Download our free SCADA tutorial.

An introduction to SCADA from your own perspective.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

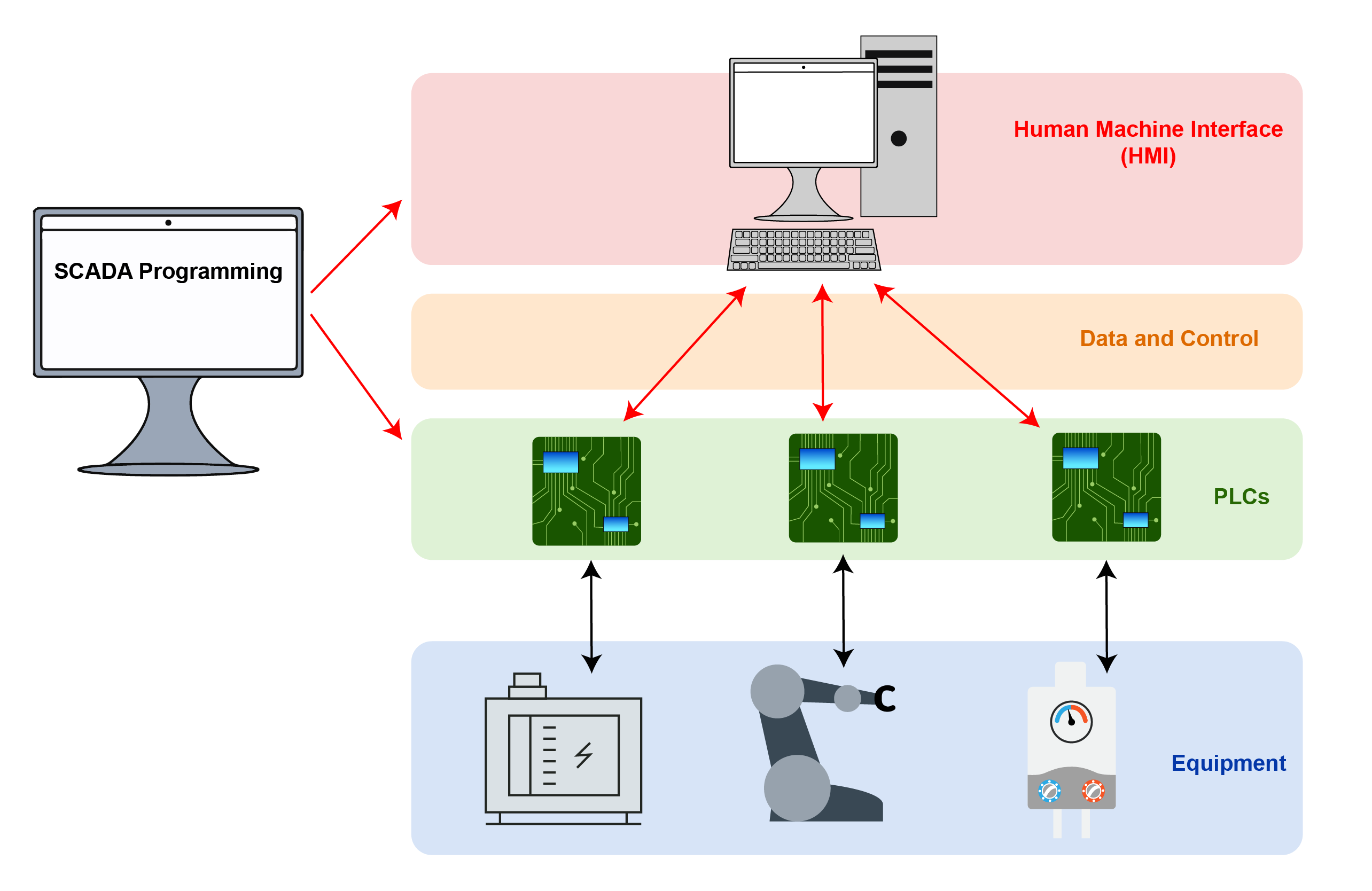

Reserve Your Seat TodayA Supervisory Control and Data Acquisition (SCADA) system, at the machine level, consists of a central station for gathering data and managing the overall operation. It also has sensors (these could be RTUs or PLCs) placed near to where the action is. The remote terminal units RTU or the programmable logic controllers PLC collects the information locally and then passes it on to the central station. This can be located several miles away.

To fully understand the components, let's break them down:

The interaction between these components ensures seamless data flow. PLCs and RTUs send collected data to the remote or on-site HMI, which interprets it for human operators. This integration allows for efficient monitoring and control, regardless of the distance from the central station.

If you have specific questions that need answering now, let us know.

