Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWyoming telco brings monitoring in-house, cuts costs with IAM and RTUs

| Field | Details |

|---|---|

| Industry | Rural Telecommunications Provider |

| Company Type | Regional Telephone & ISP |

| Geography/Coverage | Worland, Wyoming - 16 exchanges |

| Primary Challenge | Aging equipment unable to support wireless expansion |

| Solution Deployed | IAM master station with NetGuardian RTUs |

| Key Result | In-house monitoring replaced third-party service |

| Products Used | T/Mon IAM, NetGuardian RTUs |

RT Communications has provided telecommunications services since 1994. The company is based in Worland, Wyoming. They maintain a subscriber base of 17,000 across 16 exchanges. RT Communications employs professional staff to deliver innovative services while maintaining care and integrity for customers.

RT Communications faced aging equipment that couldn't support their network expansion. Their mechanical exchanges had basic alarm capabilities. Upgrading to digital systems created a need for expanded features and intelligent call-out capabilities. RT Communications also relied on a third-party vendor to monitor western sites, creating ongoing costs and reducing direct control.

"Those systems were reliable in their day, but were not able to meet our needs when we went wireless."

Steve Keefer, Plant Manager, RT Communications

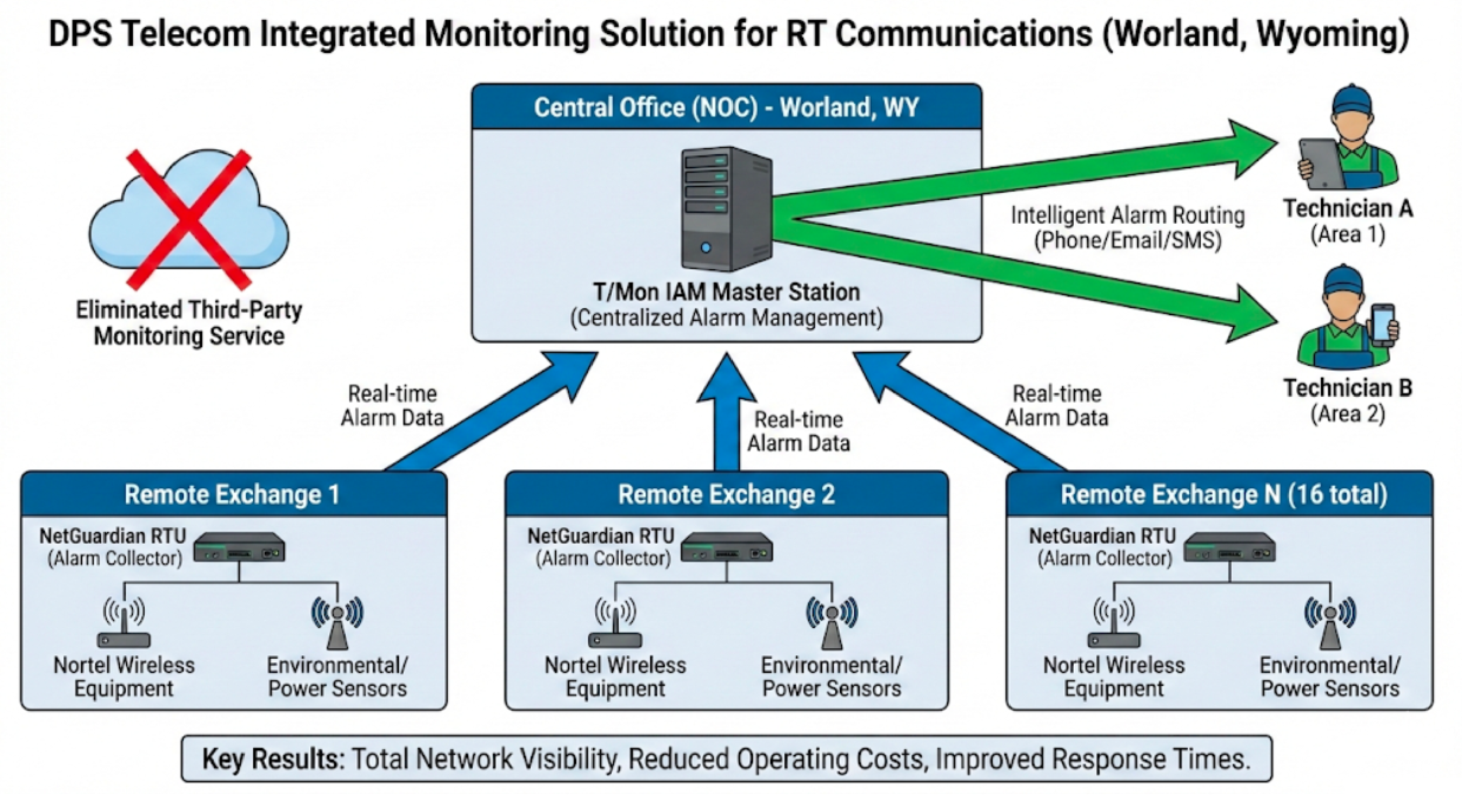

RT Communications worked with DPS Telecom to deploy a comprehensive monitoring system. The solution included the T/Mon IAM master station for centralized alarm management. Multiple NetGuardian RTUs were deployed across remote sites. Nortel recommended the system during their wireless equipment purchase. It integrated seamlessly with existing infrastructure.

The system delivered alarms directly to technicians with intelligent routing that sent each alarm to the person responsible for that specific area, improving response times and reducing confusion during network events.

The DPS implementation transformed RT Communications' network operations. The company gained total network visibility from a single location. They eliminated the need for third-party monitoring services. Each alarm now routes automatically to the responsible technician. This improved response times and operational efficiency.

| Outcome | Result |

|---|---|

| Reduced Operating Costs | Eliminated third-party monitoring service |

| Centralized Network Control | Complete visibility from central office |

| Intelligent Alarm Routing | Alarms delivered to responsible technician |

| Remote Site Integration | All remote huts connected to central office |

