Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodaySemi-custom work is routine at DPS, especially for medium or large projects involving Qty 11 or higher.

That applies to our RTUs, as well as to software customizations and Device Modules for supporting third-party equipment in our T/Mon master stations.

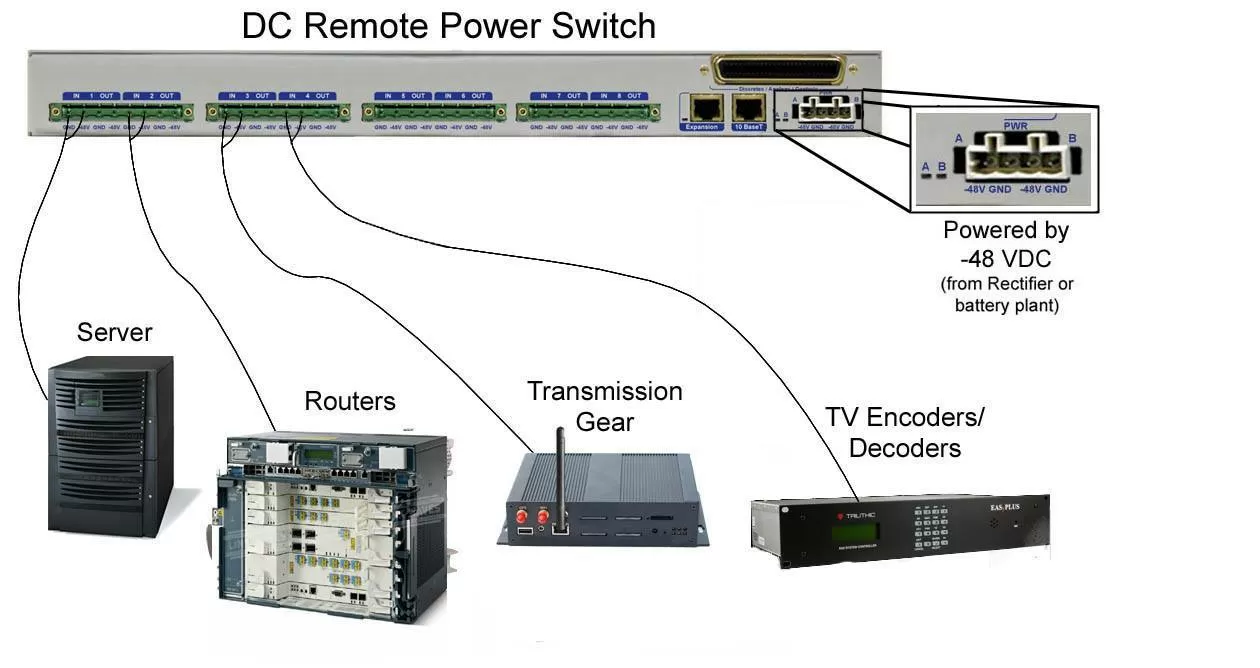

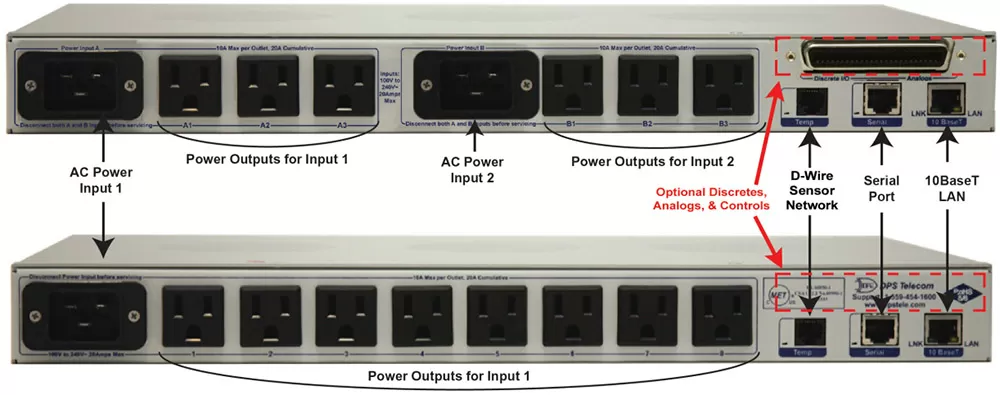

It also applies to supporting equipment like our PDUs (Power Distribution Units). If you need to toggle power to equipment, whether for remote on/off control or remote-reboot power cycling, PDUs are your answer.

