Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen evaluating remote monitoring solutions, DPS Telecom's NetGuardian RTU series and AKCP's sensorProbeX+ represent two distinct product categories. The comparison requires understanding not just specifications, but also how each platform approaches infrastructure monitoring. We've deployed over 172,000 monitoring devices across critical infrastructure networks, and the most important distinction is the product category itself.

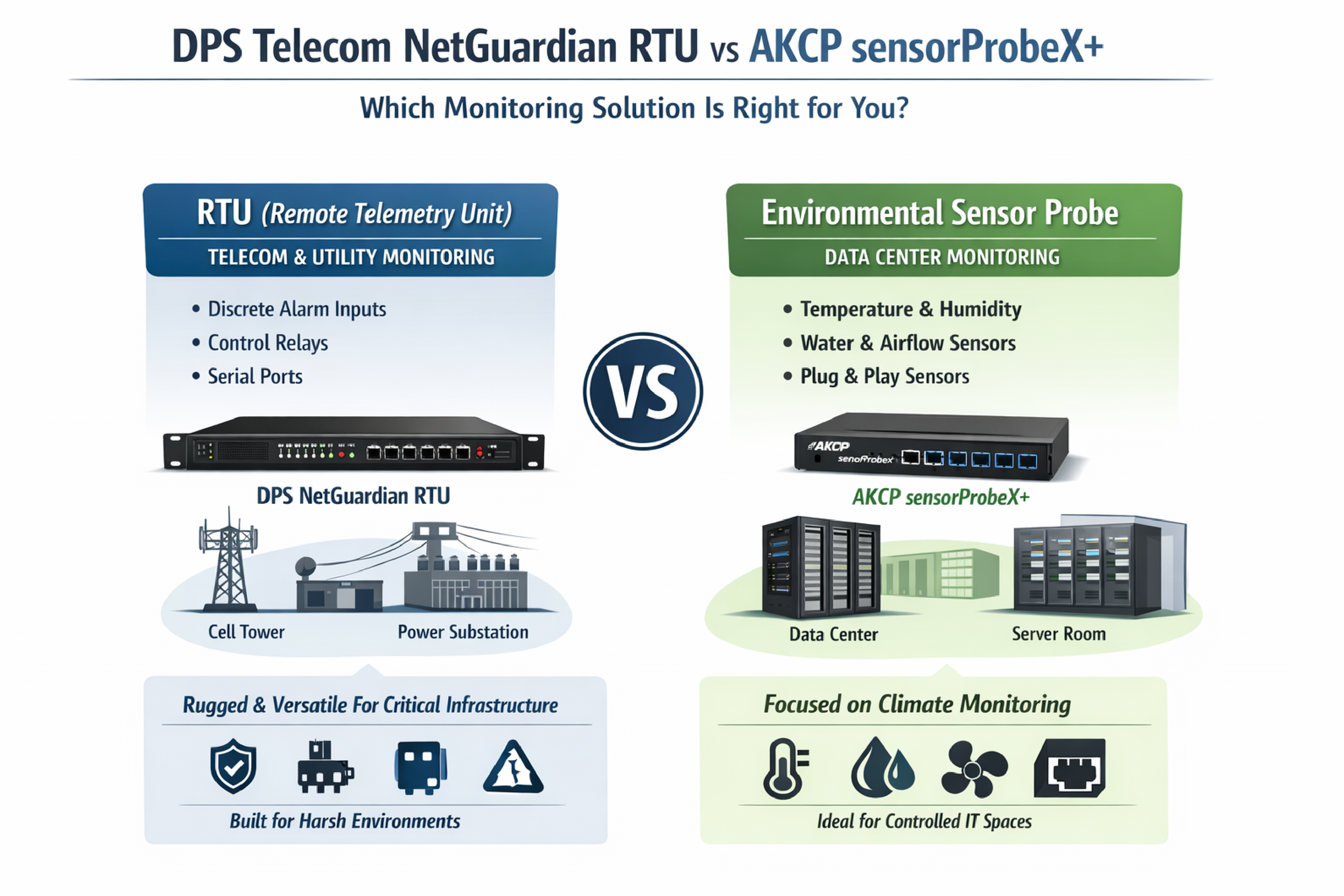

DPS manufactures Remote Telemetry Units (RTUs) designed for telecom, utility, and government networks. AKCP focuses on environmental sensor probes primarily for data center applications. This architectural difference influences I/O capacity, protocol support, manufacturing approach, and deployment models.

