Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayEvery SCADA system (or other "remote monitoring and control system") necessary involves some number of remote input and output devices. They're tasked with collecting data and issuing control outputs (ex. relay control) in response to a changing environment.

Because you're responsible for building and maintaining this system, it's up to you to select and configure the right equipment. As you may already know as you read this, your choices dramatically impact just how difficult that "configuration" is.

Let's start by reviewing the danger of choosing devices that don't integrate well with your organization's collective skills, then look at alternatives that are much easier to set up.

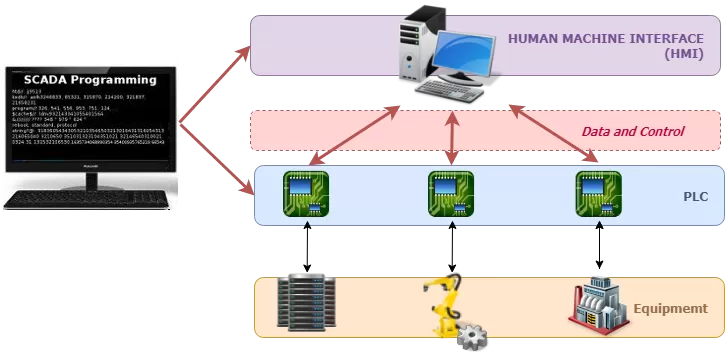

If you choose a system built primarily on Programmable Logic Controllers (PLCs), there's going to be some amount of programming involved. This can include ladder logic (based from a ladder diagram you'll also have to create) and the creation of customized input and output modules.

This is fine if you have capable and skilled technical people on your team. You can also hire consultants to create bespoke code for you, but that's an added expense.

Truthfully, in a process control or motion control SCADA environment, this might be your best and only choice. So much of those industries is built on custom programming of PLCs. Human-Machine Interfaces (HMIs) that form the core of the system, from popular manufacturers like Allen Bradley, actively expect that class of remote units.

You simply want to be careful if you're in a more generic monitoring situation (ex. small farm operation with simple temperature alerting) or in a telecom network that's spread across a large area.

In those environments, the value of PLC systems collapses quite a bit. Alternatives that arrive pre-programmed can be superior. Instead of programming software or programming device modules, you'll be able to do other valuable work.

Imagine a better option for a moment. Instead of an extended process where you connect the PLC to your network, then program it yourself, you have a much easier time.

You'll power up an RTU and put it on your IP network. You'll connect to an easy web interface, one that's not much more complicated than a typical wi-fi router.

You won't have to write code. You'll name alarm inputs. You'll name analog inputs. You'll set up available functions like if-then logic (similar to ladder logic in concept) and qualification timers (to prevent nuisance alarms).

Choosing a good RTU product line empowers you to focus less on monitoring and more on revenue-generating and cost-reduction operations.

Very quickly, you'll be monitoring your remote power supply, generator fuel, HVAC status, and more.

If the logic above makes sense to you, then you understand why I (via the rest of the team here at DPS) have established the NetGuardian product line of RTUs.

There are many different NetGuardians with widely varied capacity, transport methods, and mounting styles. All of them share one thing: you don't need to program them in the way that you program PLCs.

As I noted above, there are some situations where NetGuardians aren't the right choice. If you have a SCADA requirement for a typical complex manufacturing system, you might very well need typical PLCs.

If you're in manufacturing but you're trying to do something unique, like making two incompatible systems talk to one another, you might find that NetGuardians play a role.

If you have a telecom network, whether you work for a telco, power utility, railroad, or government, NetGuardians were designed with exactly this application in mind.

You'll be able to monitor your site's commercial power, rectifier output, backup generator, HVAC, and equipment alarms. You won't have to do more than wire everything up and name the inputs. If you need to set up some advanced logic, that's available in the same web interface menus.

Following the theme above, consider that you also don't want to get stuck programming your central HMI if you don't need to.

Yes, there are some "vanilla" SCADA environments where that's simply necessary. You might need to hire a consultant after you buy the HMI.

If you're working on monitoring for telecommunications, you might find instead that a different type of HMI is a better choice.

Imagine a menu-driven HMI where a wide range of common device types are pre-programmed as "device modules". You'll just choose the right module, specify the device's IP address, then configure any available custom I/O on that device. Any standardized device alarms won't require any configuration at all.

T/Mon is precisely this type of HMI. It supports many different protocols and common device types, from generators to HVAC to rectifiers, radios, and more.

No matter how simple a device is to set up and use, you're likely to get stuck at least once or twice during the turn-up process. That's where good tech support comes in. It can save you hundreds or thousands of dollars worth of wasted staff time.

That said, you shouldn't be paying exorbitant fees for support, especially if that support is rarely available and difficult to understand.

For these reasons, DPS support is based at our headquarters in California. If your in the eastern US, we get in fairly early (7AM) so you can get routine support without waiting until after lunch. Emergency tech support is available 24 hours a day, 365 days a year.

Tech support from headquarters is one thing, but consider that we also don't maintain a separate tech support group. When you call in, you're connected with actual product engineers. It could literally be the person who programmed the firmware you're using.

This means you'll get great support, but it also means that our product engineers constantly get feedback. If a reocurring pattern emerges, we fix it by adjusting the product's code or menu structure.

No matter what you think about the concepts I've articulated here, give me a call to continue our discussion. Even if I can't help you with NetGuardians or a T/Mon, I'll point you in the right direction.

I'll listen to the problem you're trying to solve, then match that with a product that will do the job. If DPS doesn't have a good fit, I can use my broader knowledge of the industry to recommend something else.

To get started now, just give me a call at 559-454-1600 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...