Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you want to start the process of implementing a remote monitoring or SCADA system into your network, then you're probably wondering if you should use a Remote Telemetry Unit / Remote Terminal Unit (RTU) or a Programmable Logic Controller (PLC). You might be more inclined to choose an RTU, but before committing to anything, you need to know and understand the disadvantages of this approach.

Let's take a look at the principal points that differ RTUs from PLCs, the top three biggest problems with using RTUs get telemetry data, and some tips to help you choose the best device for your network.

A SCADA (Supervisory Control and Data Acquisition) system, at the machine level, consists of a central station for gathering data and managing the overall operation. It also has sensors - these could be RTUs or PLCs - placed near to where the action is. An RTU or a PLC will collect the data locally and then send it to the central station. This central station can be located several miles away.

RTUs and PLCs are naturally in opposition. While their primary purpose might be the same - to collect data and send it back to a master station - they go about it in different ways.

When compared to PLCs, RTUs are bigger, have more inputs and outputs, and have a lot of built-in intelligence. They don't require programming experience. All of these aspects might have you thinking that RTUs are a better monitoring solution than PLCs, but RTUs can also bring some downsides with them. Let's dive into the top three biggest problems with RTUs.

The first downside that an RTU box will have is less programming autonomy.

If you need a stand-alone controller with power for you application, a PLC is likely your best choice. However, be aware that some level of programming experience will be required for the device to be able to perform its monitoring role.

When you buy an RTU, you don't have to program it because it'll have embedded features that you simply configure. This is much like how you'd configure a managed switch or another network device.

Most of the RTUs being built today have a straightforward web interface - and that's awesome if you don't know how to program or don't want to spend your time programming. However, of course, it does limit your freedom. There's absolutely nothing like a blank screen that's just waiting for your custom code if you really want to do something that's just amazingly specific.

Now, you might be choosing to go with an RTU and looking to get similarly high levels of customization. If that's your case, then you really have to communicate with your manufacturer or vendor about the specific things that you're trying to accomplish. Tell them all about it, so you'll know that the RTU you're evaluating is going to give you the upside of speed without limiting you to some feature set that's never going to get the job done.

The real trick here is to find a manufacturer with the necessary facilities and experience to help you get a perfect-fit solution to your monitoring/SCADA problem.

There's really no way around it - RTUs are usually a bit larger than PLCs.

Imagine a 19-inch rack-mount device versus a small wall-mounted box that's maybe a third or half of that size. There are some smaller RTUs that approach the size of a PLC, but they usually tend to be bigger for an equivalent function.

This might not be a problem for you, and it certainly may sound like a silly decision point when you're dealing with the complexity of a remote monitoring or SCADA system. Keep in mind, though, that sometimes your space might be severely limited. You could be installing your gear in a small cabinet or maybe you're in a manufacturing environment, so you're already having to work around all of the other equipment that's already there.

As silly as it may seem, you might actually have an easier time learning a little bit of PLC programming rather than trying to magically create extra rack space out of nowhere to fit your RTU in there.

Now, let's take a look at the third and final problem with RTUs: they have a higher minimum price.

PLCs are usually manufactured at high volumes. You'd normally think of them as a commodity product. They're not usually programmed when you get them, so there's no programmers that had to be paid to write any code at all (that becomes your job). All of that, though, pushes the market price of a PLC to be pretty low.

When you look at RTUs, you have bigger size, more inputs and outputs, more built-in intelligence, so even the cheapest RTUs can't get quite as low in price as PLCs can. Of course, if you look at the total price of your purchase - from the install all the way through ownership and maintenance - that can be another matter entirely. However, that initial purchase price is generally what gets a lot of attention from your management, so it's something you need to consider.

If you do your homework, though, ordering an RTU for your SCADA system might become a cost-effective option.

Even though RTUs have these three disadvantages when compared to PLCs, they might not mean anything to you in particular. Maybe you don't want to program your monitoring device yourself, or maybe you don't have a problem when it comes to rack space, and you were allowed sufficient budget to purchase an RTU.