Note: The AKCP data in this comparison was gathered from published product information and technical documentation. Some specifications may vary by configuration or have changed since review. We recommend verifying current specifications with AKCP for specific deployment planning.

The distinction between an RTU and an environmental sensor probe determines what you can monitor and how you monitor it.

Remote Telemetry Units (RTUs) are hardened field devices defined in IEEE C37.1 (Standard for SCADA and Automation Systems). An RTU collects data from multiple sensor types (discrete contacts, analog inputs, control relays, serial ports) and reports alarm conditions to a centralized master station. RTUs are the standard monitoring device for telecom central offices, cell towers, power substations, and unmanned facilities. They're designed for uncontrolled environments where equipment operates outdoors or in minimally maintained shelters.

Environmental sensor probes are IP-based devices that track environmental conditions such as temperature, humidity, water detection, and airflow. These devices originated in the data center market, where controlled IT environments require precise climate monitoring. They typically emphasize environmental awareness over equipment alarm integration.

This architectural difference shapes each platform's capabilities. The NetGuardian 832A supports 32 discrete alarm inputs (expandable to 176), 8 control relays for remote equipment operation, and 8 serial ports for console access. This design serves organizations monitoring equipment alarms from switches, rectifiers, generators, and other telecom/utility gear.

The sensorProbeX+ excels at plug-and-play environmental monitoring with its 8 intelligent sensor ports and modular expansion approach. This design serves organizations prioritizing environmental conditions over equipment alarm integration. The different architectures mean each platform optimizes for distinct use cases rather than competing directly.

Here's how the platforms compare across key technical specifications:

| Specification | AKCP sensorProbeX+ | DPS NetGuardian 216 G3 | DPS NetGuardian 832A G6 |

|---|---|---|---|

| Discrete alarm inputs | Limited (via dry contact converter sensors) | 16 (isolated) | 32, expandable to 176 |

| Intelligent sensor ports | 8 RJ-45 (proprietary AKCP sensors) | N/A (uses standard 0-5V, 4-20mA, dry contact) | N/A (uses standard interfaces) |

| Analog inputs | Via sensor ports (proprietary) | 2-8 built-in (4 thresholds each) | 8+ built-in (4 thresholds each) |

| Control relay outputs | 0 | 2 | 8 |

| Serial reach-through ports | 0 | 1 | 8 (terminal server function) |

| Ping monitoring | Limited | Up to 32 devices | Up to 32 devices |

| Network interface | 10/100 Ethernet | 10/100 Ethernet | 10/100 Ethernet with built-in switch |

| Protocols | SNMP v1/v2c/v3, HTTP/S, Modbus TCP, MQTT | SNMP v1/v2c/v3, DCP(x) | SNMP v1/v2c/v3, DCP(x) |

| Operating temperature | 0 C to 55 C | 0 C to +60 C (extended: -30 C to +70 C) | 0 C to +60 C (extended: -30 C to +70 C) |

| Power input | 12V DC adapter or PoE | -48VDC telecom, dual-feed DC, or AC | -48VDC telecom, dual-feed DC, or AC |

| Form factor | 1U rack-mount or desktop | 10.5" x 6.6" x 1.7" | 1U, 19" rack-mount |

| LCD/LED display | No (web interface only) | No | Yes, with 16 status LEDs |

| Manufacturing location | Thailand | Fresno, California, USA | Fresno, California, USA |

| Central management | AKCPro Server software | T/Mon LNX master station (30+ protocols) | T/Mon LNX master station (30+ protocols) |

AKCP uses a proprietary sensor bus with RJ-45 connectors. Their "Intelligent Sensors" auto-detect when plugged in, which AKCP describes as simplifying deployment. This approach may require AKCP-specific sensors rather than third-party alternatives. For organizations integrating dry contacts or 4-20mA signals from existing equipment, converter modules can bridge the gap between standard interfaces and AKCP's sensor bus.

