Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayEver since its release in the 1970's, many businesses have implemented networks based on the standard Modbus communication.

The protocol itself is quite universal. This is unlike many vendor-specific standards that have been created over the years with the intent to "lock-in" customers to one single product line. Modbus is commonly supported by many vendors because of the open-publication rights as well as the ability for devices from several generations and companies to send communications back and forth efficiently.

As time has passed, bringing many technological advancements, this protocol still remains the choice of many network officials. The easy deployment and maintenance has also allowed many to build a network up gradually as the needs arise, contributing to saving time and money during any repair work.

Are you currently exploring your options in terms of Modbus network monitoring solutions? Do you have devices that support Modbus?

It's important to follow Modbus best practices in order to get the most out of your remote monitoring applications. However, mixing legacy Serial Modbus with modern IP networks creates integration headaches. At DPS Telecom, we have helped hundreds of utilities bridge this gap. Based on our deployment experience, here are the three absolute best practices for stabilizing a Modbus network.

The Modbus protocol has evolved into several different variations. These variations are designed to support Modbus network communications over a variety of physical network layers. These variations include Modbus RS-232 and Modbus RS-485, which will support different types of serial line connections.

There is another variation called Modbus TCP/IP communication protocol.

The Modbus TCP/IP specification was created in response to the expanding usage of Ethernet. Since TCP/IP is the transport protocol of the Internet, Modbus TCP/IP - which is simply the Modbus protocol wrapped with TCP/IP - can be used to communicate over a Modbus network structured with an IP connection.

TCP/IP networks are used as the transport protocol of the internet and is made up of two different protocol layers.

The first layer, the transport layer, called the Transmission Control Protocol (TCP) is used to break up the message structure or file into smaller pieces of data called packets that are then sent over the internet. It's also responsible for rearranging the packets when it receives them.

The second layer, the Internet layer, called the Internet Protocol (IP) is used for addressing the packets so that they get to the correct destination.

Modbus TCP/IP protocol provides a huge set of capabilities because of its compatibility with other TCP/IP support devices and software. For instance, if you have a Modbus TCP/IP device that is located halfway across the world in a remote location, you can access it through the internet due to the TCP/IP feature.

As I said previously, Modbus serial is the original variant of Modbus that travels over a serial connection. This serial connection commonly uses an RS-232 or RS-485 serial interface. Modbus TCP is an extra variant of the Modbus protocol. Internet users can access Modbus TCP at port 502, which is reserved for Modbus users on TCP/IP stack.

Today, Modbus TCP has become a popular variant of the Modbus protocol. So, a Modbus bridge will allow users to transition to this variant, while still making use of their Modbus serial gear.

A Modbus bridge may be configured as a Slave or a Master bridge, simply by connecting to either device serially. A Modbus bridge can also be used for other Modbus variants, such as Modbus ASCII and Modbus RTU.

With a Modbus bridge, users can connect thousands of slave devices using a single Ethernet card and the Modbus TCP protocol. Devices joined to a Modbus bridge have single IP addresses, and addressing slaves through the Modbus bridge is now defined by the IP address and the slave address (slave id).

When a Modbus bridge receives a Modbus TCP request, it converts the messages into Modbus RTU or other variants of this protocol, creating a response using Modbus TCP. In these cases, the Modbus master device most likely does not even see that it is not actually communicating with a Modbus TCP device.

Also, keep in mind that a Modbus bridge can connect to many Modbus TCP masters at one time. Serial slaves will actually see the Modbus bridge as the master device. The actual TCP Modbus master will treat the Modbus bridge like a group of slaves, communicating as if every single master had sole access to the slave devices. With more masters accessing the Modbus bridge, response times can become slightly slow.

When seeking a master for your Modbus network and other devices, you should look for a master that can bring your Modbus alarms and notifications from your other protocol devices into one master screen. This will help you monitor your network as efficiently as possible, eliminating the need for multiple operators and workstations to accomplish your network alarm monitoring.

A Modbus Human Machine Interface (HMI) is the interface of a Modbus system that allows the operator to interact with the system gear. This interface is a type of software that presents the Modbus messages in a human-readable form.

A Modbus HMI is vital for an operator to be able to read alarm polls and status reports from their Modbus system. As Modbus communications take the form of packets of word bits, it would be very hard - and time-consuming - for an operator to manually interpret even a single Modbus message.

With thousands of alarms and response messages coming in every day, it would be impossible for an operator to monitor their network without a Modbus HMI. This is why a Modbus HMI is so necessary. It decodes the Modbus protocol and translates them into a human-readable language.

Typically, a Modbus HMI is a type of browser screen. In this screen, network staff can view their Modbus alarms and other messages in their English form. The HMI simply uses the codes programmed into the system to retrieve the information from the packets of bits.

When looking for a Modbus HMI, it's important to find the most user-friendly interface you can. With familiar Windows controls, you can be certain your staff will quickly become comfortable with your new Modbus HMI.

You should also look for an HMI that provides custom alarm grouping. This will allow you to categorize your Modbus alarms based on the severity, geographic location, or any other criteria that will help your operator to most efficiently dispatch your network techs.

Advanced monitoring systems can provide a Human Machine Interface for all of the protocols within your network. These systems combine your Modbus alarms with alarms from all of your other protocols.

