Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMontana cooperative prevents outages with proactive equipment monitoring.

| Field | Details |

|---|---|

| Industry | Rural Telecommunications |

| Company Type | Telephone Cooperative & ISP |

| Geography/Coverage | Rural Montana Communities |

| Primary Challenge | Preventing service-affecting outages on critical equipment |

| Solution Deployed | Redundant T/Mon master stations with NetGuardian RTUs |

| Key Result | Caught generator relay failure before customer impact |

| Implementation Timeframe | Phased over several years |

| Products Used | T/Mon Master Stations, NetGuardian RTUs |

Nemont Telephone Cooperative was organized in 1950 by rural residents who wanted telephone service. Today, the cooperative provides cellular, telephone, internet, and cable TV services to rural Montana communities. The cooperative has gained recognition for deploying broadband in underserved areas.

For a rural cooperative serving dispersed customers, prolonged outages are unacceptable. When equipment fails in remote locations, customers lose phone service, internet, and emergency communications. Greg Larson and Ron Weed, Central Office Technicians at Nemont, needed to monitor service-critical equipment before failures occurred.

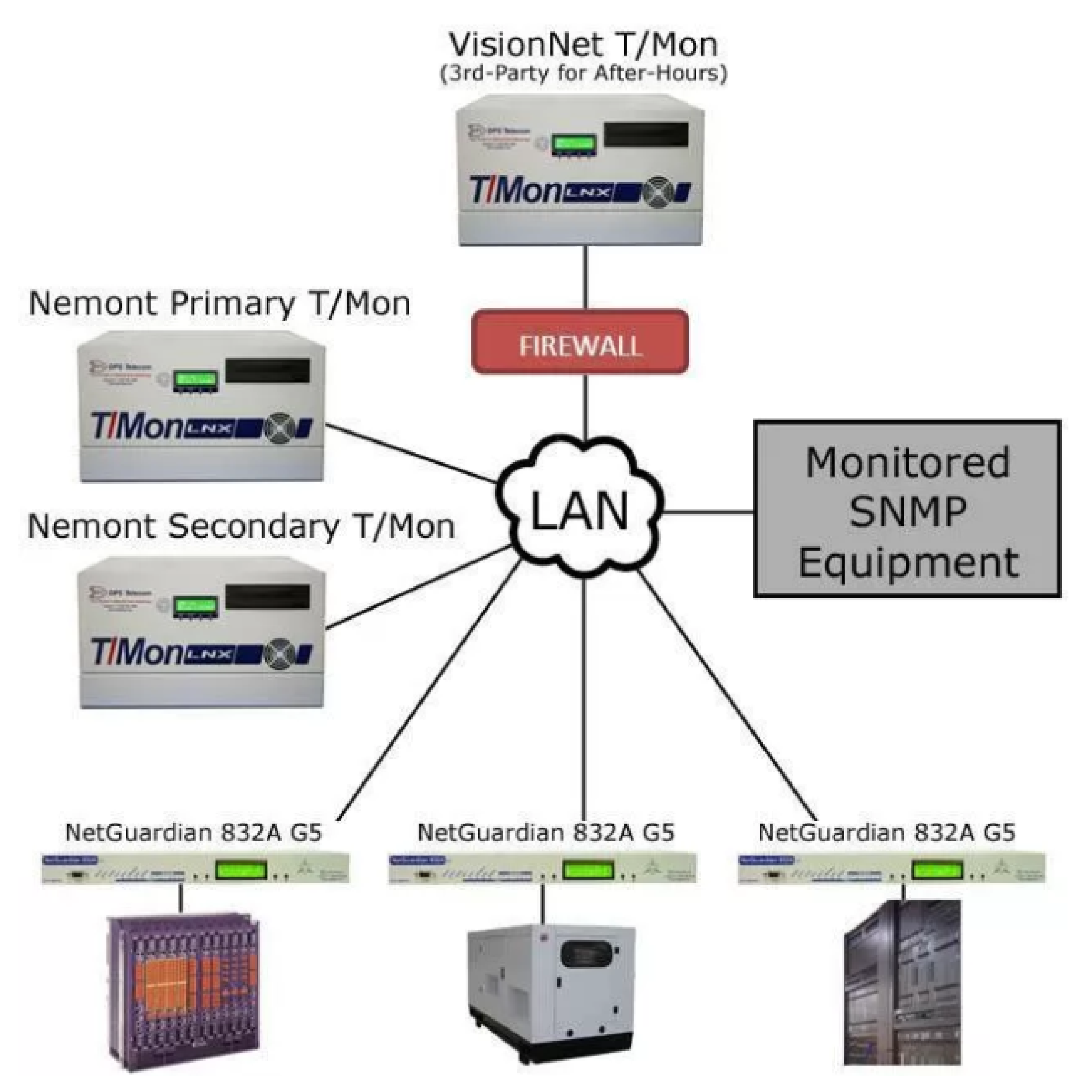

Nemont deployed T/Mon master stations with redundant configurations to create a comprehensive monitoring system. NetGuardian RTUs at remote sites collect data from critical equipment and report status back to the central T/Mon systems.

The redundant T/Mon architecture ensures monitoring continues even if one master experiences issues. All service-affecting equipment has configured alarms to alert technicians before problems escalate.

Factory Training Attendance Larson and Weed attended multi-day training at DPS headquarters in Fresno, California in September 2012.

Hands-On System Configuration The training covered system architecture, alarm setup, troubleshooting procedures, and upcoming developments.

Advanced Capability Preview The team previewed T/Mon Web 3.0, enabling both monitoring and configuration from a web browser.

Enhanced Team Confidence "I feel much better about going back and doing things now," said Weed. "You need the hands-on stuff we did here."

The proactive monitoring system delivers early warning of equipment problems before they affect customers. When a generator relay failed, the system immediately alerted technicians, who replaced it during normal business hours rather than during an emergency outage.

"Any equipment that we have that is service affecting, we have alarms on it. Things like transport equipment, DMS 10s, AFCs, etc."

Ron Weed, Central Office Technician, Nemont Telephone

| Metric | Result |

|---|---|

| Proactive Problem Detection | Generator relay caught before power failure |

| Complete Equipment Coverage | All service-affecting equipment monitored |

