Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

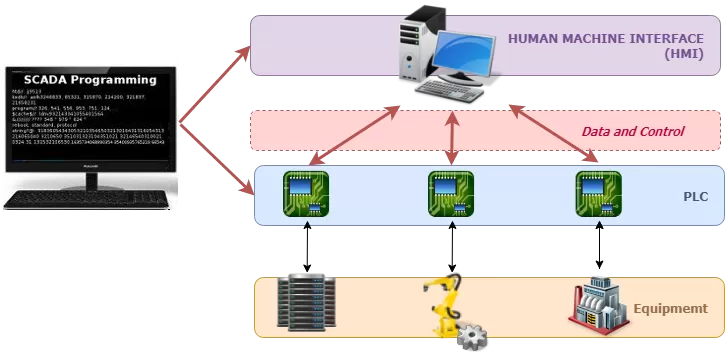

Reserve Your Seat TodayA SCADA operating system is the main set of software on a device that handles all the system's processes. The operating system talks with the device's hardware and provides services that applications can use. This means that SCADA operating systems manage input and output devices. Without an operating system, your SCADA system would be useless. In particular, a PLC controller relies heavily on an effective SCADA operating system to properly manage its automated processes.

PLC's are a type of Supervisory Control and Data Acquisition (SCADA) device. They monitor, automate, and provide a human interface for electronic control of processes. They take what would be a complicated mechanical process and provide the info and interface to make it an electronic one. The role of a PLC controller in this setup is critical for ensuring precise execution of automation commands.

PLC (Programmable Logic Controller) is a small digital computer used for automating and controlling electromechanical processes, such as control of factory product lines. They're made with a lot of input and outputs in mind. They are built to handle vast temperatures, electrical noise, and vibration common in industrial processes.

To provide this high level of process control, a PLCs gathers data through a series of discrete and analog sensors. It then either acts on the data in instances where it's been programmed to take action, or provides its user with relevant real-time data so he or she can take action. And because they're software-controlled, PLC systems are adaptable and allow for fast, relatively low-cost reorder of processes. This adaptability makes PLC controllers an indispensable part of dynamic industrial settings.

These examples illustrate the PLC's ability to manage and control complex systems. By integrating these specific tasks, the PLC controller seamlessly bridges the gap between data input and mechanical output, ensuring efficiency and reliability in industrial settings.

Prior to the invention of PLCs, automating the same processes required hard-wired relays, cam timers, and drum sequencers. Any change in the process required a costly delay while relays were rewired and other gear was fully calibrated. PLCs were invented as an electronic way to skirt these issues, allowing for faster software calibration of processes.

Due to high initial costs of install, PLCs are used in specific cased. For example, those processes where the requirements for automation are complex and subject to change. Also, where the output justifies the cost.

In recent years many smaller industries have tried to get cut the high cost of PLC install. They also tried still satisfying their desire for automation by using programmable logic relays, or PLRs. PLRs are much like PLCs, but with fewer inputs and outputs and are primarily used in light industries with fewer processes to automate.

However, while PLRs provide high-level algorithmic control for automation, they often aren't scalable. Additionally, they provide many sensors for info reporting. That's why some businesses are now opting to utilize Remote Telemetry Units, or RTUs as a PLC replacement.

RTUs are small-scale, PLC-like devices. They are equipped with a large number of discrete and analog sensors. They can monitor processes and control relays to execute basic controls.

RTUs like the NetGuardian series have proven to be a low-cost solution for monitoring actions, good for network, communications, and transport processes. They provide alarms to alert techs to problems, and take action to minimize any impact.

PLCs and PLRs often operate in proprietary protocols. However, many of them aren't compatible across platforms. They require special training to know and operate.

RTUs from DPS come with their own easy to read graphical interface and most likely output in SNMP. They even report monitoring info from legacy or proprietary devices, so long as they output ASCII.

The NetGuardian series can also output plain-text alerts. They can report the status of controlled processes remotely, to technicians' e-mail, or cell phone. Your technicians don't have to be specially trained or waste man-hours sitting in a control booth.

The NetGuardian 16 series RTUs even offer voice alerts right to your phone. If something were to go wrong with your process or other SCADA devices, you'd get a voice alert detailing the problem without having to wait for a call from a remote master. RTUs help you stay on top of your most important processes, so when something goes wrong, you can take action immediately.

RTUs are a cost-effective option in place of PLCs and PLRs providing a similar level of info and automation at remote sites. They are used for networking, communications, and transport processes.

An RTU, compared to a SCADA PLC, is generally more rugged and has higher monitoring and control capacities than a PLC. This makes SCADA RTUs superior at locations where many items must be monitored and controlled. If you have more locations that require just a few monitor/control nodes, then PLCs will probably be best for you.

For the above reasons, PLCs are commonly found in manufacturing and processing settings. Because plant operations can vary so widely, the customization of PLCs is a useful tool.

Nonetheless, RTUs have their place protecting the IT assets of a facility. In the server room of a manufacturing facility, for example, the monitoring and control needs are exactly the same as those in the server room of a major office building. RTUs are better suited for this sort of environment.

Although PLC customization offers advantages for veteran users, others may prefer to order an RTU custom-designed for their monitoring and control situation. The real trick here is identifying a manufacturer with the necessary facilities and experience to help you. Look for a company that has engineering and manufacturing inside of its organization. The last thing you want to do in the deployment of your important SCADA system is to wait for overseas development and manufacturing to be delivered, where quality also becomes a concern.

It doesn't matter if you decide to go with a PLC or an RTU, be positive that you know what you're purchasing and that the system covers all your needs. For this reason, always make sure to discuss your options with your potential vendor.

Don't compromise when it comes to your SCADA system. If you'd like to discuss more about RTUs and remote monitoring with me or with my team, we'd be glad to get in touch with you. Just contact us and we can get your perfect-fit solution started.

Are you researching the best practices for remote monitoring at your sites? Or are you working toward migrating legacy gear? No matter what, if you're considering the purchase of DNP3 equipment, it's important to...

by Andrew Erickson on May 10, 2019

If you want to start the process of implementing a remote monitoring or SCADA system in your network, then you're probably wondering if you should use an RTU or a PLC. You might be more inclined to choose an RTU if you...

by Andrew Erickson on April 26, 2019