Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayThe best temperature monitoring system depends on the specific needs of your operation and, to a certain extent, your industry.

Let's walk through all of the major scenarios where temperature monitoring is required and look at the system that best fits each one.

When I go home at the end of the day after working with DPS clients on monitoring projects, I'm a consumer just like anyone else. I enjoy working on hobby projects and using modern "smart home" systems to keep tabs on my house.

Like almost anything, however, we all need to separate the needs of a consumer from the needs of a major business or public agency.

If you waste a few dollars on your home heating/cool or burn up your gaming PC, that's a problem with very limited scope. That's what makes consumer-grade equipment, which works pretty well most of the time, just fine for the task.

Compare these examples with the risks of overheating equipment or fire at a police or fire radio tower. Think about what would happen if you have thermal runaway of your UPS batteries. These are dire situations that can cause hundreds of thousands of dollars in damage and even put lives at risk.

It's for this reason that it's important to remember: business and government enterprises have fundamentally different requirements from consumers. This is entirely based on the differing importance of uptime that allows massively different cost justification.

So, if you're here because you need to monitor home PC temps or track your home air conditioner, you'll probably have good luck with any of the major commercially available options from $50-$300. That's what I do in my own home. The "best" option will depend on your personal budget and how the particular features align with your project goals.

If you're here because you have remote sites that need the best temperature monitoring system possible, that's what I'm here to talk about today. Let's get started now.

One of the biggest questions I get asked when talking about temperature sensors is wired vs. wireless. In many facets of life, what was once wired 30 years ago is now wireless. That same option now exists for temperature sensors, but it's certainly not true that wireless sensors are always better.

This might sound backwards to you. Let me explain.

Decades ago, it was common to monitor temperature with simple discrete sensors that operate much like your home thermostat. These are "digital" in the sense that there only two possible states: "on" or "off".

Compare a simple thermostatic "click" with a thermometer that can tell you the precise temperature at any time. That thermometer is "analog" because it has a whole range of possible outputs (anything between the min and max value).

Although "analog" often feels older than "digital" to our ears, it's important to think of these terms in an engineering context when talking about remote temperature monitoring.

As technology has advanced, we've gotten to the point where the incremental cost of an analog vs. digital temperature sensor is really only a few dollars. That makes it silly to pinch pennies for almost any application, and certainly for any corporate, government, or public-safety project.

What good does it do for you to have the best temperature sensor in the world if you don't know when the temperature reading becomes a problem?

If you're going to monitor temperature at unmanned locations, your system must necessarily involve the reporting of data from your multiple locations to your central monitoring center.

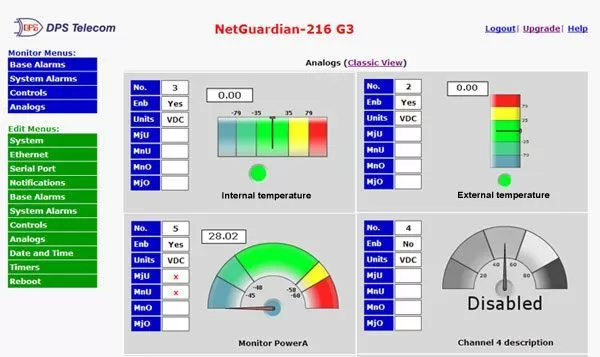

This can take a few forms. Your temperature monitoring system should have a web interface. More advanced, it can have an API for custom integrations with other systems.

One of the best alerts for small and medium projects are simple SMS (text message) or email alerts. These are simple notification types that almost everyone understands already and monitors religiously.

If you're in a very large network (ex. a power utility spanning multiple states), a protocol output like SNMP is a great way to integrate temperature and humidity monitoring into your overall remote management setup. When you have hundreds or thousands of sites, you usually want your notifications to be managed by your central monitor system and not your individual temperature monitoring devices.

Your temperature monitoring system should also allow you to set temperature thresholds and receive alerts when those temperature thresholds are exceeded. This is especially important if your temperature data is critical to safety or operations (like for a telecom hut or data center).

As you shop for different temperature sensors, you'll see that many also include humidity sensing. My clients have traditionally been split about this. Some value the extra visibility. Others admit that they don't really care about humidity because other types of alarms would alert them first anyway.

You'll probably want to think about your climate here. Some places have so little humidity that it's liable never to be an issue. On the other hand, I had a client in the Bahamas who was able to precisely monitor a site during hurricane Irma using a combination of humidity and water-level sensors.

Let's have a 15-minute discussion about your monitoring goals. I'll listen to what you're trying to accomplish, then help you make judgements using my 16 years in this industry.

Just call 1-800-693-0351 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...