Your decision might come down to reliability, and the capabilities and functionality that you need. This means that the monitoring device you choose is perhaps most heavily related to your industry. There are no guarantees that a certain industry will be best served by an RTU or PLC, but this tendency exists because each industry has common structures and procedures.

PLCs are generally found to be quite useful in manufacturing environments, due to the following aspects:

Similar to PLCs, RTUs are commonly associated with their own set of industries. They're usually deployed into industrial telecom networks - used by all sorts of telecommunications companies, transportation companies, government entities and others as well. Again, there are many reasons why they prefer RTUs:

Have you read through the biggest disadvantages of RTUs and decided that those are not really problems when it comes to your scenario? Did you decide that purchasing an RTU is going to bring you more advantages in the long run?

If so, here are a few things to look for in a good SCADA RTU:

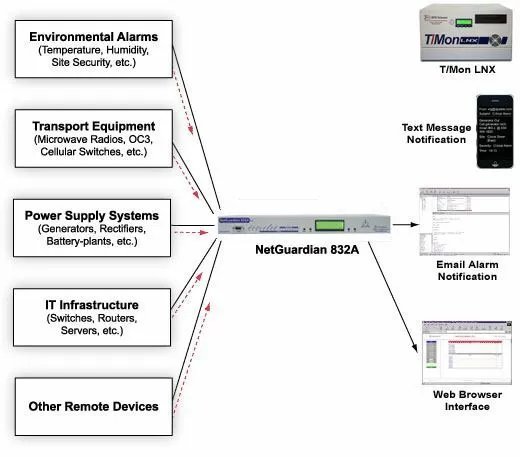

The RTUs from DPS are a good example of monitoring units that are competent and can be a cost-effective alternative to PLCs. These RTUs come with their own understandable graphical interface, and virtually all models output standard SNMP. They even report monitoring data from legacy or proprietary devices, as long as these devices output ASCII.

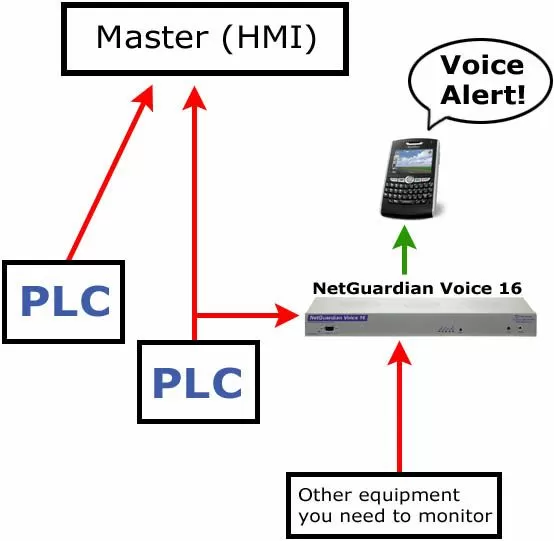

The NetGuardian series can also output plain-text alerts. They can report the status of controlled processes remotely. They can send alerts to you or to your techs through email or cell phone. Your technicians don't have to be specially trained and they don't have to waste time sitting in a control booth.

Some NetGuardians even offer voice alerts right to your phone. If something were to go wrong with your network or other SCADA devices, you'd get a voice alert detailing the problem without having to wait for a call from a dispatch center.

NetGuardians help you stay on top of your most important processes, so when something goes wrong you can do something about it immediately. Keep them in mind if you think that RTUs are the best monitoring devices for you.

It doesn't matter if you decide to go with a PLC or an RTU, be positive that you know what you're purchasing and that the system covers all your needs. For this reason, always make sure to discuss your options with your potential vendor.

Don't compromise when it comes to your SCADA system. If you'd like to discuss more about RTUs and remote monitoring with me or with my team, we'd be glad to get in touch with you. Just contact us and we can get your perfect-fit solution started.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...