & door open.

Whether you work in a hot or cold climate, it is very important to monitor the environmental conditions around your revenue-generating equipment. You must be able to alert your crews in the field of any potential network threats. Every small network problem is a race against time. You must respond quickly to all issues.

Imagine you are running 15 remote sites in the Southwest region. Your air conditioning unit in Site 3 failed.

You don't have adequate monitoring of the unit or temperature. You are completely unaware of the damage. Your first indication of any problem will be thermal shutdown, angry customers, and an angry boss.

That's a situation where you have zero alarm monitoring. But most people have at least some alarm monitoring. Consider this more likely example:

Imagine your remote monitoring system collects alarm data, but your technicians have to return to the NOC to check status. Then, they have to drive out to the site to determine the cause, because your alarm messages don't have adequate detail. After visiting the site once, you tech realizes he doesn't have the right replacement part.

He returns to the NOC to gather parts to perform repairs. And finally, he returns to the remote site. All of this confused driving around can add up to literally hours before the problem is solved.

Consider all of the damage that can be caused by high temperatures. The expense adds up very quickly.

What if that same tech was able to get an instant SMS alert with the exact location ("Clark Mountain Site"), the exact alarm ("Temp = 95 F"), and the cause ("HVAC failure")? Now, you have no unnecessary trips and no budget dollars wasted on fuel and wages. Because you were able to fix the problem in a timely manner, your remote gear isn't damaged and your network stays online. Your customers are happy, and your boss is happy.

As a trusted in-house temperature monitoring solutions manufacturer, we highly recommend that you monitor remote temperatures. That's why most of our RTUs include at least one internal temperature sensor. Excessively high or low temperatures can result in gear damage, service downtime, or network outages.

Inadequate monitoring of a site or having no monitoring system in place at all can cause you to be unaware of threats to your equipment. By the time you've determined the root cause, you've already lost money resulting from equipment damage and potential equipment failure. You must know when your temperatures are fluctuating at certain high or low points so that you may be able to fix the problem immediately before it gets any worse.

Some of your very remote sites may not have IP/LAN, but they do have cellular network coverage (GSM/CDMA). In this case, deploying a remote temperature monitoring system with SMS capabilities is the perfect-fit solution. When your temperature sensors are tripped, the RTU reports via wireless GSM/CDMA as SMS. This text message goes straight to your technician's phone.

You can also send SNMP traps encoded into SMS messages that are received by an SMS receiver box inside your network. This is a very clever way to avoid firewall problems because SMS is a non-IP link to your RTU. This is far superior to establishing an expensive IP connection or risking your security risks by punching a hole in your firewall. These are huge problems that no company ever wants to encounter.

Remote temperature monitors (cell phone-enabled) can avoid those risks by simply reporting alarms to the receiver device's phone number using SMS text messages - the same way cell phones are used to send text messages. During this process, the receiver device receives the text messages, interprets and translates them into standard SNMP traps, and reports them via intranet LAN to your SNMP manager.

You can choose to deploy temperature sensors that output discrete threshold alarms or an analog value. Discrete threshold sensors are similar to thermostats. They allow you to preset high- and low-point thresholds and, when presets are exceeded, you would get a contact closure alarm.

For example, you would preset your thermostat to a certain low or high temperature at home. Once your house gets too hot or too cold, the heater or air conditioning system would automatically turn on.

The downside of going with this option is, if your threshold was set to 80 degrees F, you would only know that your high-temperature alarm was tripped. You know the temperature is above 80 degrees F - but it could be anywhere from 81 degrees F to 181 degrees F. You won't know if you have minor HVAC problem or a fire.

On the other hand, analog sensors offer much more detail. You'll be able to see the current temperature at your site (usually +/- 1 degree F). This doesn't mean, however, that you'll have to start at a sensor reading all day. If you choose a smart RTU, you can use analog values to send alarms based on user-configurable thresholds (low critical, low, high, high critical).

This way, you'll get alerts via text and email when the temperature falls out of spec. Then, you can monitor the escalation (or plummeting) of your temperature and use your judgment to react appropriately to the situation.

You should not just monitor and manage your RTU's temperature. Monitoring the temperature around your important equipment is also key. For example, imagine if the outside temperature is 110 degrees F and your HVAC stopped working. With the right temperature probes in place, you will get a clear picture of how each piece of equipment is beginning to overheat.

With an SMS-equipped RTU, you can be notified of the heat problem as soon as the temperature goes over one or both of your preset thresholds. With this knowledge, you know you better dispatch a technician fast!

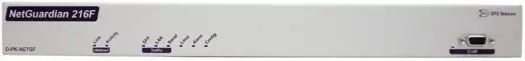

DPS has other non-LAN RTUs available for sites where both LAN and cellular are unavailable. If your site happens to have T1 or fiber-optic connection, the NetGuardian 216T (T1) or NetGuardian 216F (fiber) would be the ideal RTU to monitor your site. With these RTUs, you won't need cellular capabilities at all.

NetGuardian 216T.

NetGuardian 216T.  NetGuardian 216F.

NetGuardian 216F. As you can see, temperature monitoring involves a fairly complex array of options. You need an RTU and (usually) a master station. You have to consider LAN vs. cellular vs. fiber vs. T1 transport. You also have budget constraints.

DPS can help you save your time, energy, and money by deploying a perfect-fit, remote site monitoring solution. You have literally hundreds of options when choosing an RTU, and there are dozens of temperature sensors out there. We'll use our expertise to help you choose the right system for monitoring. We know that "monitoring" will probably include not only temperature but also everything else that you should be monitoring at each of your facilities.

DPS can create custom units through vertical integration. This strategy concentrates on the control of manufacturing, which is done in-house versus outsourced manufacturing. DPS Engineers and Production Staff cooperate to design and manufacture the perfect RTUs for your monitoring needs.

This process consists of cutting, bending, and powder coating the metal case; assembling the circuit boards; and having finished RTUs go through rounds of tests by different technicians for quality assurance. So if you need an RTU with a very unique requirement, DPS can definitely customize one for you.

The D-Wire sensor can be used to monitor a variety of environmental parameters from temperature to humidity. Its "ease-of-use" and "plug-and-play" design makes it hassle-free to set up. There's no need to tinker with setting up the D-Wire sensor since the D-Wire sensor is automatically recognized by DPS RTUs when plugged into the DPS RTU's D-Wire port.

Because the D-Wire sensor is powered directly by a DPS RTU's D-Wire port, it does not need to be connected to a power source. The most notable feature of a D-Wire sensor, when compared to other analog sensors, is that the D-Wire sensor can be daisy-chained up to a maximum of approximately 600 feet.

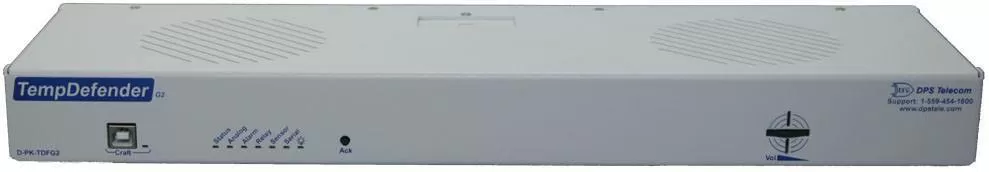

The numbers of D-Wire sensors that can be daisy-chained on a DPS RTU like the TempDefender G2 is 16. Compared to 3rd party sensors, the features found in the D-Wire sensor makes the D-Wire sensor much more economical.