RTUs and PLCs today are capable of controlling the actions within their range of vision through closed-loop feedback systems. The central station oversees the overall performance of the one or more RTUs/ PLCs under its control. SCADA systems also allow staff or supervisors to change the settings as appropriate at the level of the RTU or the central station. Alarming conditions like high temperature can then be stored and displayed as real-time data.

The dangers of free SCADA software

PLCs and RTUs are the heart of SCADA systems, enabling real-time industrial monitoring by collecting data from sensors and machinery, executing automated responses, and transmitting critical information to centralized control centers. Acting as local control hubs, these devices bridge the gap between remote equipment and your SCADA interface, reducing the need for constant on-site supervision.

RTUs and PLCs consolidate data from multiple sources, communicate through secure protocols like SNMPv3 and Modbus, and interact directly with field devices such as pumps, motors, and HVAC systems. This integration ensures seamless operation, minimizes downtime, and enhances operational efficiency. Advanced SCADA programming languages like Ladder Logic and DNP3 further expand their automation capabilities.

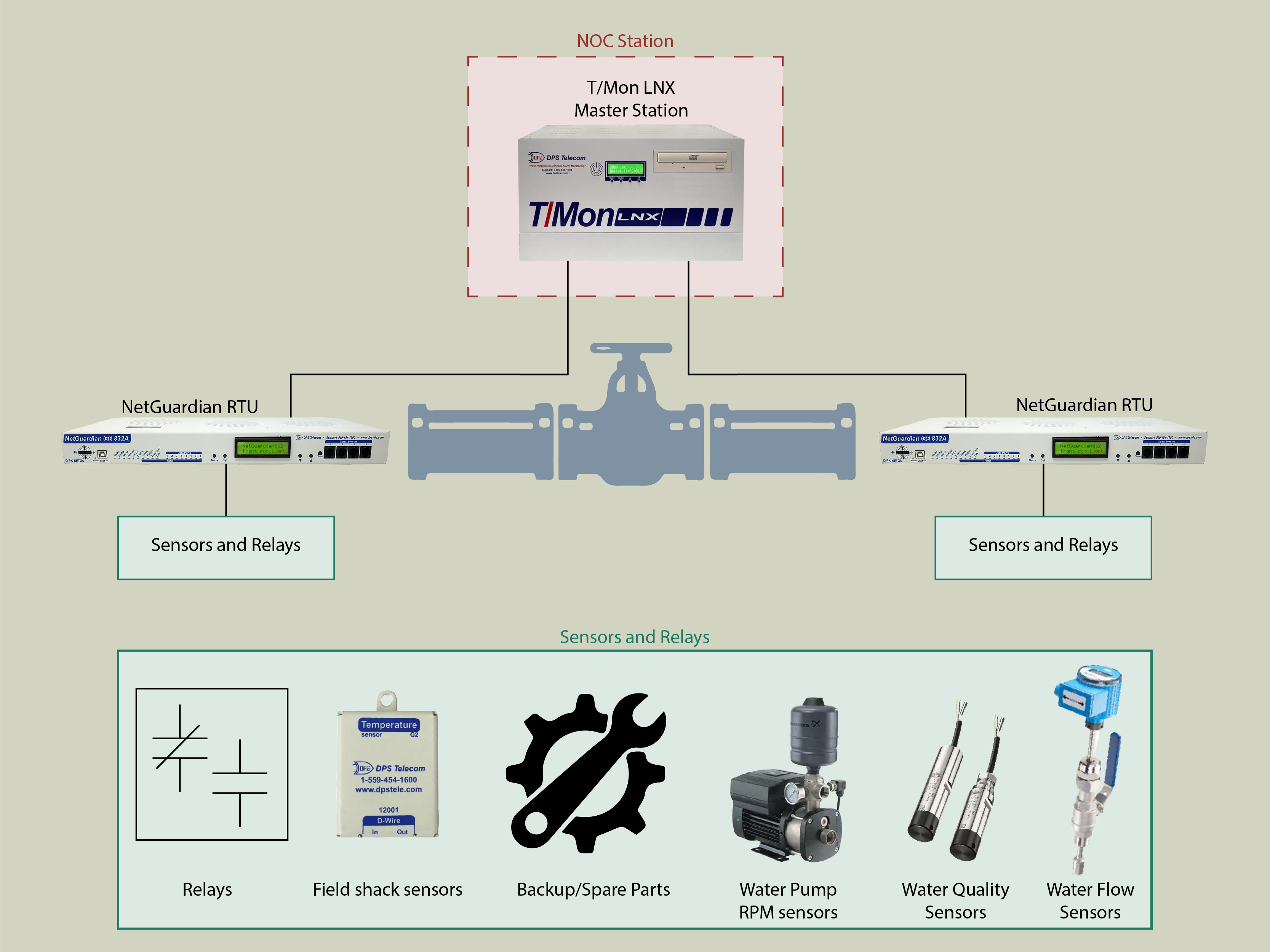

DPS Telecom's NetGuardian RTUs and T/Mon master stations excel in SCADA environments by supporting multi-protocol compatibility, rugged reliability in harsh conditions, and scalable expansion options. These features make DPS solutions ideal for boosting network efficiency and ensuring 24/7 operational uptime.

