Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA cell site is a perfect example of facility that absolutely demands remote monitoring technology:

Before we get into remote monitoring, let's pause to consider what sorts of hardware you're likely to have at any cell tower site...

Because the mission at each cell site is similar, nearly every cell site has the same basic components. I joke with my clients that I've been to "the same site" all over the country. The only difference seems to be the local geography, weather patterns, and what type of critters try to cause mayhem.

If you've visited any of your company's or agency's cell sites, it's likely that you saw the following equipment types that are common at cell sites:

This list is just the basics of what you should be monitoring and automating at any cell tower site. There may be other specific items to address based on your industry, location, or other aspects of your situation.

It's obvious that you need good monitoring to protect all of this equipment and your service reliability, but how do you go about doing that?

With our list of "what equipment to monitor?" out of the way, we can now drill down to which alarms and levels we want to monitor within each device/system.

The short answer here is: You need to monitor everything that could conceivably be useful in preventing a costly incident. Expense happens when something breaks, when you have to make an emergency site visit, and especially when your users or customers suffer.

By collecting this data on a regular basis, you can be alerted to potential issues before they become costly problems. Automating the monitoring of cell tower sites is essential for ensuring service reliability and protecting.

OK, so now we've covered both the equipment we have at our cell tower site and the main items that we want to monitor for each. Next, we need to talk about how you'll choose the right RTU (Remote Telemetry Unit or Remote Terminal Unit) for your site.

An RTU is a computerized device that collects data from remote sensors and sends it back to the main monitoring system. It's essentially a "gateway" for all of your cell tower site data, allowing you to monitor everything from one place and make sure all systems are running smoothly.

By taking the time to research and choose an appropriate RTU for your cell tower site monitoring needs, you'll be able to ensure reliable service and protect your investment in equipment and personnel.

As with almost anything, it can be useful to step through the above buying criteria with an example product. This will help you as you start your own product research.

Let's use the NetGuardian RTU line as one example. We won't look at a specific model, but rather the various different models that are available under that brand name. Because we're dealing with a hypothetical cell site, we might need different capacities depending on the specific site that requires monitoring.

First up on our shopping list is "compatibility". Let's say that we've counted 13 different contact closures to monitor among our various site gear. We might choose a NetGuardian M16, which (as the name implies) has 16 discrete inputs to capture those contacts. We'll have 3 to spare for future site growth.

If we have a lot of analog levels to monitor, like site battery voltages or fuel readings, we might instead choose a larger model like the NetGuardian 832A. It has 8 analog inputs and 32 discrete inputs (discrete inputs are a huge driver of hardware cost, so it's better to have too many than too few).

Most NetGuardians have at least a small handful of relay outputs, and you should match these to the number of devices at your cell tower site that support this control method. It's common to use RTU control relays to control generators or perhaps even unlock electrically actuated doors.

Second on our list is "durability". The NetGuardian line prides itself on its industrial-grade components and "industrial temperature rated" (optional) builds, built-in surge suppression (opto-isolated inputs) and optional accessories for lightning-prone areas (SPDs), and ability to operate in temperatures ranging from -40°F to 158°F. You can trust these devices to survive the rigors of the cell tower environment.

Third is "security". NetGuardian features a variety of secure protocols, such as TLS 1.2 on the latest "G6" models, to protect both your monitoring data and configuration settings. You'll also be able to choose from a variety of authentication methods, such as local access control lists or RADIUS authentication, to ensure that your monitoring data is kept safe.

Fourth is "reliability". NetGuardian has been around for decades, and it's a name that engineers have come to trust over the years. It's amazing how often I run into people considering a purchase who say, "I know I've seen those at a bunch of sites at my last job."

It's designed for reliability and comes with a variety of backup strategies in case of network failure. Historically, this included "dial out on alarm", but now can include wireless-modem options.

More than anything, NetGuardians utilize a variety of design and manufacturing techniques to minimize the chance of any failure. This includes brutal in-house diagnostic testing of each new device and EMI-aware design that places grounding precisely where it's needed on the in-house PCB designs.

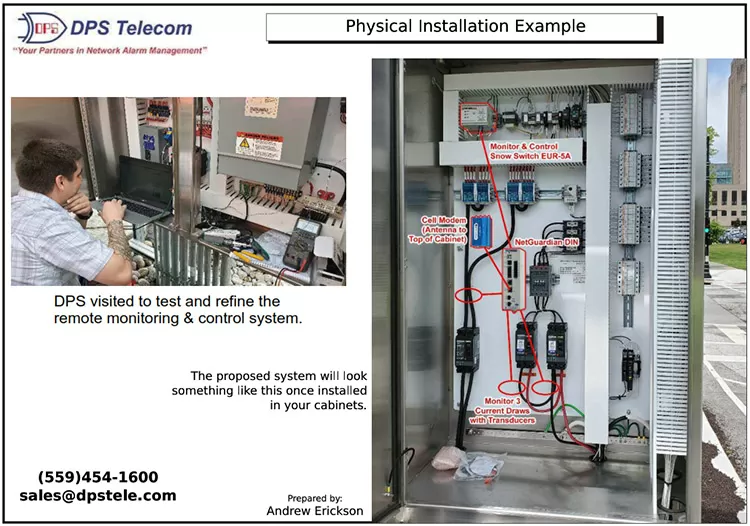

"Fit" is a choice you get to make with NetGuardian RTUs. For most cell sites, you'll have the required 1 RU (rack unit) of rack space available on a 19" rack (or 23" rack with the included longer rack ears). If you have a cabinet and need a DIN rail mounting style, there's the NetGuardian DIN. Small RTUs like the NetGuardian LT can mount either in a rack or on the wall.

With engineering and manufacturing both housed in California, USA, NetGuardians are not the absolutely cheapest devices available. You can find prices below $1000 and upwards of $5000, depending on the model and options you select.

That said, we're hardly talking about numbers that break the bank. A quality RTU can literally save hundreds of thousands of dollars during a prevented incident. It's amazing how many times my clients refer to RTUs as "rounding error" in a multi-million-dollar infrastructure project.

An RTU is a durable good. You shouldn't need to buy a new one for at least another decade.

Sadly, I do have people contacting me often to replace RTUs that just aren't doing the job. They didn't do enough homework during the initial purchase, and now they're hoping a NetGuardian will do a better job. I'm hoping they have enough budget left after making a costly buying mistake.

Don't let this happen to you. Relative to the massive headache of buying and installing the wrong gear, only to find out that you didn't do enough pre-purchase research.

Monitoring cell tower sites is essential for ensuring service reliability and protecting your investment in equipment and personnel. By carefully selecting an RTU that meets your criteria for compatibility, durability, security, reliability and cost-effectiveness, you can be sure you are making the best decision for your business.

The best way to accomplish that is to speak with an expert as soon as possible. After you conversation, all of the web-based research that you do will make more sense in less time. Get answers to your questions, get a clearer picture of the different solutions available, and make a decision that you be 100% confident about.

The better informed you are before beginning a cell site monitoring project, the more likely it is that you will end up with an RTU (NetGuardian or otherwise) that meets all of your needs. Don't take chances with your cell site monitoring - take the time to speak with an expert. You'll be glad you did.

Call DPS at any time at 1-800-693-0351 or send a quick email to sales@dpstele.com to speak with an engineer.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...