Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayVertical farming is one of the biggest trends in agriculture in 2021. As Earth races toward a population of 8 billion people, maintaining adequate food production is an ever-growing concern.

What's more, consider the demands of people living in urban centers. People want "organic" produce. They push more and more for locally grown fruits and vegetables, are driving the farming industry in new directions.

How can you grow sufficient food to serve a large metropolitan area without going outside the radius that can be considered "local"?

Traditional farming, with flat plots of arable land, can't do the job beyond a certain level of density. There's just too little land and too many people to service with traditional farming methods.

This dynamic gave birth to indoor vertical farming technologies. Vertical farming is "Controlled Environment Agriculture" (CEA), where nothing is left to chance:

As wonderful as vertical farming might be, there are problems that you must address.

Consider that:

The answer to these problems is well known in other industries. Phone companies, internet providers, manufacturers, and wastewater treatment plants have dealt with them for decades.

Strangely, the push to artificially controlled farming techniques makes agriculture quite similar to telecom or manufacturing operations. You have a large area to monitor and limited staff. You need help from an automated detection and control system.

That means we can take a page from telecom & manufacturing playbooks to get better results for our vertical farm.

Many of the sensors and outputs we can use for monitoring farm operations can be pulled directly from telecom/manufacturing operations. Others can be tweaked slightly to deal with unique properties (especially moisture) present in farming:

Take a look at DPS line of D-Wire sensors for remote monitoring.

With a collection of sensors placed strategically throughout your vertical farm (or similar facility), you now need a nearby box that will pull the data together. Depending on the layout of your operation, one "Remote Terminal Unit" (RTU) can theoretically handle dozens of different sensors.

Choosing an RTU revolves around a few key factors, namely:

If you want to equip your vertical farm with an RTU that will keep up with your requirements, then look no further than the NetGuardian 832A G5. This RTU gives you 32 discrete alarm inputs, 8 analog inputs, and 8 control relays in one single box. The 832A G5 is sure to provide you with powerful features to make your job easier.

OK, so now you have data from sensors being collected by your RTUs. You have control outputs from that same RTUs to exert remote control over your systems. What next?

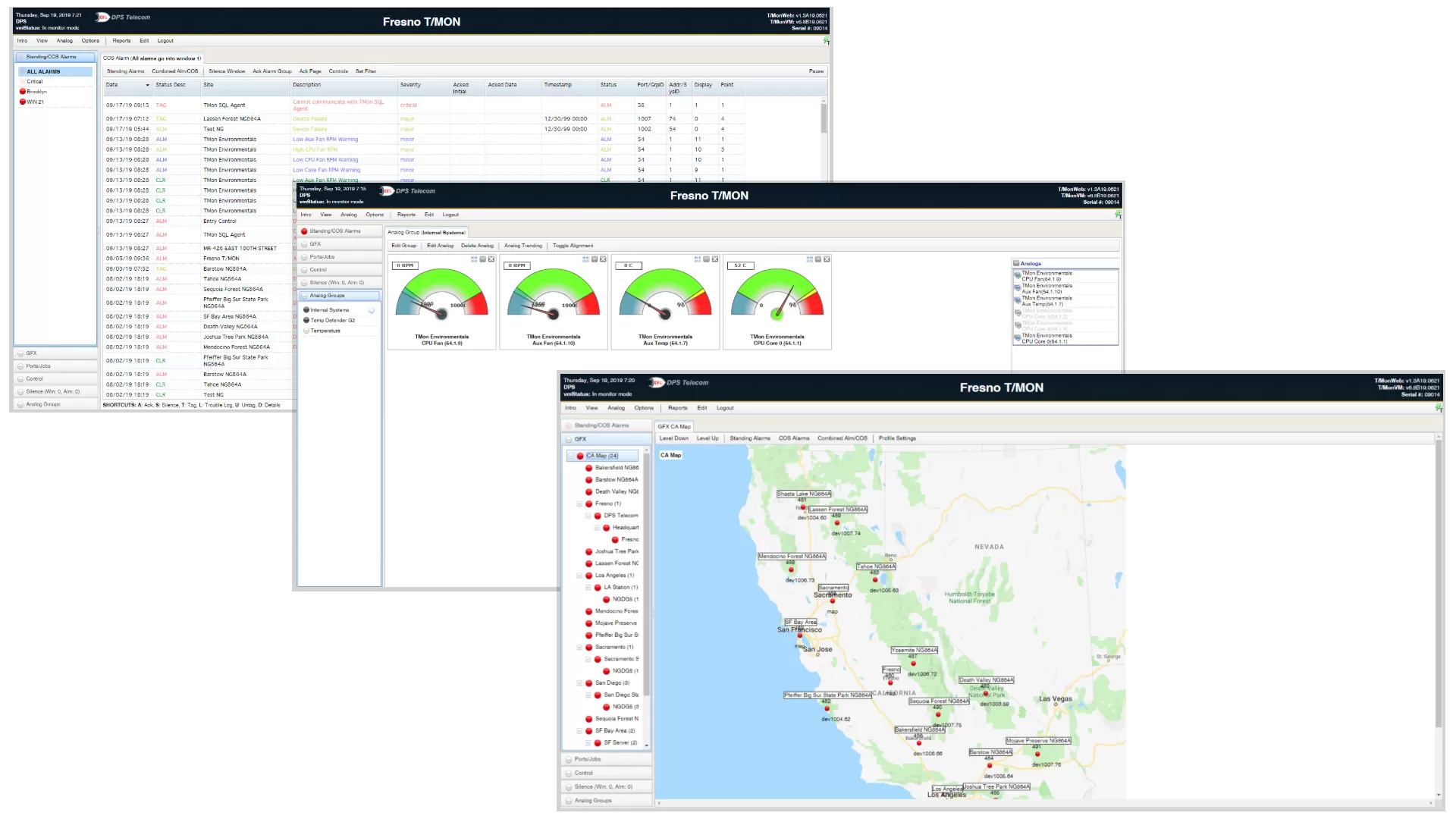

You now need to establish a central master/manager that oversees everything and displays real-time status for you. In SCADA terms, this is the main "Human-Machine Interface" (HMI).

Just like when planning your sensors and RTUs, compatibility is key. Whatever protocols your RTUs support (ex. DNP3, SNMP, MODBUS), your master must support all of them to create one cohesive system. That's the only way you can monitor and control everything without making your head spin - or hiring more people than you need.

The T/Mon is a multiprotocol master station that collects data from multiple different types of equipment, throughout many manufacturers and protocols. It also displays the state of your entire network in one intuitive interface, eliminating the need for specialized terminals. With T/Mon, compatibility will not be a problem for you anymore.

The end goal of any remote monitoring and control system is to detect and prevent issues that will ultimately impact your bottom line. Having efficient RTUs and master station will provide a more thorough understanding of the overall condition of your vertical farming technologies.

Reach out to us if you have questions on the details of vertical farming monitoring and control, and the types of monitoring devices that might work best for you.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...