Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

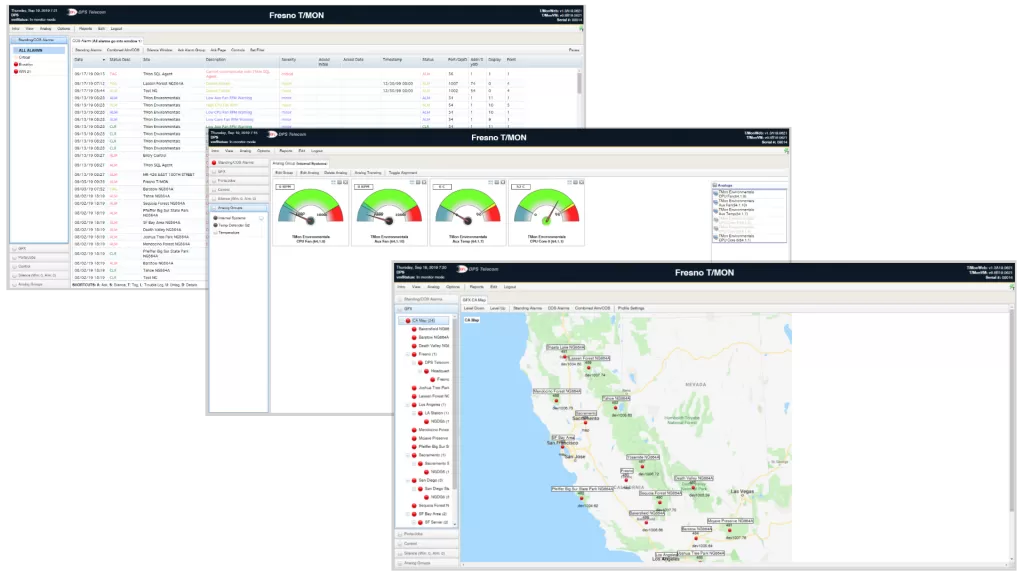

Graphic user interface (GUI) for smart management and visibility

"Large" has many dimensions. Commonly, we think of a large company as one which has a significant number of employees. But describing a company as large can also signal a widespread physical footprint, like hundreds of telecom towers or thousands of gas wells.

Even if businesses don't sprawl hundreds of miles, they can have hundreds of pieces of hardware in operation to keep track of, like a hospital might.

Company magnitude extends in another direction as well - time. In this sense, companies, like fish or trees, are constantly growing larger as they grow older. Why does this matter? Because larger companies are more difficult to monitor and manage.

A company that has been installing equipment for the last 30 years will have a vast range of different equipment styles and capabilities to rationalize. As you know if you have teenagers, being years apart means you may not even speak the same language.

Developing and implementing successful company strategies depends on accurate, comprehensive information about a company's operation. The larger a company is in every dimension, the more difficult it is to implement a successful strategy.

In these cases, company managers must find ways to make the amount of information they must process more easily visible.

In particular, instead of dealing with a scattered Babel of hardware languages squawking from the four corners of the wind, large companies can use uniform SNMP in networking and monitoring their hardware.

SNMP stands for Simple Network Management Protocol. It's a hardware Esperanto, a lingua franca, a common tongue shared by many different types and ages of equipment.

Not every piece of equipment can transmit information in SNMP, but many can. Those which can't would instead transmit to central master stations, which will convert Modbus, DNP3, or other machine dialects into the common SNMP protocol.

What's the benefit of having so many pieces of hardware speak the same language? It allows them all to be monitored and viewed from a central location.

So a company with widespread infrastructure can visibly see its entire operation on a computer screen. Able to access this comprehensive, accurate information, company leaders can develop, implement, and monitor successful management and maintenance strategies.

This information can significantly improve maintenance results, reducing expensive downtime. Depending on the equipment, downtime can have expensive primary and secondary consequences.

Companies often rely on pre-scheduled preventative maintenance schedules to assign their limited maintenance resources. This is most effective for maintenance issues that fall in the fat center of the bell curve, not for outlier issues. Monitoring hardware via SNMP improves this strategy in two ways:

As the Internet of Things becomes bigger and bigger, more and more equipment will transmit its own sensor information in SNMP. The only step company managers need to take in this case is to ensure that new equipment actually does this, and can interface with the company's existing network.

To simplify communications, this equipment should transmit information to master stations which can retransmit data to the alarm mediation master.

Older equipment may transmit information on its own, just not in SNMP. For this equipment, as previously discussed, the best method is to arrange transmission to a master station. The master station will translate and then re-transmit to the alarm mediation station, where it can be viewed.

Some equipment, older and even sometimes modern, won't transmit any information at all. In order to monitor this equipment remotely, separate devices known as Remote Terminal Units (RTUs) are required. RTUs can be configured with a wide range of sensors relevant to equipment conditions, such as temperature, humidity, battery levels, tank levels, or vibration.

Rather than constantly broadcasting a sea of noise, RTUs keep communications streamlined by transmitting only important events to master stations. Doing so allows the central alarm mediation master to update its information solely from master stations, saving processing power.

And, for greater visibility, some master stations even offer graphic user interface (GUI) capabilities to enable management to view geographical details on maps and charts.

Companies with older equipment, which transmit in different protocols or not at all, can still implement comprehensive monitoring by using RTUs and master stations to transmit and convert relevant equipment data.

Using SNMP in networking for large company operations improves the ability of managers to effectively strategize and simplify communications.

DPS Telecom can help bring your legacy equipment into your network. To take advantage of our deep experience with SNMP and equipment networks, reach out and get a quote today!