Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

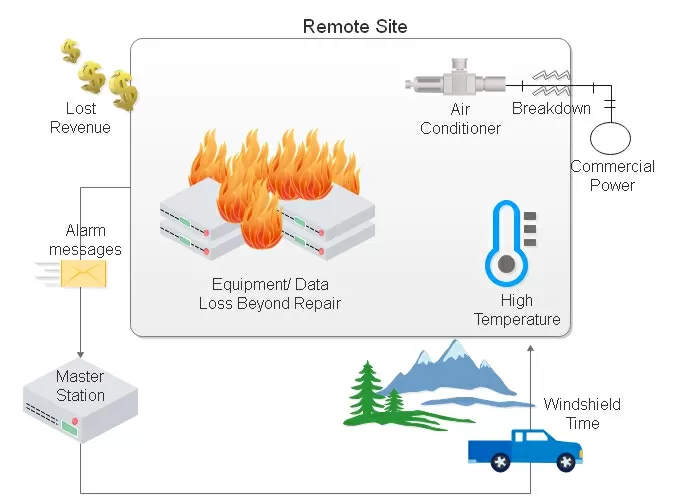

Reserve Your Seat TodayA failed AC unit at one remote site can sometimes mean hundreds of thousands of dollars are needlessly wasted.

It sounds dramatic, but for telecom providers and network operators, this scenario plays out more often than you'd think. A subtle failure at a remote location, often hours away from your NOC, can set off a chain reaction that ends with overheated equipment, service outages, and angry customers.

The harsh truth is: temperature is one of the most underestimated threats to network reliability. And when it goes unmonitored, it becomes an invisible killer (usually not literally, but that actually can become true in public-safety applications where 911 or police/fire radios are involved).

Your telecom gear is tough, but it's not invincible. Rack-mounted switches, routers, radios, power supplies, and batteries are all engineered to run within a safe temperature range. When ambient temperatures climb beyond that range, the damage begins - silently.

You might not see immediate failure, but here's what happens behind the scenes:

And if your team isn't watching, you may not even realize there's a problem - until gear starts failing, outages begin, and SLAs get breached.

One DPS Telecom client - an experienced telecom operator - lost an entire remote site because they didn't have temperature monitoring in place. Servers, switches, and power systems acted like space heaters in a sealed shelter, while no alarms were triggered. The result was hundreds of thousands of dollars in damaged gear and weeks of recovery time.

Most legacy temperature monitoring systems rely on discrete threshold alarms. These are the classic on/off sensors that only alert you once a set point has been crossed (e.g., 80 F).

The problem with that is it provides:

These systems force you into reactive mode. When the alarm finally goes off, you're already in crisis. By the time a tech reaches the site, the damage is likely already done.

In 2025 and beyond, this type of limited visibility just doesn't cut it anymore.

What if your system didn't just alert you when it's too late - but helped you see the problem coming?

You need a monitoring platform that:

That way, your team can make fast, informed decisions - before failures happen.

This is what modern temperature monitoring looks like. And it's not just a wish-list. It's available right now.

Many people go wrong by installing one sensor - maybe in the middle of the room - and calling it a day.

That's not enough. To really protect your infrastructure, you need multi-zone coverage. This gives you a complete picture of your environment - and the lead time to act before damage sets in. For the best results, place sensors:

This is where heat buildup happens fastest. Place sensors directly near your most valuable equipment - switches, routers, radios, batteries. These zones are often hotter than the ambient shelter temperature and should be your first line of detection.

Ironically, your monitoring system itself can become the weak link. If your RTU fails due to heat, you lose all visibility. A sensor here makes sure your eyes on the site remain open.

You need environmental context. Outdoor sensors help you anticipate rising internal temps due to heat waves, solar load, or wildfires. They also help detect issues like blocked ventilation or clogged HVAC filters when the inside and outside temperatures diverge abnormally.

Pro Tip: Monitor HVAC performance directly. Even better, power it from a protected circuit - not just commercial power. During outages, your batteries might keep the gear alive, but if the AC is offline, internal heat climbs fast, leading to thermal shutdown anyway.

When it comes to reliable remote site monitoring, the NetGuardian series stands in a league of its own. For example, the NetGuardian 832A G6 is designed for critical infrastructure and harsh environments, offering precision monitoring you can count on - no matter what.

This RTU is the gold standard for temperature monitoring for several reasons:

And yes, it's RoHS-5/6-compliant for international regulatory standards. RoHS-6/6 compliance is also available if you need lead-free solder for your region or to comply with internal/contractual standards.

Whether you're managing one shelter or hundreds across your network, the NetGuardian 832A G6 gives you confidence that you're covered (even and especially in the dead of summer when HVAC systems are under peak load).

There are a few hidden threats that can cook your gear while you're not looking.

Your servers, switches, and rectifiers produce heat constantly. Without proper airflow or cooling, shelters can become ovens.

Summer heat waves, wildfires, solar exposure, and windstorms can all drive temperatures higher outside - and by extension, inside.

If you lose commercial power, your batteries will keep gear online - but your AC might shut down. That's when the "silent oven" effect begins.

Filters get clogged, compressors degrade, and systems work harder over time. Without monitoring, you won't know your AC is failing until it's too late.

These threats aren't hypothetical. They're happening today, all over the world. And without a solid temperature monitoring strategy, you're playing with fire.

Temperature monitoring isn't a luxury - it's your first line of defense.

Modern monitoring systems aren't just smarter, they're essential. They help you detect failures early, respond faster, and prevent catastrophic loss before it starts.

With the right sensor placement and a reliable RTU like a G6 NetGuardian, you can:

If you've made it this far, you now know your risks. You also know how to fix them.

Now, it's time to get your sites protected.

Call DPS Telecom at 1-800-693-0351 or email sales@dpstele.com to get a free consultation.

We'll walk you through your temperature monitoring options and show you how to protect your critical infrastructure.

Don't wait until the next heatwave.

Monitor smarter, respond faster, and sleep better.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...