Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen you're responsible for remote tower sites, there's one scenario that immediately gets your attention: a lightning strike. It's unpredictable, it's dangerous, and if you're not prepared, it can take your critical equipment offline in seconds.

That's exactly what happened to one of our utility clients who was managing several remote tower sites. After experiencing what appeared to be a lightning event, they reached out to us at DPS.

We then had a technical conversation that illustrates a common challenge for many network operators:

How do you protect your gear from extreme events like lightning - without overhauling everything you already have?

Let's go through that conversation and talk about some key takeaways for anyone managing remote infrastructure. You'll see how one small change can lead to a better, more resilient monitoring strategy - without massive investment or unnecessary complexity.

The call started with one educated guess: "We think lightning hit one of our towers."

While their existing NetGuardian RTUs were still functional, the strike sparked an internal conversation about future protection. The real fear wasn't this event, it was the next one.

Lightning strikes aren't rare. They're a leading cause of equipment damage at remote sites, especially those with vertical infrastructure like towers. Even with proper grounding, surges can travel along connected metal surfaces, damaging gear that's not adequately protected or isolated.

And in many cases, the danger isn't total failure. It's hidden degradation.

A voltage spike might not always kill your RTU outright, but it can shorten its lifespan or silently compromise sensor readings. That's the kind of problem you don't discover until it's too late.

The hard truth is if you're not detecting electrical anomalies when they happen, your system might be blind to certain problems in the future.

Most organizations do what this client did: install proven monitoring hardware like the NetGuardian 432 series and wire up key alarms. That's a great start.

However, over time, you settle into routine operations. That is, until something like lightning shakes things up.

Some of the common issues we see with legacy or "good-enough" deployments include:

When something goes wrong (such as a lightning strike), you're left scrambling to figure out how to integrate something new without breaking the old.

During the call, we asked a key question:

"If one of your NetGuardians does get fried, would you want to replace it with the same exact model, or take the opportunity to upgrade to something newer?"

The answer was thoughtful and practical:

"We'd probably upgrade, especially if we're getting more capability for about the same cost."

That's the kind of future consideration we love to see. It's not about rushing into a massive replacement project. It's about building flexibility into your strategy. That way, when change is necessary, you move forward instead of backward.

For this client, the next logical upgrade is the NetGuardian G6 platform, which delivers:

This gives you a real path forward. You'll continue running existing RTUs until replacement is needed, then deploy the G6 with zero loss of functionality and a big step forward in capability.

It's like replacing an old work truck with a brand-new model. You get the same core utility again, but gain new functions and a refreshed lifespan.

Of course, RTUs are only part of the equation. The other side is what you connect to them.

After the lightning incident, the client was interested in monitoring voltage spikes. Specifically, they wanted to track if and when a tower is hit or affected by electrical surges.

