Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYour backup battery may represent the difference between the uptime of your network and costly downtime. That's why many companies spend thousands of dollars with the purchase of batteries.

With the health of your network on the line, protecting your batteries is critical. High temperatures are the biggest threat to your batteries - not only internal temperatures but the environmental temperature as well.

Because of that, having a monitoring system that can keep an eye on the temperature inside your batteries is critical in order to get the most out of them.

Many studies have shown that high temperatures compromise the performance and lifespan of batteries. In fact, for each 8C rise in temperature, a sealed lead acid battery loses half of its lifespan. And, once the heat has damaged your battery, its capacity can't return to normal.

As I've said previously, issues due to high temperatures don't only happen internally, but also externally. So, if a battery's temperature is higher than the temperature of the environment where it's located, it can lose heat due to conduction, convection, and radiation. On the other hand, if the environment's temperature is higher than the internal temperature of your battery, it will get hotter.

Also, faults in a battery and it's attached circuits can negatively impact its temperature. Common faults that can cause high temperatures are:

Battery temperature monitoring can detect these faults and alert you in a timely manner before problems escalate.

If the battery temperature is not monitored and properly regulated, permanent damage can happen. At best, some mechanical distortion or change in the chemical composition will occur - leading to an expensive battery replacement. But, in the worst-case scenario, the battery cell can rupture, explode, leak chemicals, or even cause a fire.

Simply speaking, batteries store energy. They contain chemicals, and the current is what results from the reactions happening between those chemicals.

Just like many other chemical reactions, as temperature increases so do the speed of the reaction. This can improve battery performance but to a point. If the temperature becomes too high, the chemicals can be permanently damaged, shortening the lifespan of your battery.

At colder temperatures, the battery chemical reactions slow down. The internal resistance of the battery increases, and it's capacity to produce high current on-demand decreases. This is one of the reasons why, on cold days, car batteries may have problems trying to produce enough current to effectively crank the engine. At extremely low temperatures, the chemicals may even freeze, and your batteries will stop working completely.

In a nutshell, both sides of the temperature spectrum (either too hot and too cold) can cause problems to your batteries. So, it's critical to constantly monitor the health of your batteries and make sure the temperatures are between both your low and high thresholds.

A simple, but outdated way to keep an eye on your battery's temperature is having someone manually checking on the battery string once or twice a week. An IR temperature gun can do this, and you can record the data in a spreadsheet.

If manually recording the temperature of your batteries, remember that you are looking for not more than a 3 degrees Celsius of difference between the battery and the ambient temperature.

Although this might seem like a simple way to monitor your battery's health, this process has many disadvantages. Some of them are:

Nowadays it is way more efficient to deploy a permanent 24/7 battery temperature monitoring system.

The most basic system involves a temperature sensor installed on the negative end of your battery, this way you'll have real-time temperature readings. Also, if you add an ambient temperature sensor, your monitoring system can also give you visibility over this variant. In fact, the most advanced battery monitoring systems can monitor aspects such as cell temperatures, charge current, voltage, and load current and voltage.

In a battery monitoring system, sensors are attached to each of the batteries. The sensor can measure things like internal temperature, individual battery cell voltage, and current. These data are transferred to your remote terminal unit (RTU).

The RTU will translate data into readable performance data and store your network information. It will also alert you and your team with alarm notifications via email, text messages, or even phone calls.

RTUs can also produce trend analysis reports. They allow you to access battery measurement information and historical data quickly and easily for trending analysis, which can be viewed on your PC and even downloaded.

Identifying issues, performing predictive analysis, and generating simple and clear reports is easy with an efficient battery monitoring software.

There are many elements that a battery monitoring system should have in order to provide you actionable information about your network. But, what constitutes competent remote monitoring is:

Downtime caused by battery failures can cause significant financial losses, damage to companies' reputations, and disruption of operations. You know how important it is to keep your network up and running, but do you know how often your batteries let you down?

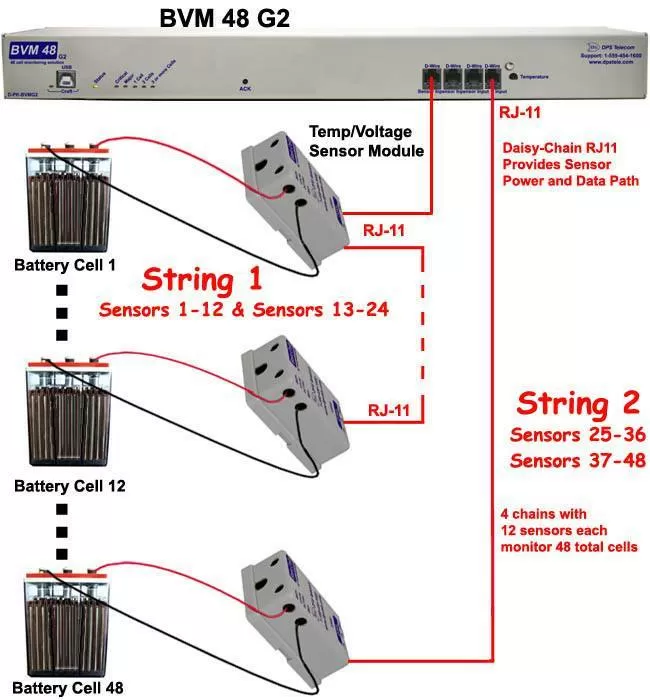

As a trusted remote monitoring solutions manufacturer, we know that being able to keep an eye on your battery health can be the difference between network uptime and costly downtime. Thinking about that we've designed an efficient battery monitoring solution - the Battery System Monitor (BVM) 48 G2.

The BVM 48 G2 monitors up to 48 cells and reports voltage and temperature thresholds alarms via SNMP. It also sends immediate alerts when a battery cell and/or string fall out of its normal range by more than a set percentage. When your SNMP manager issues periodic Get requests against specific cells, the BVM will offer both instant readings and trending to track battery voltages over time.

You can pair the BVM up with the NetGuardian 832A or 864A, this way the BVM's threshold alarms are passed through as local NetGuardian analogs. This type of system gives you the advantage of reporting alarms from the same IP address as the NetGuardian RTU.

If you so prefer, the BVM is also a great standalone, battery-monitoring solution.

Add one D-Wire sensor module for each battery cell to be monitored. The modules connect via daisy-chain to the front-panel of the BVM 48. Each of these modules measures both battery cell voltage and temperature. Daisy-chain up to 12 sensors from each of the BVM's 4 front-panel D-Wire ports (48 sensors total).

And keep in mind that our D-Wire sensors require no external power. All required sensor power is drawn directly from the BVM 48 over standard RJ11 cables. D-Wires are automatically recognized and configured by the BVM, and readings can be immediately viewed in the BVM's web interface.

Unfortunately, there's no magic crystal ball or something similar to correctly predict battery failure. Yet deploying a battery temperature monitoring system is the next best thing - and the optimal safeguard of your batteries.

DPS monitoring solutions are capable of keep track of a wide array of variables, including the temperature of each cell, ambient temperature, voltage, and current. The real-time data and ongoing analytics that you'll be provided can reveal subtle changes that allow you to predict battery failure.

With advance warning that your batteries will fail, you can correct the situation before the issue evolves to network downtime.

Still unsure if a battery temperature monitoring will make sense for your organization? Don't forget we can customize our solutions to fit your needs, just sends us a message and tell us what you need.

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.