We designed NetGuardian RTUs to accept industry-standard sensor interfaces: 0-5V, 4-20mA, and dry contacts. This design choice allows clients to source sensors from any manufacturer and integrate existing equipment without converter hardware. When a telecom carrier needed to monitor legacy equipment spanning three decades, the NetGuardian interfaced directly with their existing infrastructure using standard connections.

Our D-Wire sensors use a standardized RJ-11 interface with plug-and-play detection similar to AKCP's approach, but they're optional rather than required. You can mix D-Wire sensors with traditional analog inputs on the same RTU, providing flexibility when some sensors use standard interfaces while others benefit from plug-and-play convenience.

Beyond environmental monitoring, some infrastructure applications require remote control of equipment. This is where RTU and sensor probe architectures diverge.

The NetGuardian 832A provides 8 control relay outputs that enable remote management of generators, power cycling equipment, door lock release, or HVAC system control. These capabilities can reduce truck rolls to remote sites. At a Nevada utility, our control relays eliminated an average of 12 truck rolls per month by allowing technicians to remotely reset equipment and cycle power.

The sensorProbeX+ focuses on monitoring and alerting. Organizations requiring control capabilities may deploy separate equipment for remote operations alongside AKCP's monitoring platform.

Serial reach-through represents another architectural difference. The NetGuardian 832A includes 8 serial ports that function as an integrated terminal server. These ports allow technicians to remotely access console ports on routers, switches, and other equipment. This integrated approach eliminates the need for separate terminal server hardware. The sensorProbeX+ architecture emphasizes environmental sensor integration over serial connectivity.

For organizations managing multiple sites, centralized alarm management becomes important. Different platforms approach this requirement differently.

Our T/Mon LNX master station provides centralized alarm management across distributed networks. T/Mon aggregates data from all NetGuardian RTUs into a single geographic-map interface. It mediates over 30 protocols, including SNMP, DNP3, Modbus, TL1, and various legacy formats. This protocol mediation allows integration of equipment spanning multiple generations and manufacturers.

AKCP's AKCPro Server software provides centralized management for multiple AKCP units. According to AKCP's documentation, AKCPro offers features like floor-plan mapping and virtual sensors for calculated values. The platform integrates with third-party systems via SNMP.

The NetGuardian 832A's expansion from 32 to 176 discrete alarm points via expansion shelves means a single device can grow with a site over time. This follows the telecom approach of deploying one RTU per site, which reduces IP address requirements and simplifies documentation.

AKCP's expansion model uses additional modules (EXP and BEB units) to scale up to 400 sensors per base unit. This modular approach works well for data centers with high sensor density in a single location.

Manufacturing origin has become a significant procurement factor for organizations involved in government-funded infrastructure projects. We design, manufacture, and test every product at our 28,000-square-foot facility in Fresno, California. AKCP manufactures in Chonburi, Thailand.

This distinction carries concrete regulatory implications:

Build America, Buy America Act (BABA): Enacted as part of the Infrastructure Investment and Jobs Act (Public Law 117-58, Sections 70901-70927), BABA requires that manufactured products used in federally funded infrastructure projects be produced in the United States. With $1.2 trillion in infrastructure spending flowing through federal grants covering telecommunications, broadband, and utility infrastructure, this requirement affects a growing share of monitoring equipment procurement. Our products satisfy BABA requirements without waivers. Products manufactured in Thailand would require waivers, adding procurement time and administrative burden.

Buy American Act (BAA): The traditional BAA (41 U.S.C. §§ 8301-8305) requires federal agencies to prefer domestically manufactured goods. The current domestic content threshold stands at 75% and continues to rise. US-manufactured products like ours inherently satisfy BAA requirements.

Trade Agreements Act (TAA): Thailand is listed as a TAA-designated country under FAR 25.003, which means AKCP products may technically qualify for GSA Schedule purchases. However, many state and municipal agencies operate under stricter Buy American preferences that favor US manufacturing regardless of TAA status.