Unfortunately, Power Distribution Units are never one-size-fits-all. You need to carefully plan so that you have the correct number of outputs, the right connectors & plugs, the right amp ratings for your planned current draw, the correct AC/DC voltages, and the right form factor.

To give you some tips on how to plan for your PDU project, and to provide a sneak peek at working with DPS, let's take a look at some work I'm actively doing with custom PDUs now:

This kicked off over the phone, then I arranged to stop by after a nearby install visit for a local fiber ISP. Power utilities have an advantage when seeking custom work, since high site counts generally mean minimum orders aren't a problem. Even so, remember that DPS generally only requires a minimum order of about Qty 11 for most custom orders.

Arriving at the large headquarters building, we met with 4 employees. The group included telecom engineers and telecom technicians, each of whom brought a different and important perspective.

When I'm designing equipment, I hate to leave out something that might save you time or money. Without senior management, I might miss some critical government requirement or time-saving reporting feature. Without installation technicians, I might design something that requires extra hassle to install.

In about two hours, I got an absolute treasure trove of information to design a perfect-fit PDU that mounts on a DIN rail.

- Single AC input, 15A max, breaker handle like the existing DPS Remote Power Switch AB6 would be nice to have. There was much debate about 40A input, or perhaps two 15A dual inputs, and/or twist-lock connectors for power. Ultimately, the requirement to go to a double gang box for any of those options was not preferred due to limited space "real estate issue" in cabinet. During the time we were entertaining dual inputs, we were thinking about dual internal DC-to-AC transformers. These would be divided into (AC+DC) 3+3 "critical half" and 3+3 "non-critical" half. These two sides would be powered by a 15A "critical" input and a 15A "non-critical" input, but this idea similarly had to be abandoned due to the single gang box restriction.

- Firmware to support user-customizable delay (probably just a few seconds) when powering up. This avoids power-on surges that might be nearly 5A each (a typical device fuse rating) and collectively trip the 15A breaker.

- Hard requirement for 4 DC and 3 AC devices, but they want 6+6 outputs (AC+DC) based on possible future growth.

- Cabinet Device List:

- Modem (AC)

- Site Controller (AC)

- DC 24V Switch (24VDC)

- Palo Alto (24VDC, non-critical: "we could run without it" for a while)

- Qty 2 of RV50 (AC or DC)

- Terminal server (This might be PoE? This device may also be replaced by this new DPS device if we also add a serial terminal server).

- Qty: About 30 sites, plus a few spares "to start with. If we standardize on this, it could be more later."

- 10A GMT fuses is enough per output. This avoids blowing if a 5A device momentarily pulls a bit more.

- Industrial temperature rating is a huge need. I confirmed with the team that I heard them correctly: 180-200 degrees F in cabinets. They confirmed that 104 F air temp + baking in sun can mean 180 degrees F. I discussed that our IT rating of 158 F is, like most DPS things, at least a bit conservative. We can test any prototype in our temp chamber.

- Alternate build: +24 VDC input with only DC outputs

- Alternate build: -48 VDC version with only DC outputs

- Ping alarms to trigger reboot, likely with some using Derived logic for multiple pings OR'd/AND'd together.

- Need magnetically latched relays, so there's no "offlining" (or even unexpecting "onlining") during DPS device power loss or reboot.

