Download our free SCADA tutorial.

An introduction to SCADA from your own perspective.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

SCADA (Supervisory Control And Data Acquisition) systems are used in industrial settings to monitor vital gear and environmental values. SCADA systems can be used to monitor many different kinds of gear, such as PLCs, RTUs, and Masters in many different kinds of environments. In fact, you're likely to find SCADA technology in public utilities, refining actions, major telecoms, transportation/transit companies, and more.

If a company has a computer network that's spread out across a wide-area, they'll use a SCADA system to monitor and control important aspects of that network and the revenue-generating processes that it supports. In short, SCADA helps smart companies to monitor, manage, and control their facilities -- on-time, on budget, and with increased profitability.

Imagine what it would be like to manage a large-scale operation without the advantages provided by SCADA systems, you'd instantly be reduced to guessing. You wouldn't know the temperature, humidity, fuel levels, and gear status you need to keep your operation running smoothly.

This is exactly what makes SCADA systems so vital. No matter what the size of your organization, you need to leverage SCADA systems if you want to manage actions that are spread out across a large space. If you don't us SCADA systems you'll frequently find yourself driving to remote sites just to get a simple status check, flip a switch, or push a button.

But just because SCADA systems are so important doesn't mean that you can ignore your basic responsibility to research before you buy.

You must be careful or you might end up with a system that is not much help to you at all. SCADA has the potential to save you a lot of money and boost your profitability, but a large percentage of SCADA projects that are started each year turn into quagmires of cost overruns and delays.

Perhaps more likely, you'll get a mediocre system that meets your current needs - but doesn't have the horsepower and growth potential to meet your needs 10 years from now.

Use the detailed information in this article to make informed SCADA decisions. By spending just a few minutes to read this article now, you could potentially save yourself weeks or months of wasted effort later by avoiding common SCADA pitfalls.

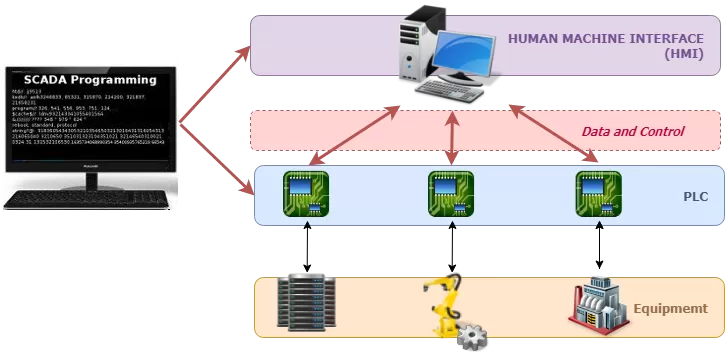

SCADA doesn't just refer to one technology, but rather to a single kind of application. SCADA systems collect data from a primary system in order to control that primary system.

This SCADA systems definition has two main components: the process you want to control and monitor, and a system of electronic gear that allows you to control and monitor that process from a central location.

As you can tell by this broad definition, SCADA systems can be built from many different types of technologies and protocols and still fall under the umbrella of "SCADA systems".

SCADA systems can be used to monitor and control any kind of gear, process, or operation. Most commonly, they automate complicated industrial processes where manual monitoring and control by human staff just isn't feasible. This includes:

These are only a few common examples, however. SCADA systems are a global reality.

The SCADA transportation of information allows you to keep a very close eye on your operations. You can deploy sensors and control relays at important places to get a highly detailed "birds eye view" of your revenue-generating activities. With SCADA, you will incur less cost while doing more. This is the definition of a profitability boost.