Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayRemote temperature monitoring is most commonly used in telecom or IT environments where computer equipment must run reliably for years on end. It provides an extra measure of protection against thermal shutdown, irreparable and expensive equipment damage, and the lost revenue that results when systems fail.

As service networks have gotten larger and larger, the economy has made maintenance and management crews get smaller and smaller. Now, all around the world, we have a telecom and IT environment where maintenance teams can't hope to keep up without automated monitoring systems.

When you really think about the multiple ways that temperature can get out of control at your remote sites, it's obvious why heat-related threats get a lot of attention.

Your HVAC system could fail, causing server-generated heat to begin climbing immediately. Hot summer weather could make your cooling system simply inadequate. An electrical fire could break out, creating an instant temperature threat even for equipment that doesn't actually get burned. This is what makes remote temperature monitoring so important.

Fortunately, site temperature is actually one of the easiest things to monitor remotely. Unlike direct hardware monitoring of alarms, there are no protocols to worry about. You don't have to wonder whether your equipment has necessary alarm outputs.

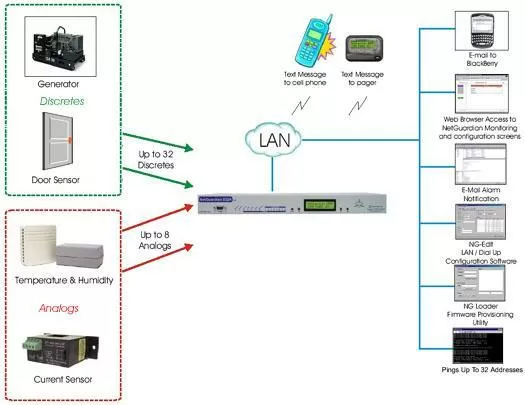

All you need is one or more temperature sensors to monitor remote site temperature and an alarm remote to send those reading back to you. You can receive temperature alerts either on a central alarm master console (if you have a big enough network to require one) or directly to you by email alerts, cell phone notifications, etc (if you have a small size network).

You should always be careful to choose a temperature sensor that can be powered directly by your alarm remote. This avoids the need to have a separate power transformer and power supply for such a small sensor (transformer bricks to produce industry-standard +12 VDC sensor power are almost always bigger than the temperature sensors they power).

You can provide direct power to your temperature sensors in two different ways. One way is to use "D-wire" sensors that are powered over the same wire they use to communicate. These remote temperature monitoring sensors have the added advantage of being "daisy-chainable" to support more sensors connected to a limited number of ports (even a single port) on your alarm remote.

The other way to directly power your temperature sensors is to deploy an alarm remote that has a built in +12 VDC power supply for external sensors. The NetGuardian 832A is one of just a few industry alarm remotes to include this power feed.

Since we're on the topic of choosing an alarm remote, you should also know that it's a good idea to pick one with historical storage of temperature values.

A remote like the (appropriately named) TempDefender IT can actually present a graph of temperature data across time. Although this is a function normally associated with a central alarm master station, it's not required because the TempDefender includes a web interface that will display charts and graphs of temperature over time.

Any computer on the network can access the web interface via any web browser by entering the device's IP address into the address bar. A username and password login prompt prevents unauthorized users from gaining access to your remote temperature monitoring system.

Charting temperature across time gives you insight into problems you may never have noticed otherwise. Moment-by-moment remote temperate readings are helpful, without a doubt. You'll gain a whole new level of network visibility, however, when you view temperature levels as a line graph that can display recurring cycles or steadily increasing threats.

This can help you to notice and respond to unseasonably warm temperatures. You could then respond by adjusting climate control, for example. You might also learn that your temperature has a large swing from the hottest part of the day to the coolest. This could lead to better utilization of the HVAC systems you already have.

Now that you understand a bit of remote temperature monitoring theory, I'd like to get a little more concrete by discussing a specific alarm remote and temperature sensor combination. The TempDefender IT and its D-Wire temperature sensors, which I introduced earlier, are good for this purpose. This equipment combination has become respected within the industry, owing mainly to its build quality (powder-coated aluminum instead of plastics used by some IT monitoring devices) and D-wire daisy-chainable sensor compatibility.

The TempDefender's web interface has also built it a better reputation than less reliable low-end remote temperature monitoring devices. The extensive interface is navigable with just a single list of links. Pages within the system are divided between "Edit" menus and "Monitor" menus. The monitoring side, which you'll use most frequently, includes base alarm inputs, system alarms (like "no LAN available" or "SNMP manager not found), control relays (for activating backup HVAC or generator systems remotely, etc.), and analog inputs (from D-wire and other analog sensors).

The editing pages allow you to configure the alarms and controls of the monitoring interface, but there are several other functions as well. You can set up the Ethernet configuration to allow web interface access and (optionally) reporting alarms to one or more SNMP managers. You can also configure email notification recipients and schedules (so emails are sent only after normal business hours when no one is in the NOC center, for example).

Timers are also configurable, allowing you to generate a virtual alarm when one alarm has been set for a long accumulation. This is handy for tracking your total generator run time since you last filled its fuel tank. After all, without fuel you can't generate backup power, and without backup power you can't run the HVAC if commercial power fails. Good remote temperature monitoring, it turns out, requires much more from you than simply tracking temperature sensor values.

Jim contacted DPS sales engineers with a need to monitor temperature at a desert-region telecom company. He needed to monitor 5 sites using alarms remotes, plus he had to collect alarms from 48 additional SNMP-native devices. Jim knew DPS equipment from a prior project he completed at a telephone company in a different region.

Each of the 5 sites needed temperature monitoring via a 7-foot temperature probe (powered directly by the alarm remote's dedicated jack). The ideal solution for this project was:

Another technician named Sharon called DPS for a large railway project. She had an engineer on the phone call to provide additional technical information about the project. He described the site as a telco shelter with a 19" rack and AC power. This was only remote temperature monitoring for a single site, but the site was a very important location.

The goal of Sharon's project was to provide remote site monitoring (including temperature) reported via SNMP to their large-scale SNMP manager. Sharon needed the ability to monitoring physical alarm points and report them via SNMP to her client's existing NMS (Network Management System). She needed equipment that would run in an AC environment and detect when power failed from the local utility or UPS system. She also need the ability to monitor ambient room temperature in real time.

The answer for this project turned out to be the NetGuardian 216. This alarm remote can monitor 16 discrete and 2 analog alarms, then report those alarms to any SNMP manager data logger. The NetGuardian has dual power feeds to monitor the site's power status and detect power failures from either the utility or UPS backup.

Sharon and her team were also looking to add some additional sensors, including temperature, humidity, water, and AC transformer - for added peace of mind.

Related Topics:

Remote Temperature Sensor

Network Temperature Sensor