Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayHVAC (Heating, Ventilation, and Air Conditioning) systems are responsible for keeping your sites at an appropriate temperature so your vital gear doesn't overheat - or get too cold. Systems can vary in size and quantity depending on the size of the site and the amount of equipment being affected.

With such an important task, it's critical to monitor your remote HVAC units. This can be challenging at remote sites, which is why finding the right remote site monitoring equipment, such as DPS Telecom's reliable HVAC monitoring solutions, is a must.

When you overlook the importance of HVAC monitoring and management, it's only a matter of time until a problem occurs.

Two different situations can happen when you don't monitor your HVAC at your remote sites:

You don't notice that a site is overheating

You short-cycle HVAC or generators until they die

If you perform effective remote furnace monitoring at your sites, you'll most likely see a threat before it causes actual damage.

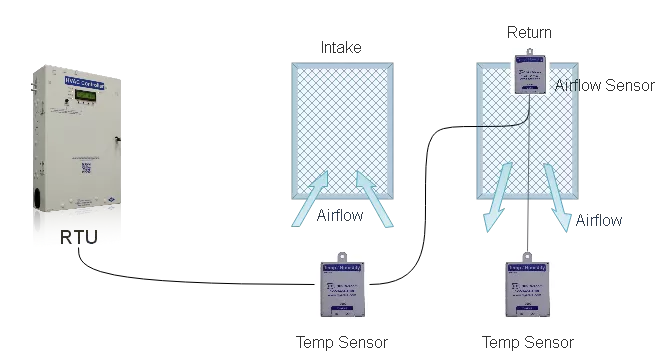

Monitoring your HVAC system is not rocket science. You can do it with an NetGuardian RTU and simple sensors, such as temperature and airflow

When you connect these simple sensors with history logging in an RTU, you can count HVAC cycles and look for opportunities to reduce them.

Something to keep in mind when setting up your HVAC system is power waste. This can come in a few different forms:

You start cooling at a lower temperature than necessary

Even your most sensitive gear will be able to function without issue at a higher temperature. These higher temperatures would make a person uncomfortable, but why let human comfort drive your default temperature settings at unmanned sites?

The simplest possible data analysis on decent HVAC logs - and a review of your equipment specs - will show you opportunities to expand your temperature settings.

You have a wider cooling window than necessary to prevent short cycling

To use your HVAC in the best possible way, you have to balance two opposite factors.

First, you want to have longer cycles so you don't cycle on and off too much.

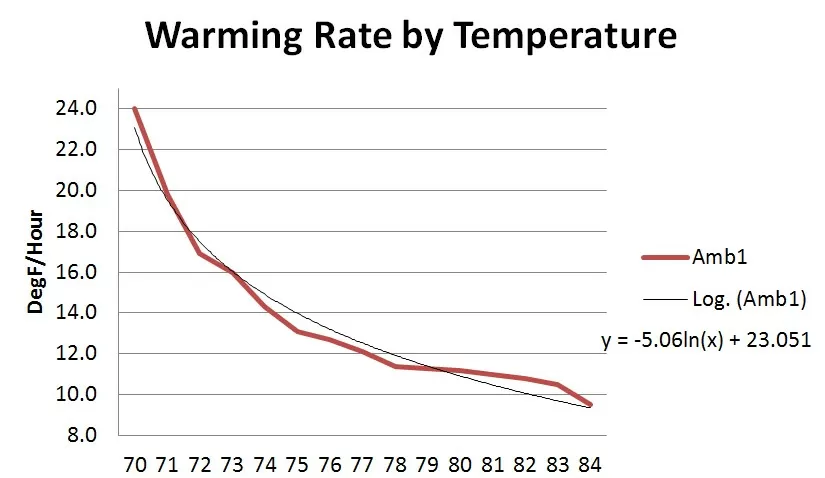

On the other hand, you should want shorter cycles so you won't be excessively fighting to maintain really low temperatures. This is a crucial point because the further you push temperatures down, the faster they'll go up in a warm climate.

These two factors are why you need to strike a balance between long HVAC cycles and short ones.

Clogged filters and other failures are limiting your HVAC throughput

If your HVAC units have clogged filters or otherwise aren't cooling effectively, they're not doing their job. This means that now you're running them longer to get the same job done, which is a huge waste.

Monitoring the airflow at your AC vents is an accurate and cost-effective method of getting real-time data about the condition of your air filters.

If you work in a very cold climate, keep in mind that all of this information also applies in terms of heating efficiency. The logic remains the same, you're simply reversing all of the thermodynamic math.

Now that we've reviewed the most common causes of lost profits caused by a lack of network monitoring, it's time to learn how you can deal with them. Let's break down some of the solutions:

It's important to have the peace of mind of knowing if you're starting and stopping cooling (or heating) cycles at the right temperatures. You need to have good information to be able to adjust your power consumption to the amount of cycle wear that is being reflected in your HVAC unit's lifespan.

Each additional degree of cooling you demand vs. the outdoor air increases the amount of electricity you consume. Each degree you give up offers a significant reduction in power consumption.

In addition to looking at your HVAC cycling, you can also chart analog values and discrete counts to see long-term progressive tendencies.

By seeing this data spread out across time, you'll have a better overall perception of your network performance.

Now you know that it's key to run your HVACs only when it's necessary - to be as efficient as possible. However, efficiency can be hard to determine. After all, how do you actually spot opportunities to save money?

You have to do long-term analysis of your gear, of course, but that requires comparing temperature trends, HVAC run times, and energy bills. This is a hard process if you don't have a system that automatically logs temperature and HVAC run times.

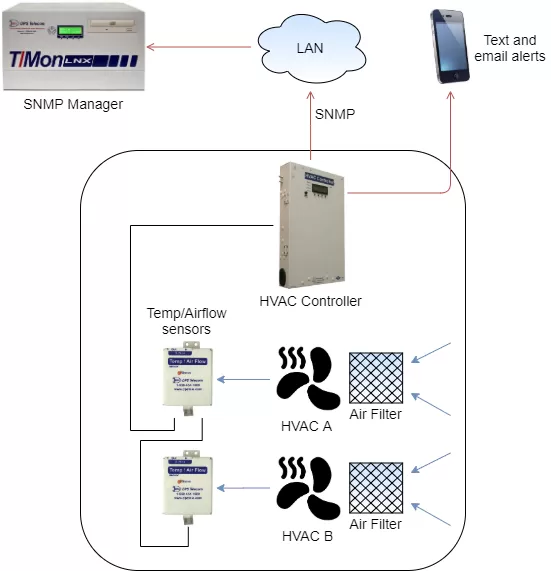

You could skip the complicated logging and analysis altogether and get a smart controller from DPS Telecom. This device will remotely control your HVAC systems to run at an optimal level - the best ones even do it automatically, making adjustments as necessary.

At DPS, we get a lot of inbound calls after the caller has already had a major failure. That's natural, but you don't have to fall into this same trap.

The DPS HVAC Controller is a device designed specifically to control and monitor HVAC systems. It provides you with all the benefits that NOC technicians need in a centralized location. It's simple to install, configure, use, while also being capable of supporting D-Wire sensors.

Do you have any questions or want to understand further how you can remote control your HVAC system? I'm just a call away!

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...