Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

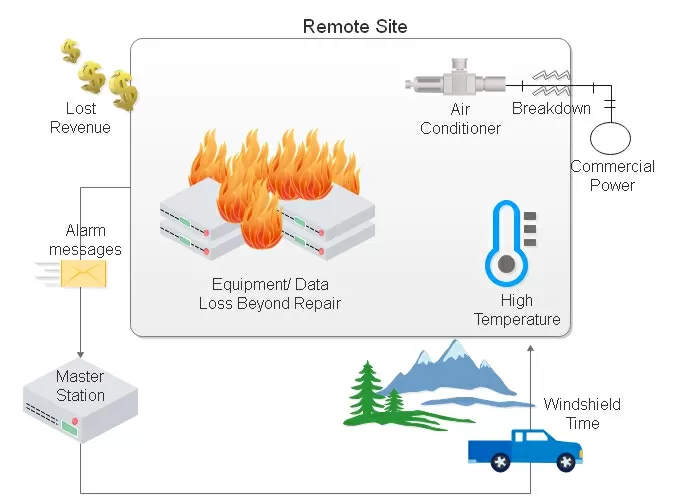

Reserve Your Seat TodayThermal runaway, and the resulting shutdowns and outages, represent a huge risk for you. You can't afford to have the temperature rise catastrophically or drop dangerously low without your knowledge.

That's where remote temperature monitors come in. When the temperature is rising, you need to know quickly.

In this article, we will talk about remote temperature monitors and how you can use them.

When the temperature rises too high or drops too low (although computer equipment deals well with cool climates, harsh winters with below zero weather will stop your network in its tracks) at your unmanned remote sites, your equipment is put at risk. If you have no idea that a problem is going on, there is no way that you will be able to fix the issues before it's too late and your network is compromised.

The solution? A simple yet reliable box that collects temperature data and sends you some kind of alert. This could be an email alert, a text message to your phone, or a specialized protocol message like an SNMP trap that gets sent to a dedicated "manager" server.

These boxes are called Remote Telemetry Units (RTUs). An RTU will collect the temperature readings provided by temperature and humidity sensors at your facility. Then, it will send this information back to you.

In other words, an RTU is a SCADA electronic microprocessor that monitors and controls equipment at remote sites.

Remote temperature monitoring systems tell you when your remote sites are overheating, and you can use them in a wide range of facilities:

There's almost no end to the applications I've encountered where people need remote temperature monitoring.

Sure, there are fairly typical telecom applications for monitoring the temperatures in a server room, power substation, or remote microwave hut.

But the variety doesn't end there. I've sold temperature monitors to deli counters and car washes (to prevent frozen pipes during the winter) and pig farmers (pigs are apparently quite sensitive to temperature). I've also had people monitor pipeline temperatures and install highly specialized nodes to monitor many aspects of UPS battery cells, including a temp reading for each.

No matter what reason or what environment you need to monitor, whether in degrees F or degrees C, there's a temperature monitor for that.

Independently what your industry and scenario are, there are some important capabilities that your temperature monitor should be able to provide you. Some of them are:

The first point you want to make sure your temperature monitoring system has is being able to track temperature in real-time across a continuous range. This means that, instead of only telling you if the temperature is above or below a predetermined value, it gives you the ability to check the precise temperature at any time.

This is only possible if you are using analog sensors.

With a user-friendly built-in web interface, you are able to log on to your device from anywhere on the network to edit your threshold configurations and check on the current status of your site. This feature allows you to get temperature information quickly - right from your PC.

Your RTU should be able to send you alerts to other locations if your company doesn't have a NOC operating 24x7. This means that, during after-hours, you can get email notifications, text messages, or voice alerts.

And during work hours, you can set your RTU to send protocol-based alerts (like via SNMP) directly to your master station. Your techs will then be able to assess the situation and deploy the right people to the remote site or simply take control actions accordingly.

Temperatures that fluctuate too high or too low can lead to equipment damage, network downtime, and power outages. Lack of monitoring or an incompetent system results in loss of visibility of your mission-critical equipment. So, by the time you find out what's going on, you may already have lost money due to gear damage and failure.

It's critical to know when your temperatures readings are getting close to your set thresholds, so you are able to fix any issues before they get worse.

Deploying a temperature monitor is an important monitoring best practice that guarantees peace of mind. Now that you know how they work, it's time to start protecting your network.

However, before anything else, it's important to make sure you are investing in a quality system. So, selecting a competent vendor is crucial. If you're starting your vendor search, give us a call. Our experts can answer any questions you might have and work to give you the perfect-fit temperature monitor for your needs.