Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayFactory training helped a wireless ISP maximize RTU capabilities

| Field | Details |

|---|---|

| Industry | Wireless Broadband ISP |

| Company Type | Multi-State Carrier-Grade Provider |

| Geography/Coverage | Eight states across the U.S. |

| Primary Challenge | Technicians needed RTU operation training |

| Solution Deployed | Four-day factory training at DPS headquarters |

| Key Result | Mastered remote access and control capabilities |

| Implementation Timeframe | Four-day intensive program |

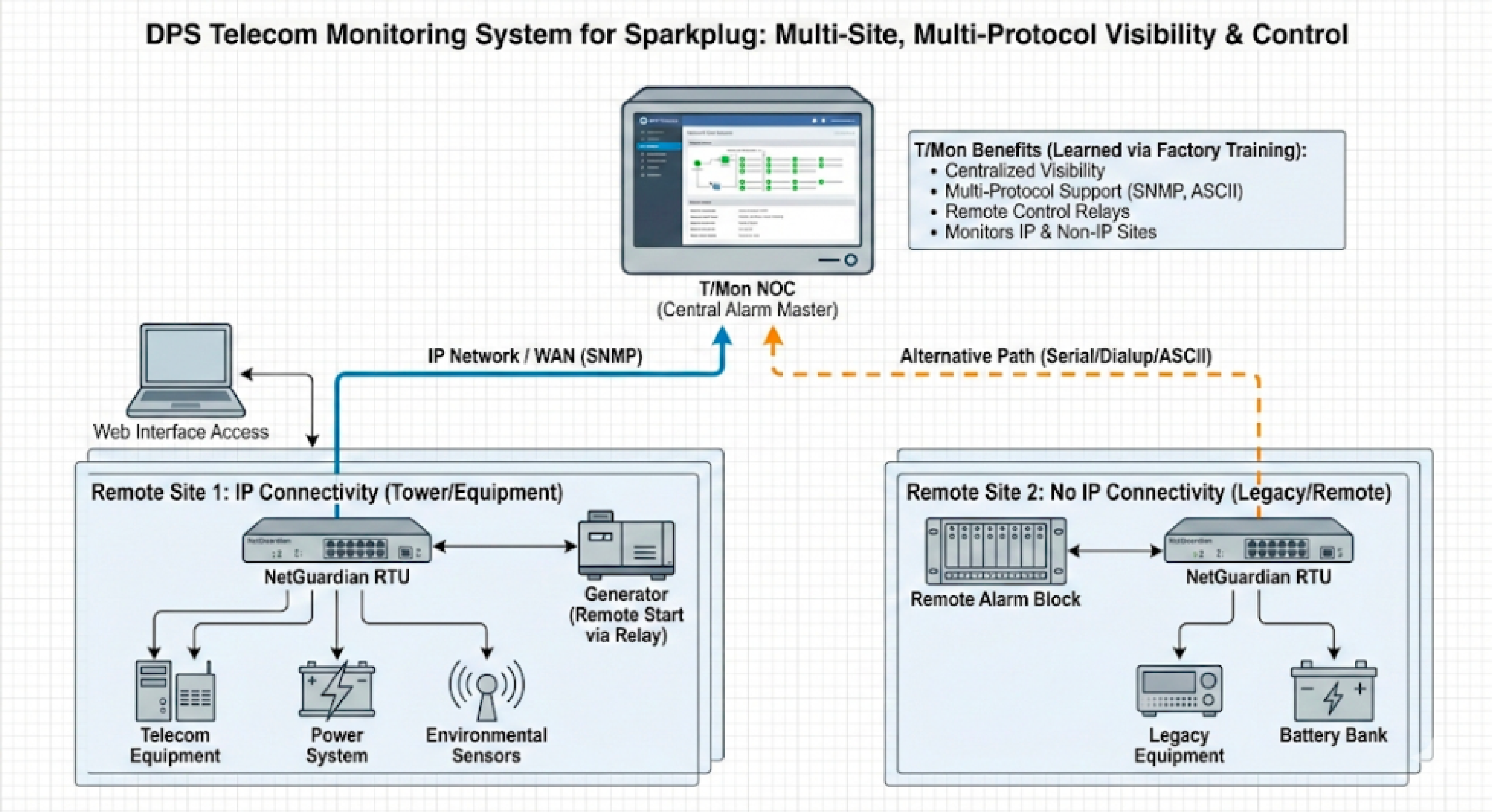

| Products Used | NetGuardian RTUs, Remote Alarm Blocks, T/Mon |

Sparkplug provides carrier-grade wireless broadband across eight states including Illinois, Arizona, Iowa, Tennessee, Nevada, New Mexico, Colorado and California. They deliver business broadband, transport services, and networking solutions to business, carrier, government and education customers in major metro areas. To maintain network reliability, Sparkplug deployed DPS Telecom monitoring equipment across their infrastructure.

