Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayLet's walk through the reasons for high-quality battery monitoring. We'll look at the the inherent difficulties. We'll also review one possible solution that walks the line between "ineffective" and "too expensive to justify".

UPS batteries for telecommunications systems are used in many industries:

In their own ways, each of these industries protect human lives. That makes every remote site they use in telecom applications absolutely critical.

UPS battery strings are used as a backup power source to keep telecommunications equipment online at all times. This protects you when commercial power fails. That makes them just as deserving of protection as the communications equipment they power.

You need good remote visibility of your batteries to protect against:

Unfortunately, monitoring your batteries isn't always easy. There are plenty of optons that won't do the job, for one reason or another.

Scheduling recurring visits with a handheld tester is a waste of time and money. Your skilled technicians have much better things they could be doing. They shouldn't be driving for hours just to check on remote site UPS batteries. This also can't protect you from sudden failures (full discharge, thermal runaway) at sites you don't visit extremely often.

Buying expensive monitoring systems that are impossible to justify will never work. I've heard from many DPS clients a common (entirely serious) comment.

"For the price of most battery monitoring systems, I'll just replace the battery strings more often," they say. Perhaps that's an overreaction, but there's no doubt that budget constraints are real.

What you can never forget, though, is that the people you serve need your services to be 100% reliable. Replacing batteries is hardly the only cost of a service outage.

For that reason, not monitoring at all and having to replace your batteries will not work. Even if that's the "right" choice in the face of ultra-expensive monitoring systems, it's still wrong. With equipment failures, you have to price in the risk and impact of service outages.

You won't just be replacing a battery string. You have to contend with upset (and possibly lost) customers. If you work in "government" or telecom, the lives of your "customers" (residents) might actually depend on your network reliability.

So, what DOES work for keeping track of your battery status? The right solution will help you solve the problems above without dooming you to the pitfalls above.

These are the considerations I had in mind when I helped the Engineering team here at DPS. We revised our BVM ("Battery Voltage Monitor") system into the G3 model.

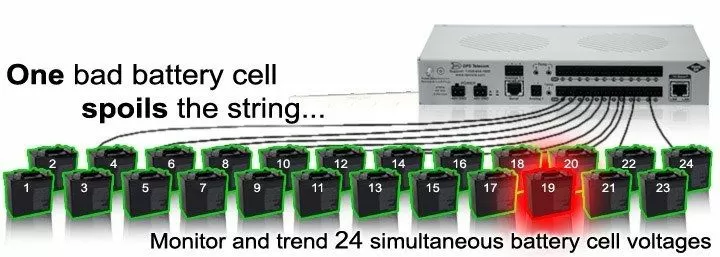

The birth of the BVM was, as the name implies, focused around voltage only. The device had 24 analog inputs for monitoring up to 24 cells. You simply wired leads to each battery in the string. That was great, but what about thermal runaway?

The BVM G2 incorporated temperature monitoring and our newer "D-Wire" sensor technology to support daisy chaining. You'd place one on each battery to get BOTH voltage and temperature readings. The gear is also 100% DPS-manufactured, giving us more control over quality.

This was a big improvement, but the D-Wire bus had limited power for running a lot of sensors. This was fine for 4-battery strings, but 24 batteries became unworkable. Also, the temperature sensor, being in the aluminum sensor chassis, had some moderate lag in detecting temperature spikes.

In 2020, I helped DPS Engineering to create a new BVM model. It would address "really serious battery monitoring", which encompasses long-term battery health. You can't simply detect this with voltage and temperature. You need more.

Like any good successor, the BVM G3 added a new measurement: internal resistance.

It sends brief pulses of AC through a battery every few minutes (or even hours). You get an updated reading of how much power is lost to internal resistance. This tells you whether you have internal cells that are starting to fail and short.

You have to determine which battery management device you want to purchase and implement in your network. I've given you a general outline of criteria you can apply when talking to any manufacturer or vendor.

DPS engineers and I designed the BVM G3 to be well-suited to real-world concerns you're likely to face. Only you can make the call.

If you'd like to evaluate a BVM G3 or other monitoring devices, set up a demo with us! Give us a call (559-454-1600) or email DPS: sales@dpstele.com.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...