Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA battery monitoring system is only as reliable as the quality of your actual installation and configuration/provisioning.

You can deploy the best sensors and RTUs on the market. However, if they're installed without a solid plan, accurate thresholds, or cybersecurity protections, your monitoring results will be incomplete at best (and dangerously misleading at worst).

At DPS, we've worked on thousands of telecom and utility deployments. The difference between long-term success and chronic false alarms almost always comes down to whether the team followed a structured install process.

This article gives you the eight best practices you need to get monitoring right - from the first cable run to long-term data retention and compliance. If you're rolling out - or considering - a new battery monitoring solution, this is the checklist to follow to get maximum uptime protection and a full return on your investment.

You've got good gear. Your setup will include an RTU, battery monitoring sensors, and a clear need for monitoring your remote battery strings.

So why do so many deployments go wrong?

There's a big difference between "installed" (which is sometimes just a "rubber stamp") and properly deployed.

We've audited sites where:

No one sets out to make these mistakes. But when crews are rushed or the site survey is skipped, bad habits creep in.

What's worse is these issues often won't cause an instant failure. Your system works... sort of. Until it doesn't. And by then, your batteries are damaged, your site goes dark, or maybe your compliance team is asking why last quarter's logs are missing.

Let's fix all of these problems before they begin.

Related Articles

Learn the benefits of monitoring your standby batteries, what you should keep an eye on, and the difference that a competent battery monitoring device can make for your network.

by Morgana Siggins on January 19, 2021

Battery health is critical for the reliability of remote telecommunications equipment. Your common challenge is making sure that battery monitoring devices can function effectively under difficult conditions. To do so...

by Andrew Erickson on June 10, 2024

Ensuring that backup power systems are operational and efficient is of the utmost importance. Neglecting to monitor battery health can lead to fines and downtime.

by Andrew Erickson on May 3, 2024

Imagine having a remote site where all of your monitoring just works.

This is the level of professionalism that backup power for telecom systems demands in 2025. And you can get there - with the right checklist...

Map before you mount. Before you order sensors, take the time to map every jar, string, and sensor location.

This is also the time to collect baseline impedance data. If you don't have a recent PM report, now's the time to generate one.

Realistic thresholds mean fewer false alarms and thus faster reactions when things go wrong.

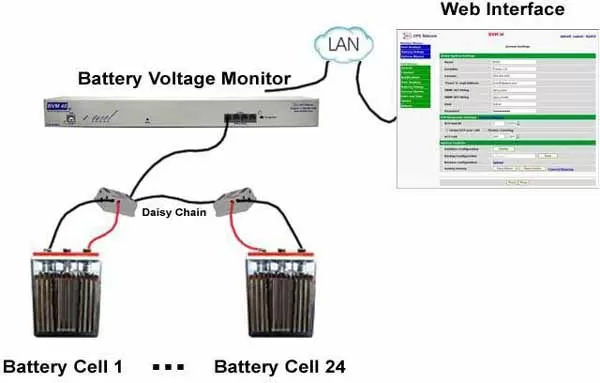

When it's time to install, follow this golden rule: inside to outside. Start at the most positive jar and daisy-chain your sensors toward ground.

This is an important step as doing the opposite creates step-potential loops. These loops introduce measurement noise and possible shock hazards.

Other important steps to follow include:

Generic thresholds are fine for demos. But real-world batteries degrade uniquely.

Start by customizing thresholds to match your site's baseline:

| Metric | Minor Threshold | Major Threshold |

|---|---|---|

| Voltage deviation | + or -3% of nominal | + or -5% of nominal |

| Internal resistance | +15% rise | +25% rise |

| Temperature | + or -5 C | + or -8 C or >45 C |

Be sure to review your thresholds quarterly. Ambient temperature swings can shift "normal" resistance by up to 10% seasonally - especially in outdoor cabinets or coastal areas.

Your battery monitor talks to the network. That means it should follow network-security best practices.

Here's what top-tier deployments do:

These practices are intentionally strict. CISA reports that SNMPv1/v2c remains a top attack vector for critical infrastructure. Don't let a $500 battery sensor open the door to a ransomware attack.

Monitoring is more than watching numbers. With the right data strategy, you can predict failures before they happen - and justify budget for timely replacements that ultimately reduce your spending.

For the best ROI:

Firmware isn't just about features - it's about security and survival.

This follows NIST 8259A best practices and aligns with DPS's proven update protocol (inspired by Siemens Industrial Edge procedures).

A failed update in a remote desert hut is more than a hassle - it's a needless truck roll that (annoying) probably has to happen immediately.

Even the best systems need a gut check to verify the quality of its functions.

You don't want to skip these steps. Many insurance providers now require verified alarm testing as part of their audit process.

Your techs are smart. But they're only as effective as their training.

Provide 4-6 hours of hands-on instruction covering:

It also helps to create a written SOP with instructions for sensor replacement, threshold adjustments, and bypass procedures.

This is why DPS even offers on-site training tailored to telecom crews to help ensure everyone's fluent in your monitoring setup - not just the person who installed it.

You can be confident in the success of your system if you have:

The next 10 years will bring new battery chemistries, stricter codes, and evolving threats. Luckily, DPS system is ready.

To prepare for what's ahead, DPS has engineered the G6 NetGuardian RTUs and BVM (Battery Voltage Monitor) sensors with these best practices in mind.

A G6 NetGuardian is not just a central brain for your monitoring network. It's a hardened, cybersecurity-ready hub that supports modern protocols like SNMPv3, TLS, and role-based access. Whether you're integrating with an NMS or segmenting traffic through a DMZ, the G6 NetGuardian adapts without compromise.

Meanwhile, BVM sensors offer high-precision internal-resistance, voltage, and temperature readings that support both legacy VRLA banks and emerging lithium chemistries. They daisy-chain cleanly and log history in customizable resolution.

When combined with onboard storage and real-time analytics from the G6 RTU, these sensors empower teams to spot early signs of sulfation, imbalance, or thermal drift - before they turn into outages or compliance failures.

From firmware management with rollback safety to training-friendly diagnostics, DPS helps make your field deployments durable, secure, and smart from day one.

Bottom line: You're not just buying a monitoring system. You're buying 10+ years of resilience, insight, and uptime (or failing to do so if you make the wrong choice).

DPS clients consistently report fewer false alarms, lower maintenance costs, and better compliance scores - all because they followed a structured install playbook.

Now it's your turn.

Let's talk about your next deployment. Whether you're retrofitting old strings, standardizing across regions, or deploying new tech, we're ready to help.

Call me directly at 559‑454‑1600, or email sales@dpstele.com

I'll walk you through your first steps - or review your existing plan and spot any gaps.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...