Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayCovering 2,800 square miles, Baca Valley cut costs with remote monitoring

| Field | Details |

|---|---|

| Industry | Rural Telecommunications |

| Company Type | Independent Telephone Company |

| Geography/Coverage | 2,800 sq. miles, rural New Mexico |

| Primary Challenge | High costs from remote site visits (12-70 miles) |

| Solution Deployed | DPS DPMs with T/MonDL software |

| Key Result | Reduced site visits, lower vehicle and labor costs |

| Implementation Timeframe | 5 years (ongoing expansion) |

| Products Used | Discrete Point Modules (DPM), T/MonDL software |

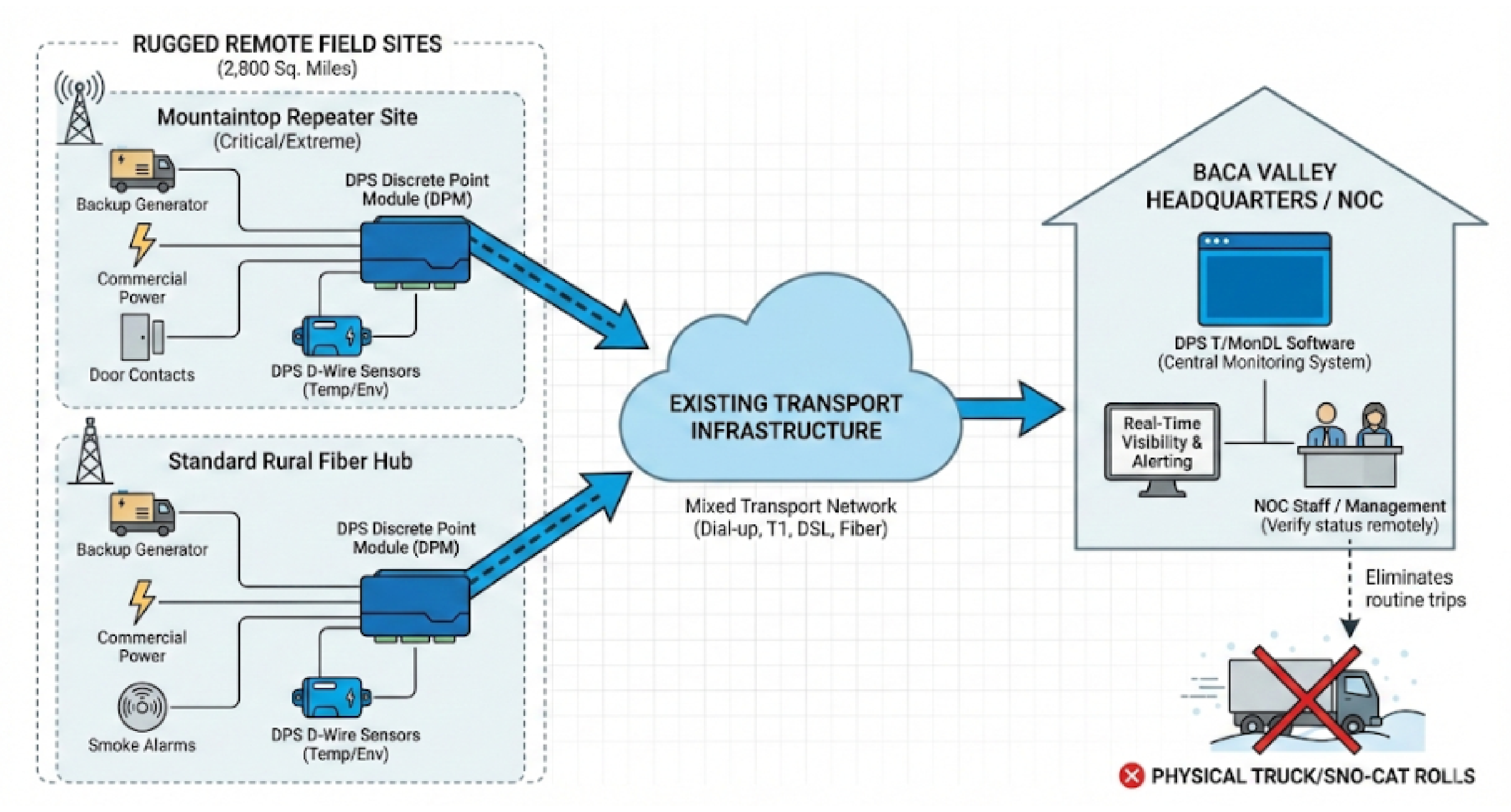

Baca Valley Telephone Company serves subscribers across 2,800 square miles of rural New Mexico. The company delivers dial tone and operates Sierra Communications, offering cellular service, Internet access, and business systems from northeastern New Mexico to southeastern Colorado.