"It's a money-saving system because it allows us to keep our network monitoring in-house."

Steve Keefer, Plant Manager, RT Communications

| Benefit | Description |

|---|---|

| Direct Network Control | Complete network monitoring brought under direct control of internal team |

| Operational Cost Savings | Eliminated ongoing third-party monitoring expenses and vendor dependencies |

| Smart Alarm Management | Alarms automatically routed to responsible technicians based on location |

| Seamless System Integration | Easy integration with existing Nortel wireless network infrastructure |

NetGuardian RTU Series

LAN-based alarm collectors providing remote visibility of network elements

T/Mon IAM Master Station

Multiprotocol alarm master for centralized network monitoring

How do RTUs integrate with existing wireless infrastructure?

NetGuardian RTUs support multiple protocols and transport options, making them compatible with equipment from various manufacturers. They seamlessly integrate with existing wireless systems through standard protocols, requiring minimal changes to your current setup.

What alarms can be monitored at remote telecom sites?

RTUs monitor equipment status, environmental conditions (temperature, humidity, water intrusion), power systems (generators, batteries, rectifiers), and security (door contacts, motion sensors). This comprehensive monitoring protects both your network equipment and the supporting infrastructure.

How does centralized alarm management improve response times?

A master station like T/Mon aggregates alarms from all sites into a single interface and can route notifications to specific technicians based on location, alarm type, or equipment. This intelligent routing ensures the right person receives the alert immediately, reducing response times and preventing escalation of minor issues.

Can monitoring systems scale as the network expands?

Yes. DPS monitoring systems are designed for scalability. You can start with a few sites and easily add more RTUs as your network grows. The master station handles increased alarm traffic without requiring system replacement or major reconfiguration.

Why is in-house monitoring more cost-effective?

In-house monitoring eliminates ongoing service fees while providing greater control over your network. After the initial equipment investment, your only costs are maintenance and support. Additionally, your team gains direct visibility and can respond immediately without relying on external vendors to relay critical information.

RT Communications reduced costs and gained complete control over their network monitoring. Your telecommunications operation could achieve similar results.

Schedule a Free Consultation

Or call us: 1-800-693-0351