Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayDPS has just taken a major step to shorten the time line required to produce a new product by installing a computerized, metal-cutting, water jet at our Fresno facility.

Imagine the process of creating a new solution for a partner: defining need; splitting the task into its software and hardware components; ensuring that both heads of the process come back together just-in-time for the partner. But wait, it won't fit into the available housing.

Now add a minimum of 2 weeks; no, make that 4 weeks; OK, 8 weeks...This is the time frame that needs to be added to have a prototype metal housing fabricated by an outside vendor. This would be fine if we could start the metal design process before we get the initial query from the DPS partner, but that can't happen.

Enter Don Randall, full of experience, which includes knowledge of the metal fabrication industry and an ability to make things happen almost overnight. Don is turning our warehouse into a state-of-the-art prototype machine shop with a twist--we now have the very first, abrasive cutting water jet up and running in the Fresno-area.

Fabrication of metal parts with hard tooling has always been a lengthy process and adding the changes that are typical during prototype design often requires lots of extra time just to make the new tools according to Don. A water jet takes the same CAD drawing that we would have sent to the prototype shop in the first place and turns out the same parts from the same raw material--but it drops the fabrication time from 2 weeks to 3 minutes for a typical part.

"The beauty of this technique," Don said, "is that we basically use water and sand to perform the process. Nothing which harms the environment." The water jet takes ordinary tap water and pressurizes it to 55,000 pounds per square inch which can then be used to cut through paper, wood, cloth, and leather. Add a bit of grit to it (the same garnet which is used in sandpaper) and you can cut through an 8-inch chunk of steel!

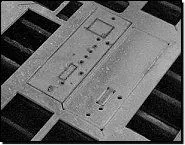

Well, we only need to cut through 1/8" steel and 0.090 aluminum for our panels and enclosures, so this is like a hot knife slicing through butter.

The real savings comes from the ability to "cut and try," moving a hole to a new location or adding a new cutout. With the out-sourced prototype, each iteration starts the process all over, adding tremendously to the overall cost. Now we just have to make the change in the CAD file, transfer it to the water jet and cut the parts--"printing to metal," a process which takes minutes instead of hours or days.

When the new machine shop is finished in a month or so, we'll have the ability to cut and form metal; apply a finish and add the silk screen according to a time line which meets the needs of our partners.