- Build option (may become their preferred standard): Serial terminal server to replace existing device, which has just two RS232 and two RS485. This has forced daisy-chain on RS485 to support more than 2 devices, which is less reliable. For DPS device, they want 4 ports that are ideally software-configurable for 232/485. If that's not possible, perhaps 3 of each type (6 total) would be nice.

I pitched our "preload at factory" options for configs/IPs, which was foremost in my mind after doing so for another client on this trip. As it turns out, they prefer receiving "vanilla" device defaults, largely because the legwork to plan unchanging IP assignments that far ahead is challenging.

They asked about training and install, so I discussed on-site and DPS Factory Training options.

Watch this blog for a virtual prototype, soon. I'm actively working on one for a review meeting in the next few days. At DPS, we find that a bit of clever Photoshopping helps everyone stay on the same page and anticipate problems before we even start manufacturing the real thing.

This one is a bit strange, but it actually makes sense when you think about it.

Here's the concept: Imagine that you work for a state government with thousands of roadside communications cabinets. Sometimes, less-than-stellar drivers veer off the road and strike your cabinets. Sometimes, the physical damage isn't catastrophic to the equipment, but electrical surges and grounding can cause irreparable damage.

The idea here is to have a PDU that can detect an impact (similar to a car airbag sensor), then very quickly cut power to all site devices.

- RE: Auto-power-cutoff when cabinet hit by car: Some cabinets have direct connection to the network. Maybe half are connected to cell modem or cable modem.

- 100-200A on main circuit breaker. We need to put a disconnect switch on the cabinet. The existing PDU (16 AC ports) could cut off power, but this might not be ideal.

- 30-60A are common ranges of main circuit breakers. "Commonly, we have 30A, 40A, or 60A in 60% of cabinets." (We'd need our quick-kill breaker to support >=60A)

- 2 RU would be fine in most cases for this new DPS device.

- Qty 20 for power-relay switch.

- Power-relay switch must be compatible with existing DPS TempDefender IT (G1). There are already Qty 16 in field.

- Client also interested in wireless sensor (back to TempDefender G1/G2) mounted on overpass that can detect a vehicle impact on support columns/structure. Bridges/overpasses might get hit due to low overpass, etc. Need some kind of seismic sensor that could detect a car impact on a large concrete/metal structure. Don't want to run conduit. Simple installation. Standalone with battery and wireless system, with maybe 2-year replacement window for battery. Reports back to existing DPS RTU. "If you have an option for that, I'd love that. "

- PDUs at site are 2 or 3 different brands, mostly EATON 2U EMAU05-10.

- Monitor Morningstar Solar Power Controller

- Monitor Leviton load sensor

We manage important systems at DPS, and one major subset of those systems relate to aviation navigation and safety.

- Another thing client might want (still being discussed) for the new DC PDU is dual ethernet connections. With the current DC PDU, there have been a few occasions where the output port that powers the router that provides connection to the PDU is mistakenly powered off. This renders the PDU unreachable, and the only way to get the site back up is to send a field tech to manually switch the PDU. This is very expensive if the site is very remote. With two ethernet connections, we can connect to each router. If one is down, the other still can talk to the PDU.

- We make DC PDU we call the Remote Power Switch AB6, which is a 1U, dual-DC-input to 2x6 DC outputs. This proposal will update the AB6 to use the newer G6 processing core, which provides newer security features that client needs in order to meet security standards.

- DPS would also alter it to use the Anderson PowerPole connectors, so that it could be an easy swap with their existing DC PDUs (and to avoid making new power cables).

- AC PDU might also be updated to the G6 core to replace our current AC PDUs used in many sites (and other locations).

- Next meeting will be to discuss this further with more client stakeholders and with DPS Engineering, particularly the security standards we would need to meet.

As you can see, there's almost no limit to the different PDUs that I can build for you. In many cases, I can just pull a design off the shelf. Other times, we'll build something new together, usually within 1-2 months (we work pretty fast).

What do you need your next PDU to do for you?

Call me at 559-454-1600 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...