Sparkplug relies on alarm monitoring to provide consistent service to clients. The company deployed a fleet of remote telemetry units to instantly alert technicians of transmission failures. Assistant Network Optimization Engineer Gilbert Clapp worked with these remotes at California and Arizona sites. He needed training to help Sparkplug technicians work more effectively in the field.

Specific training goals included:

Gilbert Clapp and O & M Field Technician Germaine Thompson attended four days of training at DPS Telecom headquarters in Fresno, California. DPS engineers taught visibility-maximizing techniques and hands-on operation of NetGuardian RTUs and Remote Alarm Blocks.

Training showed how T/Mon could monitor sites without IP connectivity. The control relay feature particularly impressed Clapp. If a generator fails to start during AC power loss, T/Mon can send a remote start command.

Training equipped the Sparkplug team with hands-on expertise they could apply immediately to their multi-state network. They learned how to access NetGuardian RTUs remotely through web interfaces and discovered new monitoring capabilities. The control relay functionality particularly impressed the team, as it enables remote generator starts during power failures.

| Oucome | What Sparkplug Gained |

|---|---|

| Remote Access Skills | Log into NetGuardian web interface via IP address |

| Enhanced Site Visibility | Monitor locations without IP using T/Mon |

| Equipment Control | Remotely start generators during power failures |

| Protocol Knowledge | Understanding of ASCII and SNMP communication |

Before training, Clapp had never learned what ASCII or SNMP protocols were. The four days at DPS headquarters changed that.

"The training class was by far the best of many trainings I've attended. The whole DPS team worked like a family."

Gilbert Clapp, Assistant Network Optimization Engineer

| Benefit | Impact |

|---|---|

| Direct Equipment Access | Hands-on practice with actual NetGuardian and T/Mon equipment |

| Customized to Real Needs | Training addressed Sparkplug's specific network monitoring challenges |

| Experienced Instructors | Taught by DPS engineers who designed and built the equipment |

| Collaborative Environment | Family atmosphere at DPS headquarters supported effective learning |

Monitor equipment with web configuration and multiprotocol support.

Centralized alarm master with control relays for managing remote equipment.

Discrete monitoring devices for comprehensive site visibility.

How do wireless ISPs monitor networks across multiple states? Wireless ISPs deploy remote monitoring systems at tower sites and infrastructure locations. RTUs monitor power, environmental conditions, and transmission equipment. Technicians receive immediate alerts when issues occur, enabling response before customers notice problems. This approach works across hundreds of remote sites and is considered an industry best practice for network reliability.

What should technicians learn in monitoring equipment training? Effective training covers protocol communication like SNMP and ASCII, web interface operation, and alarm configuration. Hands-on practice with actual equipment ensures technicians can configure, troubleshoot, and optimize monitoring systems. Most programs run three to four days and include custom applications relevant to your specific network. DPS factory training provides this comprehensive approach.

Can you control equipment remotely at unmanned tower sites? Yes. Alarm masters with control relay capabilities let you start generators, reboot equipment, or manage power from your NOC. This reduces truck rolls to remote locations and speeds response to outages. Control relays work through the same communication paths as your monitoring alarms. You configure control actions in your master software, then execute them when needed. This capability prevents minor issues from becoming major outages.

How do you monitor sites that lack IP connectivity? Multi-protocol masters support serial, dialup, and cellular communication in addition to Ethernet. This flexibility ensures monitoring coverage at every site. You can mix connection types across your network based on what's available at each location. Some sites might use Ethernet while others connect via cellular modem or serial link. The master station handles all protocols simultaneously, presenting unified visibility regardless of how each RTU connects.

Why attend factory training instead of reading documentation? Factory training provides hands-on practice with equipment and direct access to engineers who designed the systems. You learn real-world applications specific to your network. Documentation covers features, but training builds the competence to solve actual problems. Most customers find four days at the factory more valuable than months of trial and error. Hands-on technical training consistently shows better knowledge retention than documentation alone.

Give your team hands-on expertise with DPS factory training. Four-day programs in Fresno cover equipment operation, protocols, and applications specific to wireless ISP networks.

Or call us: 1-800-693-0351