Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayLarge-scale DAS (Distributed Antenna System) deployments are some of the most complex infrastructure projects in the telecom world. They're especially challenging when they're happening inside an international airport.

In those cases, you're working with multiple vendors and you have dozens (or hundreds) of sites spread out over miles. Worst of all, everyone "wants" real-time visibility, but nobody wants to spend hours configuring incompatible systems.

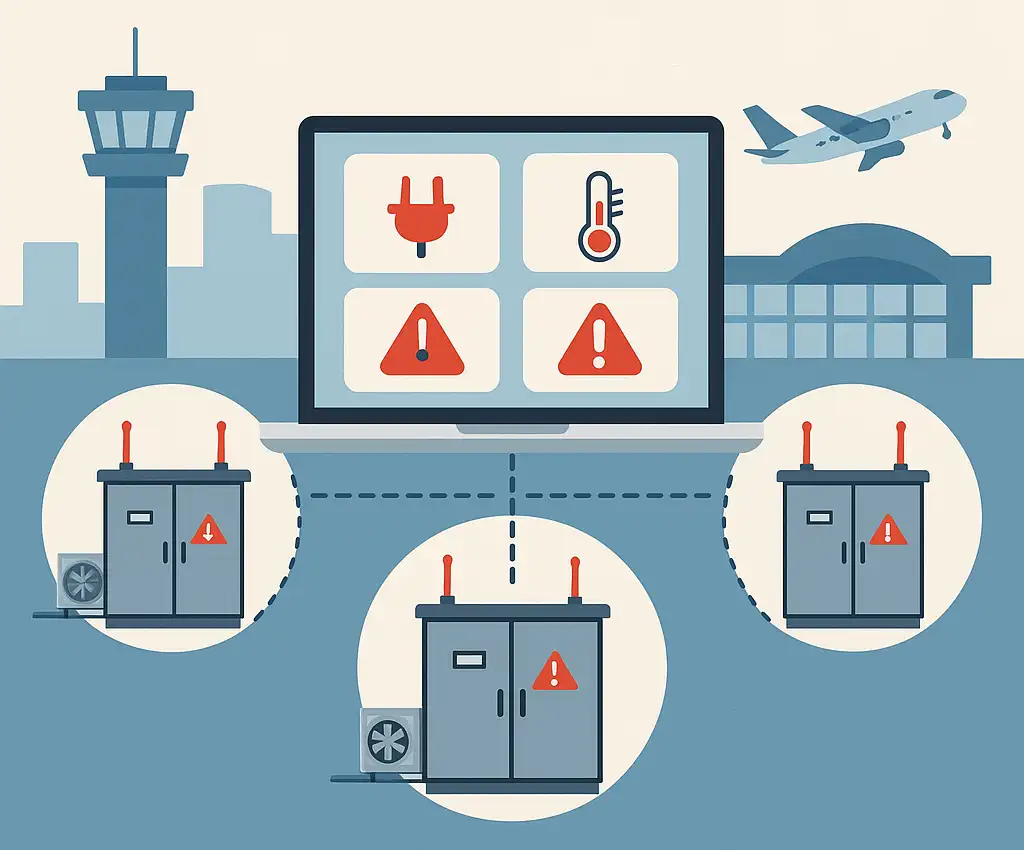

This is the exact situation one of our clients was facing recently. They were tasked with building a brand-new, carrier-agnostic DAS at one of the busiest airports in the United States. It's the kind of high-stakes environment where any failure (HVAC, power, comms) results in downtime for airline staff, gate agents, public Wi-Fi, and private carrier services. Stalled air traffic quickly stacks up during any kind of an outage.

The job was clear. They needed to tie together a diverse array of equipment (including CommScope DAS gear, Nokia radios, and Vertiv power supplies) into a unified monitoring system.

The goal was to have one interface with zero drama where all equipment is accounted for.

Let's walk through what made this project challenging, how attempts at a solution weren't working, and how to design a monitoring system that will actually work for you.

The project was massive in scope. At the heart of the system was a primary DAS head-end located in the one core section of the airport.

This room housed key third-party gear as well. Supporting this gear were nearly 40 tons of HVAC cooling, along with a variety of dry contact alarm outputs and standard environmental sensors like high/low temp and intrusion detection.

Beyond that centralized head-end, the airport featured over about 75 individual, climate-controlled DAS cabinets scattered throughout different terminals. Each cabinet included a third party power shelf and localized alarm points: AC fail, HVAC issues, and physical intrusion.

These weren't just standalone installations. The client needed all of these to report back to one unified monitoring platform that could handle both local alerts and aggregated network visibility.

If something failed (power, cooling, or equipment), they wanted to know about it immediately and from a single screen. The problem? No vendor made this an easy goal to achieve.

The most common approach for projects like this one is to rely on the "monitoring tools" built into the equipment itself. That's fine in theory. In practice, it almost always leads to problems.