By bringing your Modbus alarms into a single screen with your other network alarms, you will save money and more efficiently monitor your network. With only one HMI workstation to monitor, you won't have to hire and train more staff to monitor a number of separate systems. This multi-protocol capability is important when looking for a Modbus HMI and monitoring system.

Additionally, an advanced Modbus master can be used for more than simply communicating with Modbus slave devices. When seeking a master for your Modbus network and other devices, you should look for a master that can bring your Modbus alarms and notifications from your other protocol devices into one master screen. This will help you monitor your network as efficiently as possible, eliminating the need for multiple operators and workstations to accomplish your network alarm monitoring.

With T/Mon LNX, you can interpret alarms from your Modbus devices, as well as alarms in over 25 other protocols.

With the Modbus Interrogator installed, the T/Mon LNX becomes the optimal Modbus HMI. The interrogator module supports discretes, analogs, controls, and remote provisioning of Modbus remotes and sensors. With this system, you will be able to easily switch between alarms and clears with many standard Windows controls. You will also be able to group your alarms into any group you need to better your monitoring.

T/Mon LNX provides a window view that pulls all of your Modbus and other alarms into one browser window, getting rid of the need for other monitoring gear and extra operators. With all alarms coming into one screen, you can be certain you'll never miss an important alarm when you were checking on another workstation.

The T/MON LNX can also double as a mediator. If you have SNMP equipment, legacy or proprietary equipment, or anything other equipment that is not Modbus but needs to be monitored, you can use the T/MON to mediate those protocols and send them to another device, such as an SNMP RTU.

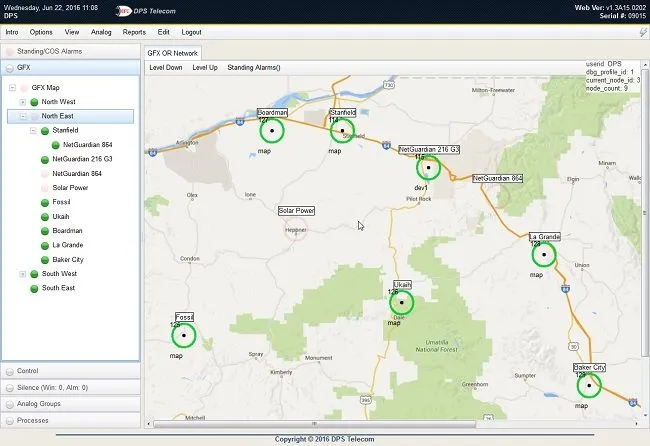

GFX allows you to map out your operations in a user-friendly way. By choosing your own images, you can create an interactive layout of your floor.

For instance, if you are a factory, you could have your entire process laid out. Each time a process is started, or if there is a problem, a light will flash at the exact area the issue is coming from. No more searching for issues in your machines. Know exactly where the problem is when it happens.

We offer three different levels of T/MONs, depending on the size of your network.

The T/MON LNX, mentioned above, is a multiprotocol, multifunction single-platform solution for all remote alarm monitoring uses.

The T/MON SLIM can be used over LAN and Modem. It monitors up to 64 devices and 10,000 alarm points. Can be loaded with the Modbus Interrogator module to act as an HMI for your Modbus operations. Additionally, it supports a web browser and email alarm notifications.

And lastly, the T/Mon MINI provides centralized monitoring for up to 16 DPS alarm remotes (scalable to 64 remotes). This makes it a great test for a larger T/Mon deployment, and also a solid long-term option for monitoring smaller networks. Just as the first two T/MON alarm masters, the T/MON MINI can support the Modbus Interrogator module to mediate Modbus protocol into a human-readable language.

A Modbus network should be developed using the most advanced Modbus monitoring technology.

With advanced Modbus monitoring systems, you can provide automatic email and SMS notifications of all your alarms. With location and repair information sent directly to your technicians, you can handle network problems more quickly and efficiently.

The most advanced systems will also allow you to bring in alarms from other protocols and can display all of the important notifications in a single window that can be monitored by a single network operator.

Keep in mind that, to be able to get advanced technology with proven design, you need to first find a reliable vendor.

There are a few things that we - as a manufacturer of remote monitoring solutions - want you to know in order to get the most value of your investment.

First, think of us as your personal engineering department

Most vendors just want to sell you a part number.

Here, we are experts, and we make just about everything ourselves. That's why we can custom-tailor equipment to your specific needs.

We'll even help you develop your requirements if you're new to monitoring technology. We've done this a lot. The only thing you need to do is tell us what you need.

Don't be scared by our extensive product range

Because you can get custom products from us (which then become available as off-the-shelf options), our products range is predictable large. You might be confused by the sheet mass of available options, but that's exactly why we have expert engineers available on the phone. All you need to do is call us and tell us what you're trying to accomplish.

And don't take our word for it (you absolutely don't have to)

You're probably used to hearing outrageous claims from vendors. As you know, the best thing you can do to be able if what they're saying is actually the truth is to get independent opinions from other professionals like you. We have dozens of case studies from happy clients, and we can give you contact information for DPS clients in your industry. It is important to talk to someone who is already using DPS equipment.

Also, if you've decided to go with a Modbus solution for your monitoring needs, we do make sure to follow the all previous Modbus protocol best practices to be able to give you the best bang for your buck.

And, and as always, we're never more than a phone call - or email - away. If you have any questions (even if you're early in your research and don't need product information yet), simply contact us and we'll be happy to help you.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.