A client asked for a cost-effective SCADA system for the following requirements:

A basic solution for this scenario would include:

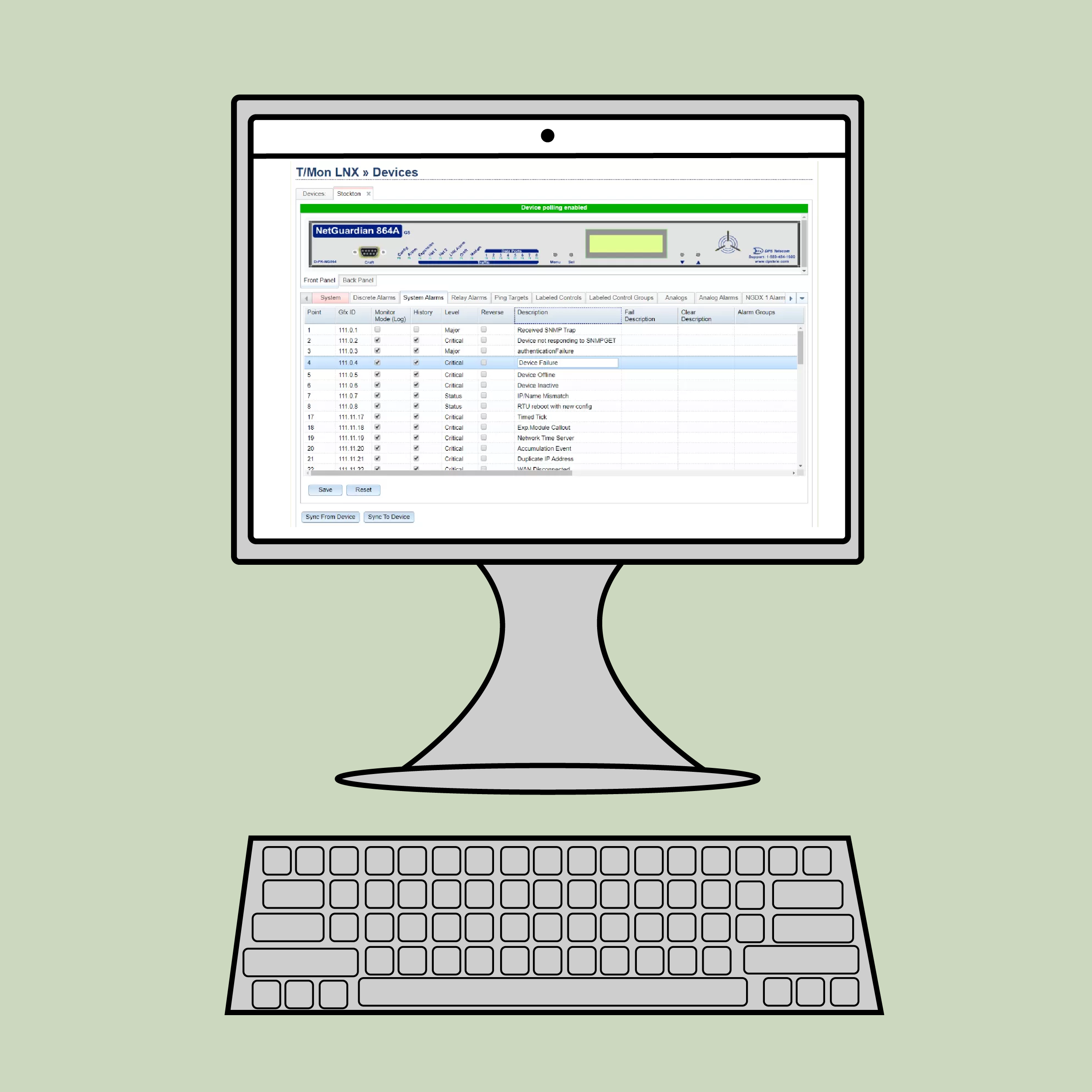

The T/Mon master station and NetGuardian RTUs would need to be "programmed" (configured/provisioned) in their own interfaces to complete this SCADA installment.

Real-world conditions must be switched to machine language and then into signals that humans can read, record, and analyze. Therefore, SCADA system development involves programming at various levels.