| Continuous System Reliability | Redundant masters ensure continuous monitoring |

| Enhanced Team Confidence | Training improved technician capabilities |

| Benefit | Impact |

|---|---|

| Prevented Service Outages | Early warning system catches problems before customer impact occurs |

| Improved Operational Efficiency | Remote monitoring reduces costly emergency site visits significantly |

| Enhanced System Reliability | Redundant architecture ensures continuous equipment oversight |

| Stronger Technical Staff | Factory Training builds comprehensive technical capabilities |

T/Mon Master Stations Multiprotocol network alarm management with redundant architecture.

NetGuardian RTUs Remote units collecting equipment data at distributed sites.

Focus on service-affecting equipment: transport systems like fiber gear, telephone switches, backup generators, and environmental systems. Any equipment whose failure would interrupt customer service deserves monitoring. For rural cooperatives, backup power systems are particularly critical since grid power may be less reliable.

How does redundant monitoring improve reliability?Redundant T/Mon master stations ensure monitoring continues even if one master experiences problems. This architecture is especially important for organizations serving rural areas where any monitoring outage could mask critical equipment failures. The redundant configuration provides backup without requiring manual intervention.

Why is hands-on training important for monitoring systems?Modern monitoring systems offer sophisticated capabilities that require proper training to fully utilize. Factory Training at the manufacturer's facility provides hands-on experience that manuals alone cannot deliver. Technicians learn not just what buttons to push, but why certain configurations work better than others.

Can monitoring systems integrate with different manufacturers?Yes. DPS equipment supports 30+ protocols including SNMP, Modbus, and manufacturer-specific protocols. This allows monitoring of equipment from Calix, Nokia, Cisco, generator manufacturers, and other vendors within a single platform. The multiprotocol capability is especially valuable for rural providers who often have mixed equipment environments.

What's the typical ROI for remote monitoring in rural telecom?Preventing a single major outage typically justifies the entire monitoring investment. Consider the cost of emergency truck rolls to remote sites, overtime labor, lost revenue during outages, and potential regulatory penalties. Rural providers face higher costs per incident due to distance and limited staff, making proactive monitoring especially cost-effective.

Remote sites and critical infrastructure demand reliable monitoring. See how DPS Telecom helps prevent outages and improve service reliability.

Get a Free Consultation | Or call us: 1-800-693-0351