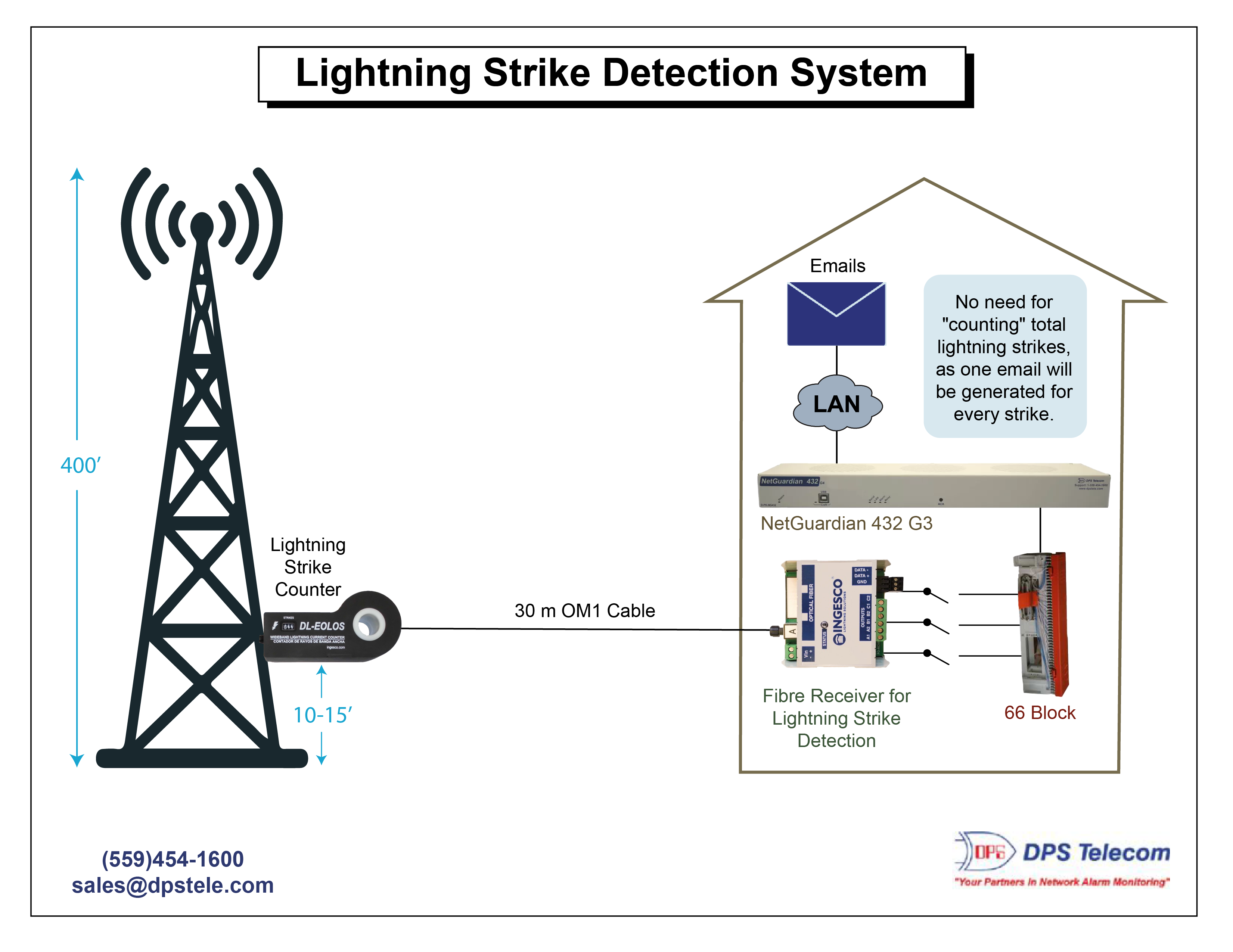

The good news is we have sensors that can do just that. These small metal detection modules clamp directly onto the tower or grounding path. They're designed for lightning rods, which means they detect the electrical pulse on its way down - without interfering with the grounding system itself.

Andrew offered to send detailed drawings and photos showing:

That last point is key: you only need one available discrete input (and an RTU with firmware that can count alarm+clear cycles over time) to make this entire setup work. And if that's not available, we can help expand capacity or recommend ways to daisy-chain sensors more efficiently.

One technical portion of the conversation revolved around the client's existing gear: specifically, the NetGuardian 432 G3.

This model features:

Understanding this wiring layout is important. As the client confirmed, most sensors were already in use (temperature, voltage, and water detection). But at least one discrete input remained open, which is all that's needed for the lightning detection module.

The client also asked about chaining sensors together, which is a strength of the NetGuardian platform. While sensors like temperature probes use RJ-11 connectors and daisy-chain easily, discrete alarms are wired through the Amphenol and require manual routing to punch blocks.

This kind of integration isn't difficult, but it does require a clear map. That's why we provide:

You don't have to guess. You just follow the diagram and connect it right the first time.

Toward the end of the call, the client summarized their approach:

"We'll start low and work our way from there. Maybe it's a science project."

That's the perfect mindset to have for your projects.

There's no need to turn a voltage detection idea into a company-wide rollout. Start with one site and install one sensor. Use one spare input on your existing RTU.

Once that's working, you'll have a repeatable template for the next site, and the next. You'll have visibility you didn't have before.

And if disaster strikes again, you'll have hard data that proves exactly what happened - down to the second.

This client's situation isn't unique. If you're responsible for remote infrastructure, here's what you should take away from this story:

Even if your gear survives a strike, voltage events degrade components over time. It's better to detect them in real-time than guess afterward.

You probably have 1 or 2 inputs free. That's all you need to monitor for electrical surges, tower grounding continuity, or similar.

Stick with what works. When it's time to replace an RTU, upgrade to something that moves you forward (like the NetGuardian G6 with dual NICs and enhanced capabilities).

Have drawings, pinouts, and schematics ready. If you don't have them, DPS will help you rebuild them.

The best monitoring strategies don't wait until after something breaks. They evolve gradually, with each improvement building on the last.

You don't need to launch a massive project to make your sites safer and smarter. All you need is the right guidance and a vendor who's committed to your long-term success.

That's exactly what DPS Telecom delivers.

Just like we did for this client, our goal is always to set you up for success.

If you're ready to take the next step (even if your project is just adding a sensor or two to an existing monitoring system) call or email us today:

Call: 559-454-1600

Email: sales@dpstele.com

Let's turn your remote site into a smarter, safer, and more resilient facility - one input at a time.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...