Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA supervisory system can save you a lot of money and increase profitability. However, your SCADA implementation (if not done properly) can be a sinkhole of cost overruns, delays, and limited capabilities.

Let's go over some of the essentials of SCADA network technology and the main guidelines for evaluating SCADA systems. This way you can implement a SCADA network that best fits your needs.

The SCADA meaning in the engineering of networks is not related to a specific technology, but to a type of application.

Supervisory Control and Data Acquisition (SCADA) is a computer system that gets real-time data about a system in order to control that system is a SCADA application.

A SCADA network has two main elements:

You can use SCADA to manage any kind of gear.

Normally, SCADA systems are used to automate complex industrial processes where human control is impractical. Systems where there are more control factors and more fast-moving control factors than individuals can comfortably deal with.

Here are some of the examples of where SCADA networks can be implemented:

Facility managers use SCADA to control HVAC, refrigeration units, lighting and entry systems.

This list barely covers all the possible applications for SCADA systems.

You can find SCADA system projects in many different industries and public infrastructure - simply anywhere automation increases efficiency.

Also, these examples don't really cover how deep and complex SCADA data can be. In every industry, managers need process data and control multiple factors and the interactions between those factors. SCADA systems provide the capabilities and the computational power to track everything that's important to your operations.

Do you work in one of the previous fields listed?

Maybe you don't, but think about your operations and all the aspects that can affect your bottom line.

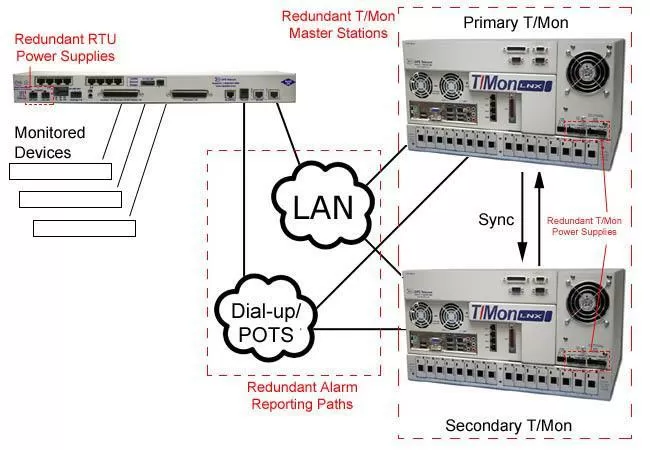

SCADA network systems are normally constituted of four components:

The previous SCADA components perform the following SCADA network functions:

First, a real-life SCADA network typically needs to monitor hundreds or even thousands of sensors. Some sensors measure inputs into the system - water flowing into a reservoir for example. And some sensors measure outputs - like valve pressure as water is released from the reservoir.

Some of those sensors measure simple events that can be detected by a straightforward on/off switch, called a discrete input (or digital input). In real life, are used to measure simple states, such as whether the equipment is on or off, or tripwire alarms, like a power failure at a critical facility.

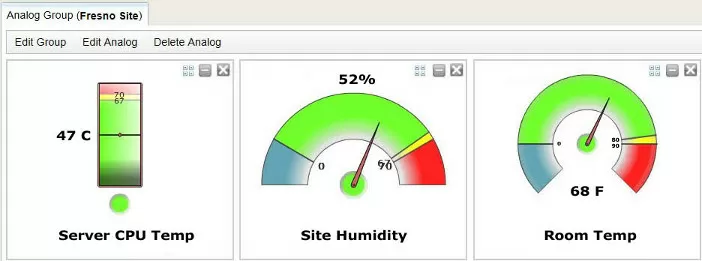

Some sensors measure more complex situations where exact measurement is important. These are analog sensors, which can detect continuous changes in a voltage or current input. Analog sensors are used to track fluid levels in tanks, voltage levels in batteries, temperature and other factors that can be measured in a continuous range of input.

For most analog factors, there is a normal range defined by a bottom and top level. For example, you may want the temperature in a server room to stay between 60 and 85 degrees Fahrenheit.

So, if the temperature goes above or below this range, it'll trigger a threshold alarm. In more advanced systems, there are four threshold alarms for analog sensors. These thresholds define Major Under, Minor Under, Minor Over,and Major Over alarms.

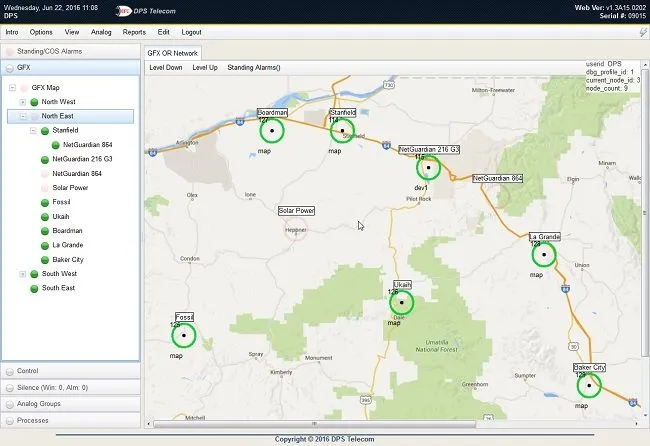

It's important to be able to monitor multiple systems from a central location. So, you need a communications network to transport all the data collected from your sensors.

