Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

"Every one of us knows that we work for the client," says Annette Rinehart, manager of DPS Telecom's Production Department.

Rinehart and her staff are responsible for building and shipping DPS products, but they see themselves first and foremost as a client service force.

"The clients drive everything we do," said Rinehart. "The client is who we work for. The client is who we have to satisfy. Because if anything goes wrong, it's the client who we've let down."

"My personal promise to each and every DPS client is that we ship a quality product, on time or ahead of time," said Rinehart.

Rinehart has been with DPS Telecom for eight years. She started out wiring KDAs, and in her time she's worked every job in the Production Department.

"I love the challenge of this job. I love it that everything changes and it's different. I love seeing how things work, and I like going to the next step," Rinehart said.

Every single DPS product is built and tested under Rinehart's strict supervision. At a time when most manufacturers leave the actual manufacture of their products to outsource suppliers, DPS continues to build all its products in-house in its own production facilities.

This strategy of concentrating control of manufacturing within DPS is called vertical integration, and it's an essential part of DPS's client-first service philosophy.

Outsourced manufacturing is cheap for the vendor, but it's punishment on the client. With outsourcing, shipment times stretch out as the primary manufacturer waits on his suppliers. And the quality of the components is entirely in the hands of the subsidiary manufacturers.

Because DPS controls every phase of the manufacturing process, production bottlenecks and quality problems are eliminated at the source. Greater efficiency brings direct benefits to the client - fast shipping times and guaranteed quality.

Vertical integration makes DPS's custom design services possible, Rinehart said. "Some of our clients require special design modifications, and you can only do that if you do the manufacturing yourself. How could you get that done by anybody else? Our clients have interfaces and design requirements that are unique to them, and you can only meet those hands-on," Rinehart said.

There are three stages to DPS's manufacturing process:

Let's look at how these processes work together in building a NetGuardian 832A remote telemetry unit.

Metal work begins with cutting the raw material - aluminum - with a high-powered jet of garnet and water. At 50,000 PSI, the water jet cuts the metal to a tolerance of 0.004 inch in less than five minutes.

DPS's in-house metal shop is a perfect illustration of the advantages of vertical integration. If metalwork was outsourced to a stamp-and-die works, it would take up to six weeks to complete a design. If a design needed to be changed, that would take another six weeks. The water jet can be adjusted whenever it's needed, so new case designs can be built fast.

The cut metal is shaped by the press brake, which operates with 10 tons of hydraulic pressure. The press brake is computer-controlled, fast and precise.

The shaped case is coated with a powder coating that's more durable, scratch-resistant and rust-resistant for weather tolerance than regular paint. "The powder won't flake, it won't fall off, it won't let moisture and rust in," said Rinehart.

The powder is fused to the metal with 15,000 volts of static electricity, then baked to seal the finish.

Case graphics for control and connector labels are silk-screened onto the case. The design is created using graphics software, and the design goes straight from there to the software controlling the silkscreen machine. Changing the silkscreen to accommodate a client's custom design only requires a new design file.

After the silkscreen is applied, the case is baked a second time to make sure the finish is extra durable.

There aren't any stops in the manufacturing process - circuit boards are built at the same time that cases are made.

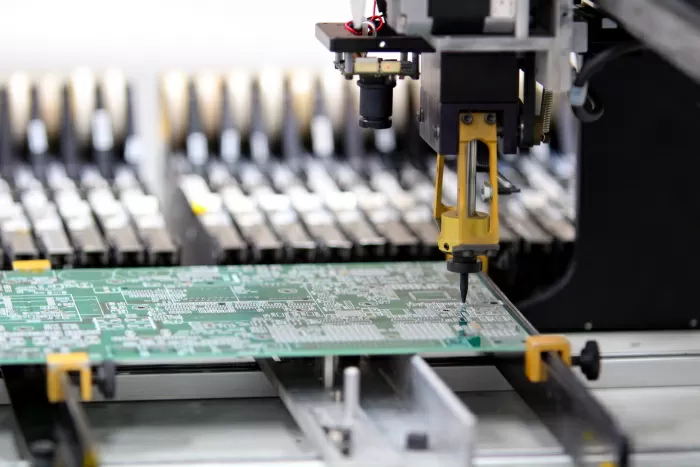

Circuit board designs go straight from the engineer's computer to automated manufacturing machinery. Circuit board manufacture is automated as much as possible - it's fast, eliminates extra steps and keeps the boards clean.

The board is coated with a solder paste and small components are surface-mounted on both sides of the board, providing greater component density. DPS's surface mount machine picks up components with a vacuum head and places them on the board with an accuracy of a thousandth of an inch - that's one-twentieth the thickness of your thumbnail.

Larger parts like resisters, diodes, capacitors and transistors are inserted by axial and radial insertion machines, or by hand. Then the parts are soldered in place by a wave solder process.

Automating the board manufacture process allows a small crew to create a large production, said Rinehart. "If I were to build a NetGuardian totally by hand, it would take hours and hours. Two to three people operating our machines can run 75 to 100 boards. I don't have a large crew, but with machines, they can produce a lot."

Rinehart said she further maximizes the value of her staff by cross-training each staff member on multiple tasks. If one worker has to take a sick day, other steps in his or her place and manufacturing continue uninterrupted.

Quality assurance checks happen at every stage of the manufacturing process, and then boards are run through a battery of tests after they're completed.

"We have quality assurance checkpoints for every step," Rinehart said. "So, for example, after a board is run through the surface mount machine, the worker follows a check sheet and makes sure there's no cold solder or misplaced parts. For every point, whether it's surface mounting, machine insertion, hand building, it's QA'd before it goes into the solder room, and after it's soldered, it's checked again. There's a final QA on the finished unit, of course, but there's an initial QA point for every manufacturing process."

DPS never does statistical testing - each board is individually run through a full battery of functional tests and is then placed in a burn chamber overnight, to assure that the product will operate under extreme conditions.

Once the boards are burned in, the NetGuardian unit is fully assembled. The circuit boards are mounted in the chassis, connectors are attached, and everything is secured together.

Finally, the finished NetGuardian goes through a second full battery of tests, run by a second technician. Every unit is tested at least twice, by separate technicians, for quality control.

For Rinehart, increasing the speed and efficiency of the Production Department is a matter of meeting her responsibility to DPS clients. "The client sets the schedule by telling us when he wants the delivery. When an order comes in the first thing I do is look at the due date and figure out what I need to do to meet or beat that delivery date. One of my main goals is to ship before the due date."

Rinehart added that DPS's Production Department has a history of continuous improvement. "We've definitely gotten faster over the years. We've learned how to use our machines better, we've learned how to schedule our time, and we've learned from our mistakes. Compared to where we were several years ago, we've improved by at least 50%, and hopefully next year we'll improve even more, because we keep learning more," Rinehart said.

NetGuardian 832A: Quality Built to Protect Your Network

The NEBS-certified NetGuardian 832A's built quality is matched only by its capabilities. Mediate contact closures to SNMP traps, get built-in email alarm notification,access remote site equipment through terminal server ports, learn everything the NetGuardian 832A can do for you.