For starters, integrated monitoring is typically pretty limited. It might send out basic SNMP traps or support dry contacts, but it's not designed to scale across dozens of cabinets and multiple gear types.

Each vendor wants you to use their software, which leads to a cluster of separate dashboards that don't talk to each other. If you've ever tried monitoring DAS gear from multiple manufacturers at the same time, you know how frustrating that can be.

Then there's the issue of visibility. Managing individual alarms across multiple screens is both inconvenient and dangerous.

These separate systems increase the chance that something slips through the cracks. Whether it's a failed HVAC unit or a power supply going offline, missed alarms in an airport environment are simply unacceptable.

And finally, there's the business side. Many "modern" solutions are cloud-based and carry recurring license fees. That might work for some industries, but when you're installing gear on-premises and building out a long-term capital project for a carrier, recurring fees are a no-go.

You don't want to "rent" your monitoring. You want to own it.

What our client needed wasn't a temporary patch or a vendor-specific workaround. They needed a platform that could centralize the entire system - from the power system in the head-end room to the dozens out in the field. They wanted one unified dashboard that reported on power status, temperature alarms, intrusion events, and anything else that might compromise uptime.

They also wanted clarity on ownership. From the very beginning, they made it clear: "Once we pay for it and have it set up, we want to own it."

There was no interest in platforms that required annual renewals and shut off functionality unless subscriptions were kept active. The solution had to be fully functional out of the box, with only optional maintenance/support fees.

On top of that, the system had to be easy to propose and explain internally. Since the client was packaging the full DAS system as a complete deliverable, they needed clear documentation, transparent pricing, and diagrams that showed exactly how the monitoring would function.

From the first conversation, it was clear we could help. We've dealt with these kinds of third-party devices many times before. And we've built entire alarm monitoring architectures that span hundreds of sites. This one fit right into our wheelhouse.

We proposed a solution built around our NetGuardian RTUs, which were installed at each of the remote DAS cabinets. These RTUs support both dry contact inputs and SNMP, making them perfect for monitoring local power shelves, temperature sensors, and intrusion alarms.

Depending on cabinet size and layout, we offered different mounting styles, including DIN rail and wall-mount options, to ensure clean, reliable installs.

At the central head-end, we connected to one of the third-party devices via its alarm interfaces - building or modifying templates as needed to ensure complete coverage of all relevant alarm points. If anything needed clarification, we flagged it in our proposal so the client could easily confirm or provide additional info.

For system-wide visibility, we tied everything into a central T/Mon master station. This gave the client a single interface to view the status of every DAS cabinet and the head-end in real time.

T/Mon also allowed for alarm filtering, notifications, and historical logging, with integration options for any existing SNMP-based network management systems. If they already had a NOC tool they liked, we could feed our alarms directly into it.

We understand that when you're managing a project this large, the last thing you need is another vague quote or one-page price list that leaves you with more questions than answers. That's why we spend a lot of time talking with you before writing up your proposal.

Instead of just sending over part numbers, we include a written summary that outlines what we heard during the planning call. We confirm the goals, recap the system layout, and explain how our solution addresses each requirement. We include custom network diagrams so you can visualize how everything connects, and we highlight any open items that still need clarification.

We also split out every line item in the pricing. That way, you can see exactly what each part of the system costs and adjust your scope as needed. If you're piecing together a larger proposal for an end-client, this clarity can make all the difference.

For this project, we had a first-draft proposal in the client's inbox within 24 hours of the call. The proposal included diagrams, technical notes, and open questions clearly marked. That kind of fast turnaround and documentation made it easy for the client to move forward with confidence.

One question came up during the conversation: "What happens after we deploy - are there any recurring costs?"

The answer was simple: There are no recurring costs just to keep the system running. DPS systems are on-premises, perpetual-use solutions. Once you buy it, it's yours. There are no hidden license renewals, no required subscriptions, and no features that vanish if you don't pay again.

We do offer optional maintenance agreements - particularly for T/Mon software updates - so your team can stay current with updates and patches. We keep that pricing straightforward:

Remember, basic technical support (provided by our engineers at our California headquarters) is included free with any purchase.

That kind of pricing makes it easy to align with contract terms or offer ongoing support as part of your bundled service to clients.

By the time we finalized the proposal, our client had everything they needed:

Every piece of gear was accounted for. That means no alarms will be missed and no one has to worry about a surprise invoice 12 months later.

If you're planning or deploying a distributed antenna system - especially across multiple buildings or vendor platforms - DPS can help you do it smarter.

Regardless of the manufacturer you work with, we have the tools to unify your alarms, simplify your management, and eliminate recurring costs.

You can call us to discuss your goals, walk us through your architecture, and we'll put together a tailored proposal (with diagrams, documentation, and pricing) within one business day.

Ready to get started?

Call us now at 559-454-1600

Or email sales@dpstele.com

Let's build a monitoring system that works for you (not the other way around!).

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...