Early SCADA networks communicated over radio, modem or dedicated serial lines. Today the trend is to put SCADA data on Ethernet and IP over SONET. For security reasons, SCADA data should be kept on closed LAN/WANs without exposing sensitive data to the open Internet.

SCADA networks don't communicate with just simple electrical signals, either. SCADA data is encoded in protocol format. Older SCADA systems depended on closed proprietary protocols, but today the trend is to use open, standard protocols and protocol mediation.

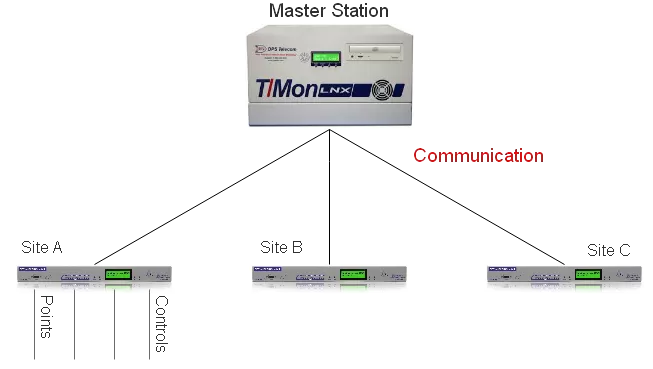

Sensors and control relays are very simple electric devices that can't generate or interpret protocol communication on their own. Therefore an RTU is needed to provide an interface between the sensors and the SCADA network.

The RTU encodes sensor inputs into protocol format and forwards them to the SCADA master. In turn, the RTU receives control commands in protocol format from the master and transmits electrical signals to the appropriate control relays.

A SCADA machine that reports to human operators over a specialized computer is variously called a master station, an HMI (Human-Machine Interface) or an HCI (Human-Computer Interface).

The SCADA master station has multiple functions. It continuously monitors all sensors and alerts the operator when there is an "alarm" - that is, when a control factor is operating outside what is defined as its normal operation. The master then presents a comprehensive view of the entire managed system, and gives more detail in response to user requests.

The master also performs data processing on information gathered from sensors - it maintains report logs and summarizes historical trends. An advanced SCADA master can add a great deal of intelligence and automation to your systems management, making your job much easier.

If you have a sufficiently modern master unit, your SCADA network system can completely regulate all kinds of industrial processes automatically (without any human intervention). But, of course, you can still manually override the automatic controls from the master station.

So, for example, if too much pressure is building up in a gas pipeline, the SCADA system can automatically send a command to open a release valve. Electricity production can be adjusted to meet demands on the power grid. Even these real-world examples are simplified - a full-scale SCADA network can adjust the managed system in response to multiple inputs.

Now you know what SCADA can do for you. But, do you know how to get its full benefits?

Evaluating complex systems can be tricky - especially if you have to learn a new technology while still doing your everyday job. However, you've got to be able to make an informed decision, because the stakes are incredibly high.

A SCADA network is a major, business-to-business purchase that your company will live with for maybe as long as 10 to 15 years. When you make a recommendation about a permanent system like that, you're laying your reputation on the line and making a major commitment for your company.

And, as much as SCADA can help you improve your operations, there are also some pitfalls to a hasty, unconsidered SCADA implementation.

So, let's go over some guidelines for what you should look for in a good SCADA network.

Your RTUs need to communicate with all your on-site equipment and survive under the harsh conditions of an industrial environment. Here's a checklist of things you should expect from a quality RTU:

You know how hard on equipment your remote locations can be. Keep in mind that your SCADA network needs to be the most reliable element in your facility.

Your SCADA master should display information in the most useful ways to human operators and intelligently regulate your managed systems. The following is a checklist of SCADA master must-haves:

Support for multiple protocols and equipment

Early SCADA systems were built on closed, proprietary protocols. Single-vendor solutions aren't a great idea - vendors sometimes drop support for their products or even just go out of business. Support for multiple open protocols safeguards your SCADA network against unplanned obsolescence.

Building the right SCADA system for your business isn't that simple. It's easy to spend more than what you really need. However, there are also many opportunities to save money and improve operational efficiency that you don't want to miss.

It's also hard to learn everything you need to know and still make sure you're focusing on your daily job.

We can help you plan your SCADA implementation, with expert consultation, training, and information resources. Our equipment is built with the capabilities you need, and don't forget that we're committed to helping you get the best SCADA system for your specific needs.

There's no risk when you decide to work with us. Your SCADA network is backed by our 30-day, no-risk, and money-back guarantee.

So, you can test your new system at your site for 30 days. If you're dissatisfied for any reason, just send it back for a full refund. We don't want your money unless it's your perfect-fit solution. It's that simple.

Contact us today and let's dive into your SCADA implementation together.