For organizations working with federal grants for rural broadband, FirstNet buildouts, or utility modernization, compliance paperwork is simplified when your monitoring equipment is US-manufactured.

We provide a 2-year hardware warranty with all NetGuardian RTUs, backed by free technical support from our California headquarters. When clients call, they reach engineers who designed the products rather than call center staff. We don't charge for firmware upgrades during the warranty period.

AKCP typically offers a 1-year warranty through distributors. AKCP provides support through their technical forum and documentation portal. Firmware updates are available through their support portal.

Both companies offer extended warranty options and have global distributor networks. The choice often comes down to whether direct manufacturer support or a distributed support model better fits your organization's preferences.

Both platforms support SNMP v1, v2c, and v3 for integration with network management systems. This is the foundation that makes either option viable for most infrastructure monitoring applications.

AKCP adds Modbus RTU/TCP support and optional BACnet licensing for building automation integration. This makes the sensorProbeX+ well-suited for facilities running BACnet-based building management systems. Organizations already invested in BACnet infrastructure may find this integration capability valuable.

We focus on telecom and utility protocols. Our T/Mon master station mediates DNP3 for utility SCADA integration, TL1 for telecom networks, and various protocols from earlier-generation equipment. If you're monitoring a mixed environment with telecom gear, utility equipment, and IT infrastructure, protocol mediation capability becomes particularly important.

Both platforms offer SNMPv3 with authentication and privacy for secure alarm reporting. Both support HTTPS for web interface access. Both allow multiple user accounts with configurable permissions.

The NetGuardian 832A's dual NIC configuration provides an additional security option by allowing organizations to isolate management traffic from production networks. One NIC can connect to a secure management VLAN while the other interfaces with site equipment. This separation can be valuable in environments where network segmentation is part of the security architecture.

AKCP offers optional RADIUS and TACACS+ licensing for organizations that require centralized authentication management through existing identity systems.

The decision typically comes down to what you're monitoring and how your infrastructure is configured.

Consider the sensorProbeX+ when:

Consider DPS Telecom NetGuardian RTUs when:

The fundamental question is whether you're monitoring environmental conditions in a controlled facility or managing alarms from critical infrastructure equipment across distributed sites. Environmental sensor probes optimize for the former. RTUs are engineered for the latter.

Whether you choose an RTU or environmental sensor probe, proper site survey and requirements definition are essential first steps. Document every alarm point you need to monitor, every piece of equipment you may need to control, and every protocol you need to support. This prevents costly redesigns after deployment.

For organizations monitoring 10 or fewer sites with straightforward requirements, standalone units with built-in web interfaces may suffice. Beyond that scale, centralized alarm management through a master station or NMS platform typically becomes valuable.

Yes. RTUs like the NetGuardian series can monitor environmental conditions using standard analog sensors for temperature, humidity, water detection, and other variables. The difference is that RTUs use industry-standard 0-5V or 4-20mA sensor interfaces rather than proprietary sensor buses.

RTUs deployed in telecom and utility applications often remain in service for 20+ years. Environmental sensor probes typically have shorter deployment cycles aligned with data center equipment refresh schedules. Product longevity depends on component quality, environmental conditions, and manufacturer support commitments.

This varies significantly by application. A small cell tower might require 8-16 alarm points (door, temperature, rectifier, generator). A central office could require 32-176 points across multiple equipment racks. A data center might prioritize environmental sensor density over discrete alarm points. Conducting a thorough site audit is the best way to determine actual requirements.

Organizations with fewer than 10 sites often manage individual units through web interfaces. Beyond that scale, a master station or centralized NMS typically becomes valuable for alarm aggregation, consistent alarming policies, and simplified operations.

At DPS Telecom, we offer free consultations to help you specify the right monitoring solution for your infrastructure. Our application engineers review your site drawings, alarm requirements, and existing equipment to recommend configurations that fit your needs. Contact us to discuss your specific monitoring requirements and receive a detailed technical proposal.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...