Baca Valley's remote sites sit 12 to 70 miles from headquarters across rugged terrain. The mountaintop site requires four-hour round trips for just nine miles. Winter access demands Sno-Cat travel through five to six feet of snow. Summer requires 4x4 with chains. Each site visit costs several hundred dollars. Without monitoring, visits occurred two to three times weekly.

"The cost for one trip is several hundred dollars. When you do that three times a week, it's very expensive."

Baca Valley deployed DPS Telecom Discrete Point Modules at critical sites, reporting to T/MonDL software. The system monitors power status, generator operation, temperature ranges, smoke alarms, and door contacts. Paul Briesh attended DPS Factory Training to evaluate transport options for 25 sites and ensure the solution matched their operational needs.

DPS engineers provided hands-on consultation during Factory Training. The solution accommodated Baca Valley's existing infrastructure, supporting dial-up, T1, DSL, and fiber transport options without requiring costly network upgrades.

| Phase | Details |

|---|---|

| Initial Deployment | DPS equipment was installed at the most critical buildings, including fiber hubs and the mountaintop repeater site. |

| Training and Consultation | Briesh attended DPS Factory Training Event to work with engineers Chris Hower and Chad Linnenbrink on company-specific requirements. |

| Standardization Planning | Baca Valley evaluated transport options for 25 sites and planned NOC integration for after-hours and weekend monitoring. |

| Ongoing Expansion | The company continues expanding coverage beyond just fiber hubs to include sites serving smaller subscriber groups. |

Baca Valley now verifies power and generator status remotely instead of sending technicians on four-hour trips. The company eliminated most routine site visits, reducing vehicle wear, fuel costs, and labor expenses while maintaining reliable service to remote locations.

| Metric | Result |

|---|---|

| Site Visit Reduction | Eliminated two to three weekly trips to mountaintop location |

| Cost Savings Per Site | Avoided several hundred dollars per eliminated trip |

| Safety Enhancement | No dangerous winter Sno-Cat trips for routine checks |

| Operational Efficiency | Real-time status visibility without windshield time |

"I can tell, when these alarms come in, that we've gotten way more efficient, because we don't have to send somebody so often to these sites."

Paul Briesh, VP and General Manager, Baca Valley Telephone Co.

| Benefit | Description |

|---|---|

| Eliminated Windshield Time | Reduced routine site visits by monitoring remotely, saving hours and costs |

| Standardized Infrastructure | Single monitoring platform scalable across all 25 sites without learning curve |

| Improved Safety Standards | Avoided dangerous trips to mountaintop sites during severe weather conditions |

| Real-Time Visibility | Instant power, generator, and environmental status from any location |

Remote monitoring device for power, environmental, and alarm conditions

T/Mon Remote Alarm Monitoring System

Central monitoring software with dial-up and multiple transport options

Temperature, humidity, and environmental monitoring sensors

Rural sites can use multiple transport options including dial-up, T1, fiber, DSL, or cellular connections. DPS equipment supports all these methods, allowing telecoms to use whatever infrastructure they already have in place. Baca Valley uses dial-up at some locations and fiber at others.

For Baca Valley, a single site visit cost several hundred dollars and took four hours. Without monitoring, their mountaintop site needed visits two to three times per week. Remote monitoring eliminated most of these trips, paying for itself within months through reduced fuel, vehicle maintenance, and labor costs.

Yes. Baca Valley started with old Mountain Bell equipment from the 1970s and has upgraded over decades. DPS equipment integrates with legacy systems and supports multiple protocols, making it suitable for telecoms with mixed-age infrastructure. The flexibility allows gradual modernization without replacing everything at once.

At minimum, monitor commercial power status, backup generator operation, and temperature ranges. Baca Valley also monitors smoke alarms and door contacts. Future plans include rectifier monitoring and remote gate controls. The specific needs depend on your equipment and climate challenges.

Baca Valley's mountaintop site houses radio repeaters for county sheriff, EMS, and fire departments. Remote monitoring ensures this critical public safety equipment stays operational without requiring dangerous trips during emergencies or severe weather. They can verify generator status remotely when commercial power fails.

If your team spends hours traveling to remote sites for routine checks, remote monitoring can reduce costs while improving reliability. Let's discuss how DPS solutions fit your network.

Or call us: 800-693-0351