So what is SCADA programming? In SCADA programming, data is collected at the Remote Telemetry Unit (RTU) and has to be changed into signals, which is followed by reading this data that requires a Human Machine Interface (HMI). Often, this data also has to be grouped and stored (history databases) for trend and analysis work. As a result, unique database systems have to be developed. Networks and communication systems bring in more varied requirements.

Having a SCADA system that supports multiple protocols at all of its levels is advantageous for your system or network. With a SCADA system that supports multiple protocols, you'll have:

With more and more SCADA systems being deployed globally, the odds are increasing that you may be called on someday to program a system. What does it take to program a SCADA system?

The way you program depends on the system. It is common in manufacturing setups to design logic chains to be carried out when certain "trigger events" occur.

This is common in manufacturing. If you work with a large-scale network (telco, power utility, railway, government, oil and gas, etc.), it's more likely that you'll be working in simpler interfaces and won't really be "programming" in the traditional sense. Instead of coding in a text editor, you'll be using an RTU's web interface.

An RTU web interface is a great example of "configuring" a SCADA implementation rather than "programming." After you've wired some inputs into the RTU, you'll have to tell the RTU (via its web based interface) what to call each item.

Higher up the chain, you'll need to perform similar programming of your master station (HMI software). This is important because your master station brings together all of your RTU/PLC elements into a single view. "Programming" in a master/HMI context involves creating maps or diagrams that provide a view of your system in an emergency. You want to see exactly WHERE a problem is, not some code number or label.

For more information on web based RTUs, click here.

Most SCADA supervisory control systems are now programmed using standard interfaces whenever possible. Most programs are written in C, or a derived programming language.

As a SCADA professional, you are required to improve the functionality and performance of the software programs on your SCADA systems. This includes updating software and applying bug fixes and enhancements. Typically, any software in your system would be developed by the manufacturer or your RTU.

Why you should avoid SCADA programming software free downloads

To protect against threats, using various security measures is necessary. A few of the essential security components of a SCADA system include:

Supervisory Control and Data Acquisition systems technology is a more modern version of network alarm monitoring tech that's been used since the '60s. The broader term defining those systems is "DCS" (Distributed Control System). DCS have commonly been used for factories.

However, such systems are not effective in covering large areas like those used in gas transport systems. If you were monitoring a single plant, a DCS may suffice, but if you have a distributed network of industrial plants over miles of land, a SCADA system would be most beneficial.

SCADA has been specifically developed to meet requirements covering large territories. Therefore, such a system can be used in various industries and for industrial processes. This includes manufacturing, water and sewage, electric power generation, and mass transit. This is why SCADA programming plays such a big role in the system's development.

It can also be used for facility processes in private or public facilities. This includes buildings, airports, ships, or space stations. This is done to monitor and control: HVAC, access control, and energy use management, etc.

Even with all this being said, SCADA systems are being put into use with greater consistency in today's competitive manufacturing world. SCADA systems are used to perform data collection and control at the supervisory level. HMI's are typically seen as local user interfaces that allow staff to control the machine or process locally and perform SCADA programming work to customize the system.

Data collection begins at the PLC level and includes readings and gear statuses that are communicated to a master when needed. The system would then process data and format it in such a way that a control room operator using an interface terminal can make supervisory decisions that may be required to adjust or override normal PLC controls.

The system then processes this data, formatting it so that a control room operator using an interface terminal can make supervisory decisions that may be required to adjust or override normal PLC controls.

A SCADA system is versatile in the types of data it collects, including temperature, pressure, and speed from various plant equipment. This raw data is translated into comprehensible information, enabling operators to act effectively.

One of the strengths of a SCADA system is its ability to collect both live and historical data. Live data is crucial for real-time tracking and maintenance tasks, while historical data serves an important role in reporting and enhancing plant performance over time.

The tags (data) are collected locally in the SCADA software database or into a Historian (distributed database) to allow trending and other logical work.

This ensures that the data is readily accessible for analysis and decision-making.

Moreover, the system's design supports interoperability across different vendors' equipment, provided that the equipment supports accessible communication protocols. This feature is necessary for uniform information exchange across sites, allowing for seamless integration and data coherence.

The Fast Introduction to SCADA Fundamentals and Implementation by Bob Berry is a quick, 12-page introduction to SCADA. This guide shows how you can use SCADA effectively and profitably. Concrete applications and examples are included as illustration and to reinforce best practices.

Get Instant Access to SCADA White Paper

At DPS, we're totally focused on remote monitoring systems. We've worked on thousands of industrial automation projects that involve SCADA in one form or another.

That experience means that we have SCADA experts on staff. If you need more information how you can work with SCADA, give us a call or send us a message and we'll answer any question you have.

Next: SCADA tutorial from experts

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.